External spiral multipage reverse osmosis membrane

A reverse osmosis membrane, external spiral technology, applied in reverse osmosis, osmosis/dialysis water/sewage treatment, etc., can solve the problems of reducing the total water production of membrane elements, increasing the resistance of hydration water flow, and reducing the utilization rate of membranes. , to achieve the effect of increasing water production, increasing flow rate, and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

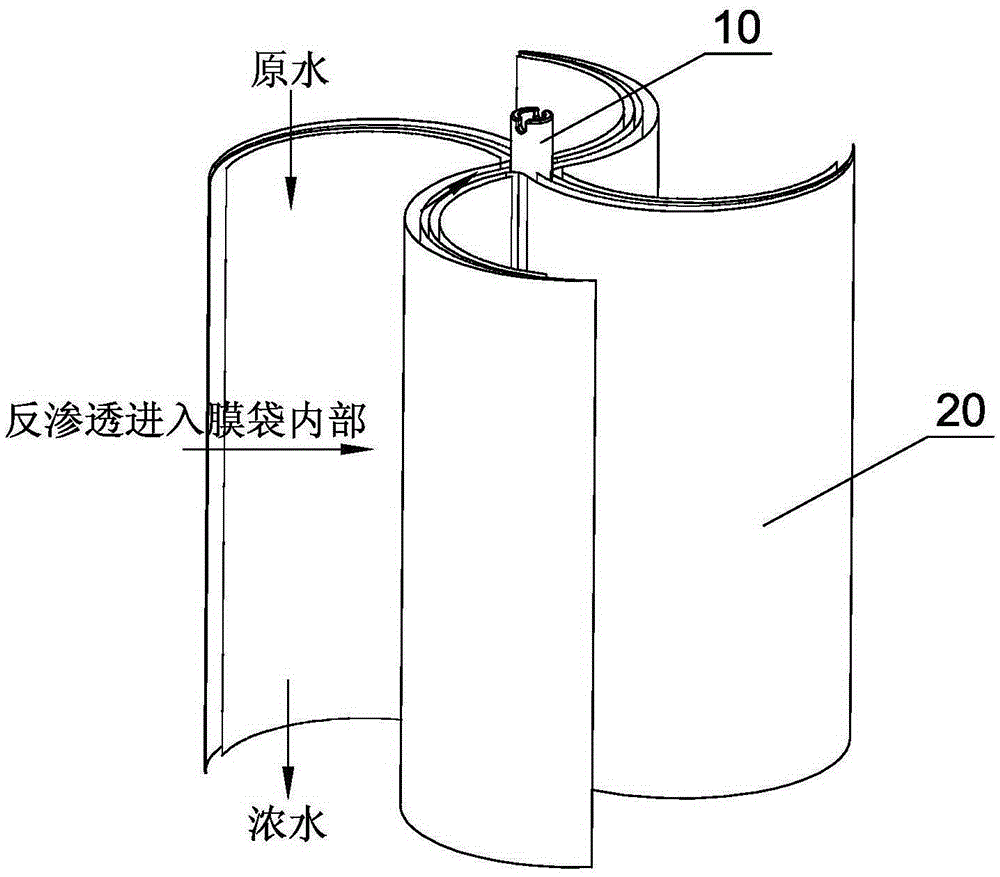

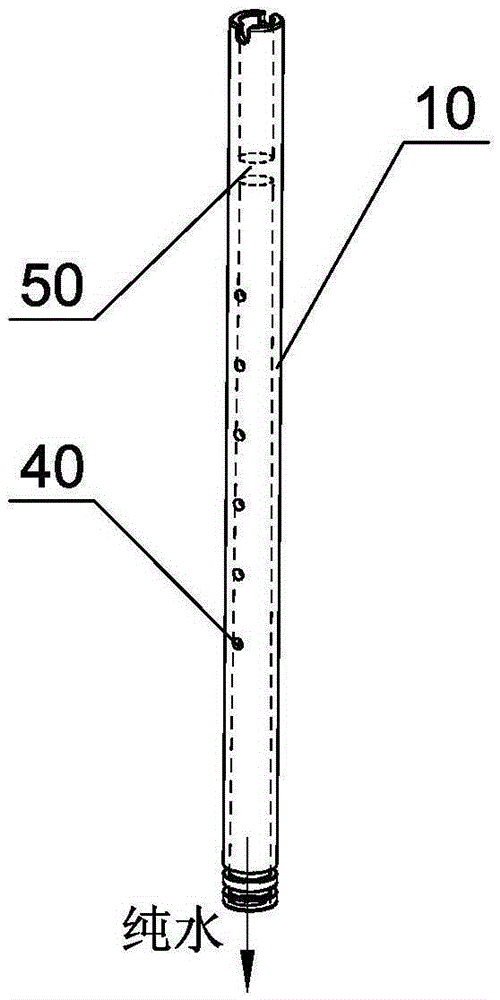

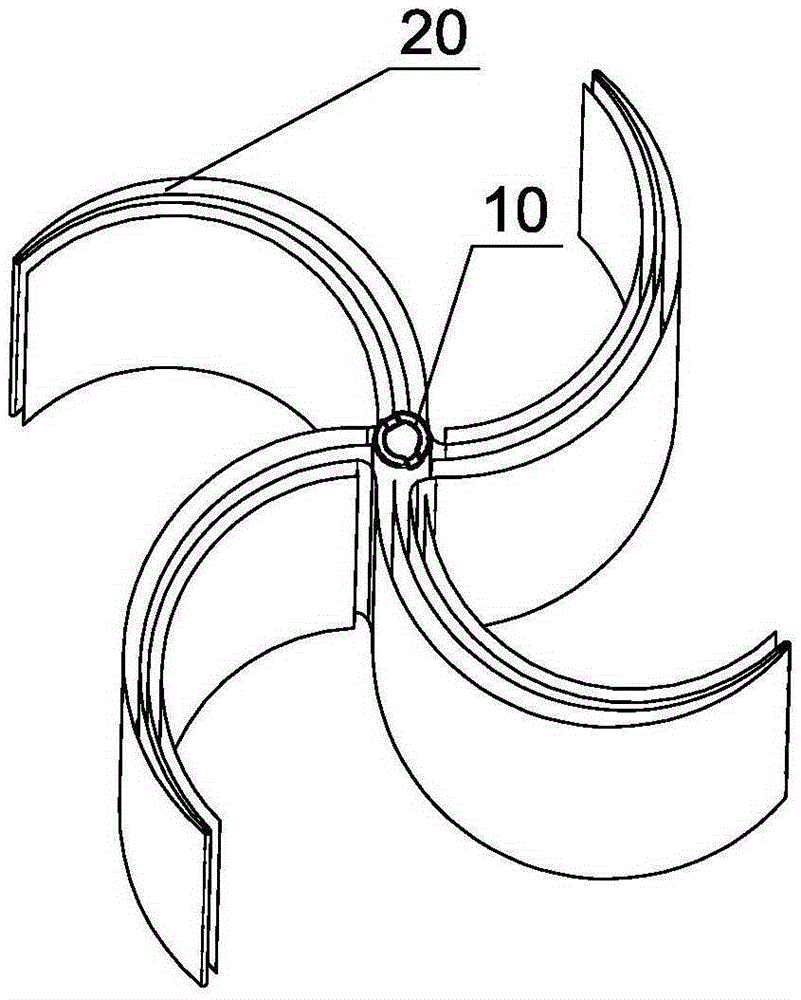

[0017] Such as Figure 4 ~ Figure 7 As shown, the outer spiral multi-sheet reverse osmosis membrane of this embodiment includes a central pipe 1, at least two membrane bags 2, and outer end water collection pipes 3 that are in the same number as the number of the outer end water collection pipes 3. Several water inlets 4 are provided, and the inner end of the membrane bag 2 is fixed on the central tube 1. In this embodiment, one end of the membrane bag 2 and the central tube 1 are fixed by ultrasonic welding or Bonding and fixing, each of the film bags 2 is tightly wound in the same direction along the central tube 1 to form a cylinder composed of multiple layers of film bags, and the outer end of the film bag 2 wraps the outer water collection pipe 3 Inside, raw water enters the membrane bag 2 through reverse osmosis, and is collected into the outer water collection pipe 3 through the water inlet 4, and then pure water is discharged through the end of the outer water collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com