Judging method of boring state of hard rock TMB

A hard rock roadheader and hard rock technology, applied in special data processing applications, instruments, electrical digital data processing, etc. Problems such as the complexity of the rock mechanics process, to achieve the effect of improving the stress state of the cutter and improving the tunneling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

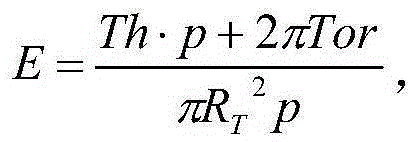

[0046] In the tunnel project of this embodiment, the structural parameters of the hard rock TBM used are as follows: 38 disc-shaped hobs with a constant section of 432 mm are installed on the cutter head, that is, the initial radius R of the hob is 216 mm, and the radius of the cutter head is 3.285 m. The sum of knife installation radius is 62.415m.

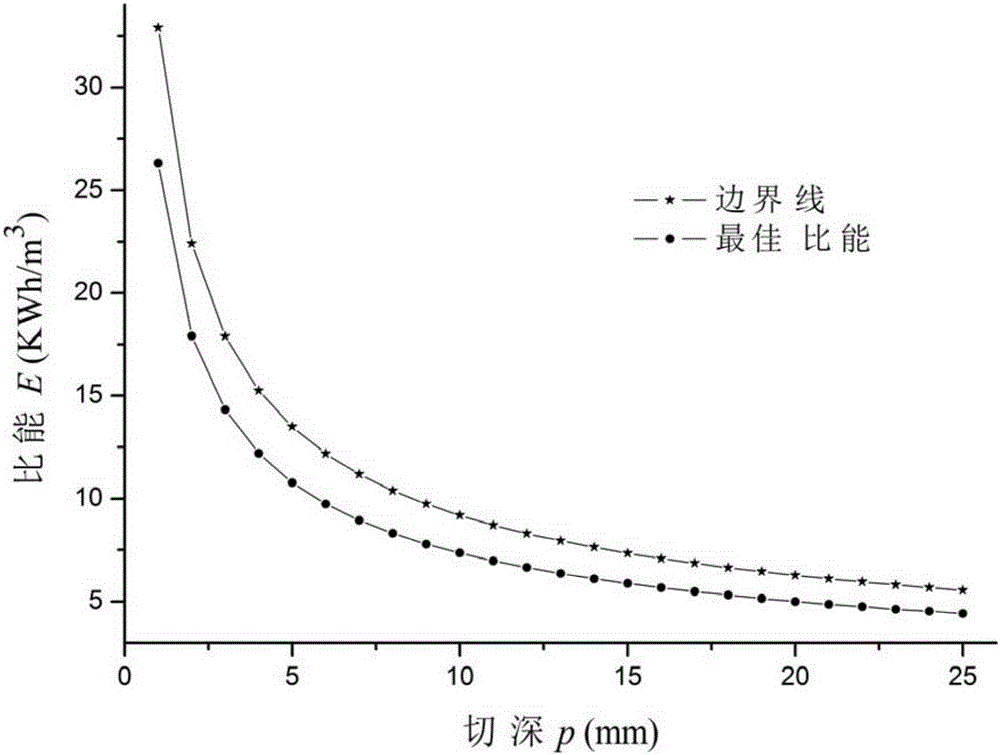

[0047] The surrounding rock is a broken rock formation with many joints. The detailed steps for estimating the specific energy of TBM excavation are given as follows:

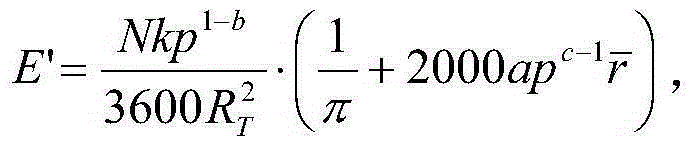

[0048] In the first step, according to the relationship (1) between the thrust of the hob and the depth of cut during the normal tunneling process of the hard rock TBM, which is determined by the rock mass joints and rock mechanics parameters, the inversion identification of the experimental data is used to determine k = 172.89, b=1.07, then formula (1) becomes:

[0049] f n =172.89p 1-1.07 =172.89p -0.07

[0050] In the second step, in this embodiment, all t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com