A kind of dummy shaft hydraulic press

A technology of hydraulic press and dummy shaft, which is applied to presses, forging presses, forging presses, etc., can solve the problems of insufficient working range, low working efficiency, and small working stroke, so as to improve the working scope, high working efficiency, and improve working stroke. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

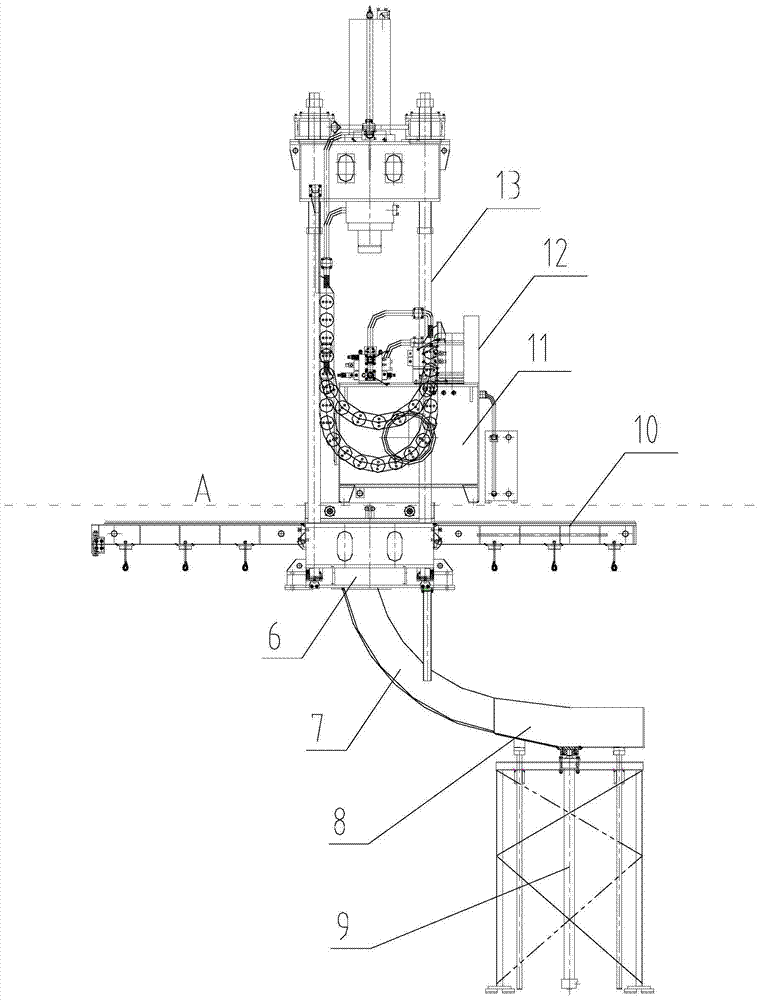

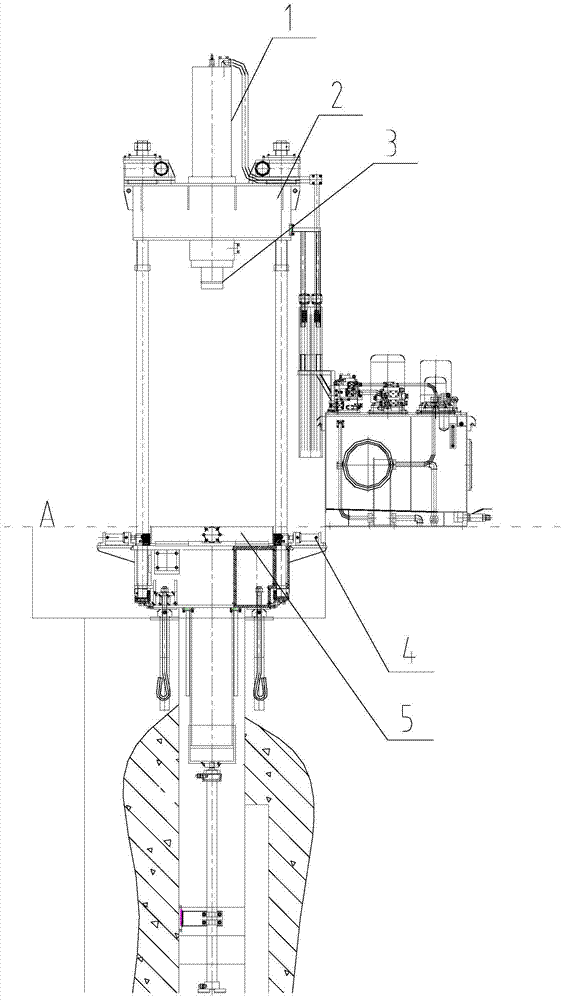

[0021] Such as Figure 1-2 as shown, figure 1 It is a schematic diagram of the front view structure of a hydraulic press for withdrawing false shafts proposed by the present invention; figure 2 It is a side-view structure schematic diagram of a false shaft retraction hydraulic press proposed by the present invention.

[0022] refer to figure 1 and figure 2 , a hydraulic machine for removing false shafts proposed by the present invention, comprising a main oil cylinder 1, a pressure head 3, two mobile trolley positioning mechanisms 4, a slide table type mobile trolley 5, a blanking slideway 7, a hopper 8, a material jacking mechanism 9, Front and rear guide rails 10 of the trolley, hydraulic power system 11, electrical system 12 and frame;

[0023] The frame includes a lower crossbeam 6, a movable upper crossbeam 2 and a pull rod 13, the pull rod 13 is vertically fixed on the lower crossbeam 6, and the movable upper crossbeam 2 is movably installed on the pull rod 13;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com