A manufacturing process for aviation motors

A manufacturing process and a technology for using motors, which are used in the manufacture of motor generators, electrical components, and electromechanical devices to achieve the effects of low friction coefficient, enhanced internal connection strength, and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0028] The aviation motor manufacturing process provided by the present invention includes the following contents:

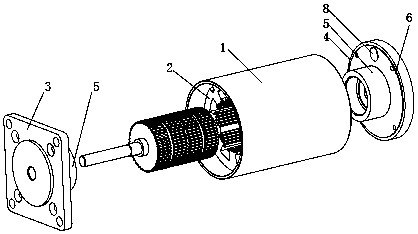

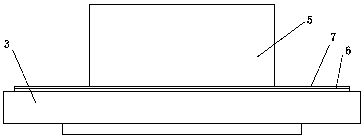

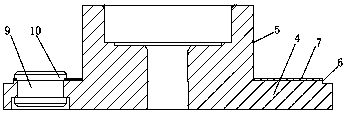

[0029] A. The parts that make up the motor are processed, including the casing, front end cover, rear end cover, stator core, and rotor;

[0030] B. Wind the enameled wire into the stator slot;

[0031] C. Assemble the above parts to form a motor;

[0032] D. Heating and heat-insulating the assembled motor, and then placing it in a vacuum chamber for degassing, so that the air in the material itself of each part of the motor can be discharged.

[0033] The heating temperature, the holding time, the size of the vacuum degree and the vacuum storage time are determined by actual needs, so that it is as close as possible to the use environment. The casing, front end cover and rear end cover should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com