A kind of equipment and method for extracting refined N2O from tail gas of petrochemical industry

An industrial exhaust and petrochemical technology, applied in the chemical industry, nitrous oxide, climate sustainability, etc., can solve the problems of huge equipment investment, high production cost, low production capacity, etc., to achieve small equipment investment, low production cost, high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

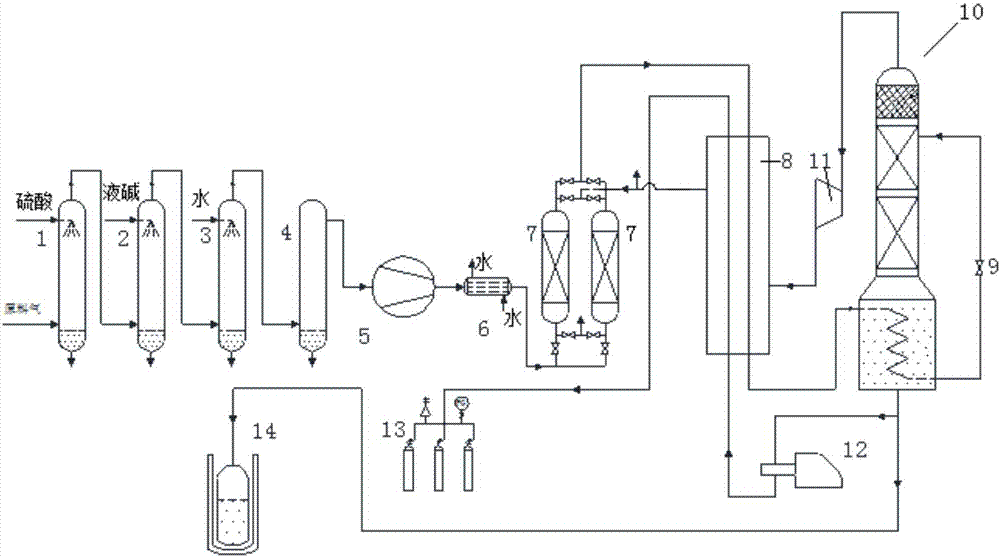

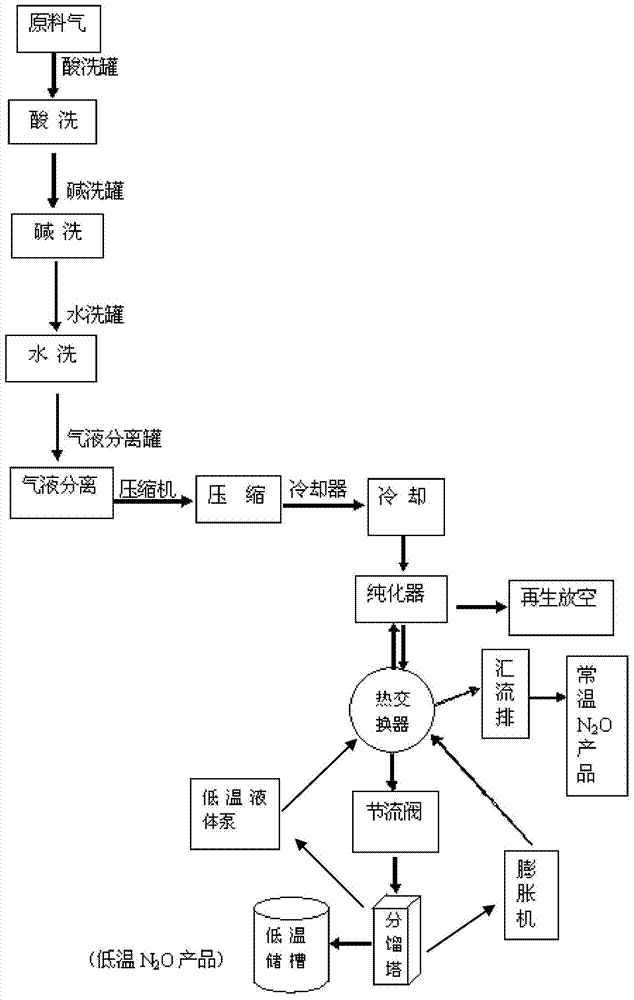

[0041] The invention provides high-purity laughing gas production equipment for liquid crystal (TFT-LCD) manufacture. Extracting refined N from petrochemical industry tail gas in the present invention 2 O's equipment includes chemical purification device, compression cooling device, physical purification device, gas separation device and gas collection device, and they are connected by pipelines in turn. Such as figure 1 Shown, it is extracted refined N from petrochemical industry tail gas in the present invention 2 The equipment structure diagram and process flow diagram of O, as can be seen from the figure, the chemical purification device includes a pickling tower 1, an alkali washing tower 2, a water washing tower 3 and a buffer tank 4, and they are connected in sequence, and an acidic liquid is arranged in the pickling tower 1 , such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com