Anti-static and flame-retardant graphene-based polypropylene composite and preparation method thereof

A technology of olefin-based polypropylene and composite materials, which is applied in the field of antistatic and flame-resistant graphene-based polypropylene composite materials and its preparation, can solve the problems of limited popularization, complicated process, and high production cost, and achieve cost reduction and process Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

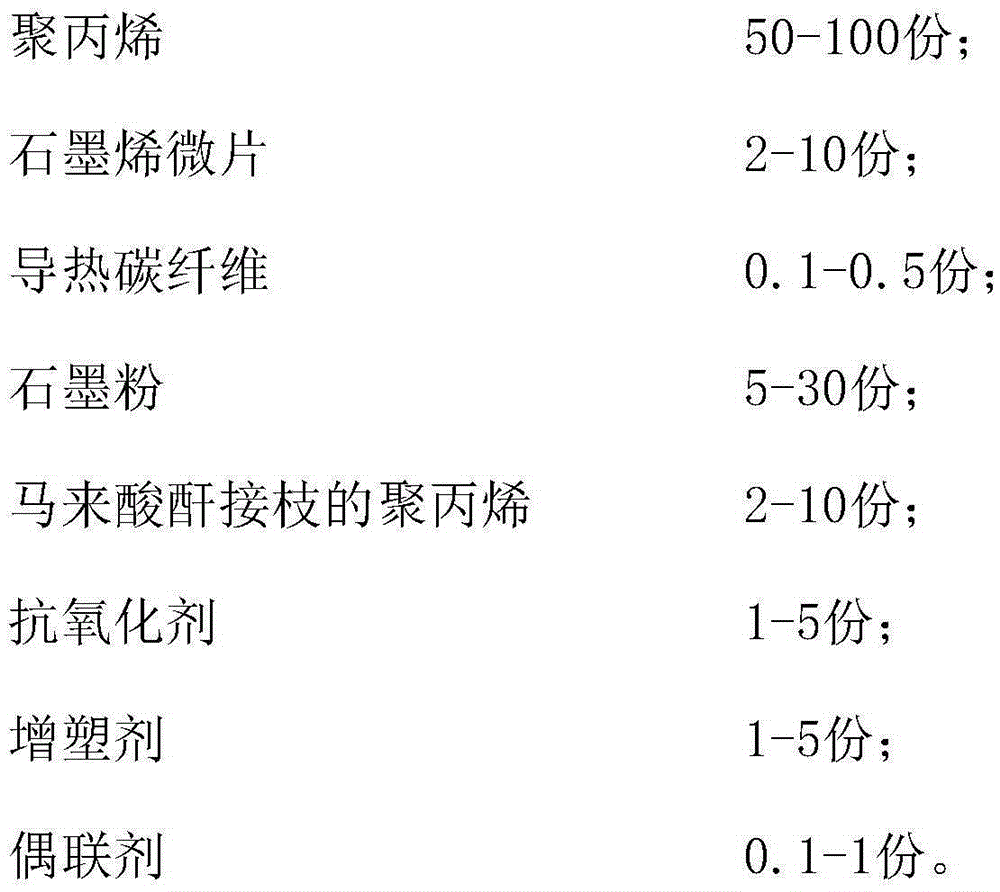

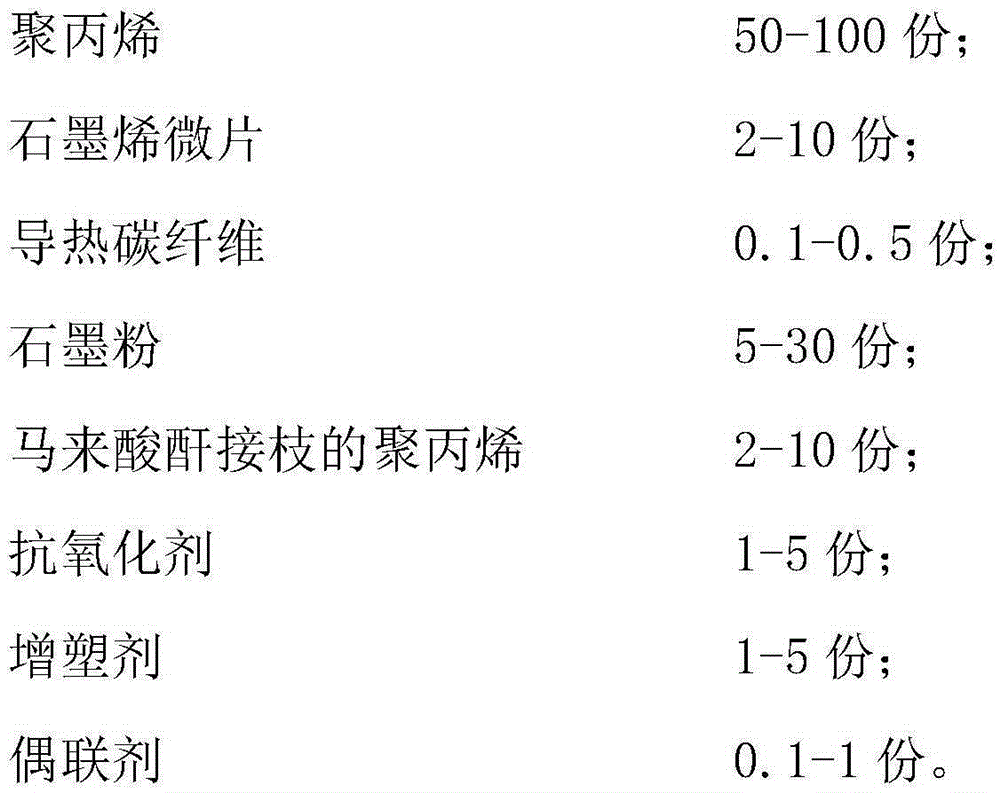

Method used

Image

Examples

Embodiment 1

[0025] Get 2 mass parts of graphene microflakes, 0.5 mass parts of thermally conductive carbon fiber, 5 mass parts of graphite powder, and 2 mass parts of maleic anhydride grafted polypropylene and mix evenly, add 100 mass parts of polypropylene, and mix again , and finally add 2 parts by mass of antioxidant, 2 parts by mass of plasticizer, and 0.5 parts by mass of coupling agent. Next, the above raw materials were dried at 120° C. for 6 hours, sent to a twin-screw extruder for extrusion, and pelletized with a pelletizer. The temperature of each zone of the screw is: zone 1 190°C, zone 2 200°C, zone 3 200°C, zone 4 200°C, zone 5 200°C, head temperature 190°C, screw speed 20rpm.

[0026] The molecular weight of polypropylene is 80,000-100,000. The thickness of the graphene microflakes is 1nm, and the sheet diameter is 25um. The particle size of graphite powder is 2000 mesh. Antioxidants are monophenols. The plasticizer is methyl phthalate. The coupling agent is KH550.

Embodiment 2

[0028] Get 10 parts by mass of graphene microflakes, 0.1 parts by mass of thermally conductive carbon fiber, 30 parts by mass of graphite powder, and 10 parts by mass of polypropylene grafted with maleic anhydride and mix evenly, add 50 parts by mass of polypropylene, and mix evenly again , and finally add 1 mass part of antioxidant, 5 mass parts of plasticizer, and 0.1 mass part of coupling agent. Next, the above raw materials were dried at 150° C. for 10 hours, fed into a twin-screw extruder for extrusion, and pelletized with a pelletizer. The temperature of each zone of the screw is: zone 1 170°C, zone 2 200°C, zone 3 200°C, zone 4 200°C, zone 5 250°C, head temperature 190°C, screw speed 10rpm.

[0029] The molecular weight of polypropylene is one or more of 100,000-150,000 or 150,000-200,000. The thickness of the graphene microflakes is 3nm, and the sheet diameter is 40um. The particle size of graphite powder is a mixture of 3000 mesh and 3500 mesh. The antioxidant is a...

Embodiment 3

[0031] Get 6 mass parts of graphene microflakes, 0.2 mass parts of thermally conductive carbon fiber, 8 mass parts of graphite powder, 6 mass parts of maleic anhydride grafted polypropylene and mix evenly, add 70 mass parts of polypropylene, and mix again , finally add 5 parts by mass of antioxidant, 1 part by mass of plasticizer, and 1 part by mass of coupling agent. Next, the above raw materials were dried at 130° C. for 8 hours, sent to a twin-screw extruder for extrusion, and pelletized with a pelletizer. The temperature of each zone of the screw is: zone 1 190°C, zone 2 200°C, zone 3 200°C, zone 4 200°C, zone 5 200°C, head temperature 190°C, screw speed 40rpm.

[0032] The molecular weight of polypropylene is 150,000-200,000. The thickness of the graphene microflakes is 2nm, and the sheet diameter is 30um. The particle size of graphite powder is 5000 mesh. The antioxidant is a mixture of hydroquinone and thiobisphenol. The plasticizer is a mixture of butyl phthalate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com