High-separation low-temperature sausage casing membrane

A casing film and high-barrier technology, applied in sausage casings, food science, applications, etc., can solve the problems of decreased freshness, oxidative discoloration, high return rate, etc., and achieve the effect of preventing microbial invasion, not easy to oxidative discoloration, and extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

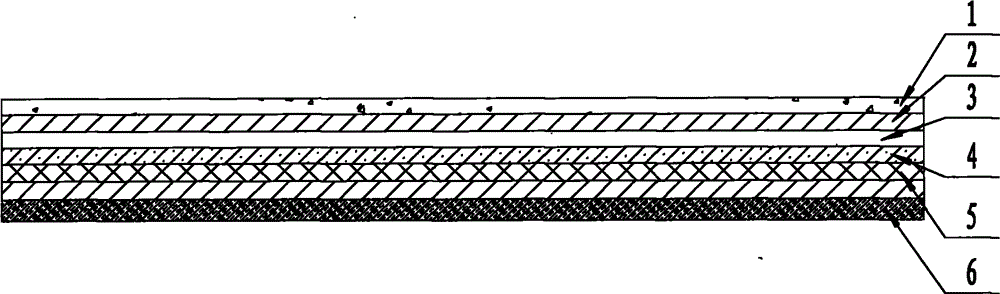

[0011] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 It is a schematic diagram of the structure of the high-barrier low-temperature casing film of the present invention, a high-barrier low-temperature casing film, and the structure of the casing film is TPO film layer, TIE film layer, TGPA film layer, TIE film layer, PA A seven-layer composite structure formed by a film layer, a TIE film layer and a PO film layer; the TPO film layer is a copolymer mixture; the TIE film layer is an adhesive resin layer; the TGPA film layer is a high barrier material ;

[0012] The feature of this embodiment is that the structure of the casing film is a seven-layer composite formed from the outside to the inside by TPO film layer, TIE film layer, TGPA film layer, TIE film layer, PA film layer, TIE film layer and PO film layer. structure. The TPO film layer has comprehensive characteristics such as high tensile strength, good wear re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com