A water-reducing composite modified starch thickener, its preparation method and application

A composite modification, water-reducing technology, applied in the field of concrete admixtures, can solve the problems of affecting early strength, slow dissolution, limited use, etc., and achieve the effects of low price, good water solubility and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

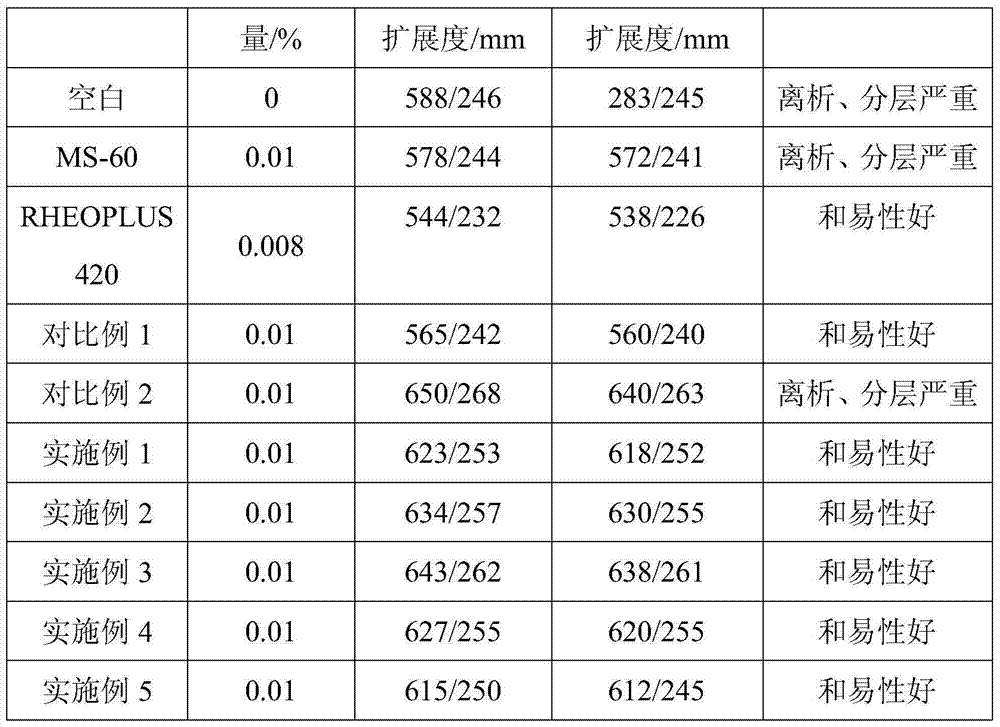

Examples

Embodiment 1

[0033] Put 100 parts of DE=5 maltodextrin in the reaction kettle, add water dissolved in anhydrous sodium sulfate to adjust the concentration of the solution to 40%, dissolve 15 parts of anhydrous sodium sulfate in every 100 parts of water, then add 1.25 parts of sodium hydroxide, Stir at room temperature for 0.5h, blow nitrogen to remove the air, add 17.5 parts of propylene oxide, seal the reaction vessel, place it at 40°C for 18 hours, wash with absolute ethanol after the reaction, and dry to obtain etherified maltodextrin; take 50 parts of ether Prepare maltodextrin with pyridine to a concentration of 40%, add 0.3 parts of sodium hydroxide, stir at room temperature for 0.5 h, then add 20 parts of 1,3-propane sultone, react at room temperature for 8 h, wash with absolute ethanol , filtered, and dried to obtain the sample. Finally, after the product was dissolved in 262 parts of water, the pH was adjusted to 7.2 with 2.4 parts of 1mol / L sodium hydroxide solution, and the soli...

Embodiment 2

[0035] Put 100 parts of DE=2 maltodextrin in the reaction kettle, add water dissolved in anhydrous sodium sulfate to adjust the solution concentration to 40%, dissolve 5 parts of anhydrous sodium sulfate in every 100 parts of water, then add 0.5 parts of sodium hydroxide, Stir at room temperature for 0.5h, blow nitrogen to remove the air, add 10 parts of propylene oxide, seal the reaction vessel, place it at 30°C for 24 hours, wash with absolute ethanol after the reaction, and dry to obtain etherified maltodextrin; take 50 parts of ether Prepare maltodextrin with pyridine to a concentration of 40%, add 0.5 parts of sodium hydroxide, stir at room temperature for 0.5 h, then add 10 parts of 1,3-propane sultone, react at room temperature for 12 h, wash with absolute ethanol , filtered, and dried to obtain the sample. Finally, after dissolving the product in 245 parts of water, adjust the pH to 7.6 with 1.7 parts of 1mol / L sodium hydroxide solution, and the solid content of the pr...

Embodiment 3

[0037] Put 100 parts of DE=8 maltodextrin in the reaction kettle, add water dissolved in anhydrous sodium sulfate to adjust the concentration of the solution to 40%, dissolve 25 parts of anhydrous sodium sulfate in every 100 parts of water, then add 2 parts of sodium hydroxide, Stir at room temperature for 0.5h, blow nitrogen to remove the air, add 25 parts of propylene oxide, seal the reactor, place it at 50°C for 12 hours, wash with absolute ethanol after the reaction, and dry to obtain etherified maltodextrin; take 50 parts of ether Prepare maltodextrin with pyridine to make 40% concentration, add 0.1 part of sodium hydroxide, stir at room temperature for 0.5 h, then add 30 parts of 1,3-propane sultone, react at room temperature for 4 h, wash with absolute ethanol , filtered, and dried to obtain the sample. Finally, after the product was dissolved in 256 parts of water, the pH was adjusted to 7.5 with 4 parts of 1mol / L sodium hydroxide solution, and the solid content of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com