Hoop type connecting structure for composite thin-walled circular pipes

A composite material and connection structure technology, applied in flange connection, sleeve/socket connection, pipe/pipe joint/pipe fitting, etc., can solve the problems of increased labor intensity and man-hours, damage to thin-walled round pipes, low connection efficiency, etc. Improve the efficiency and safety of disassembly and assembly, avoid secondary processing, and the effect of simple and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

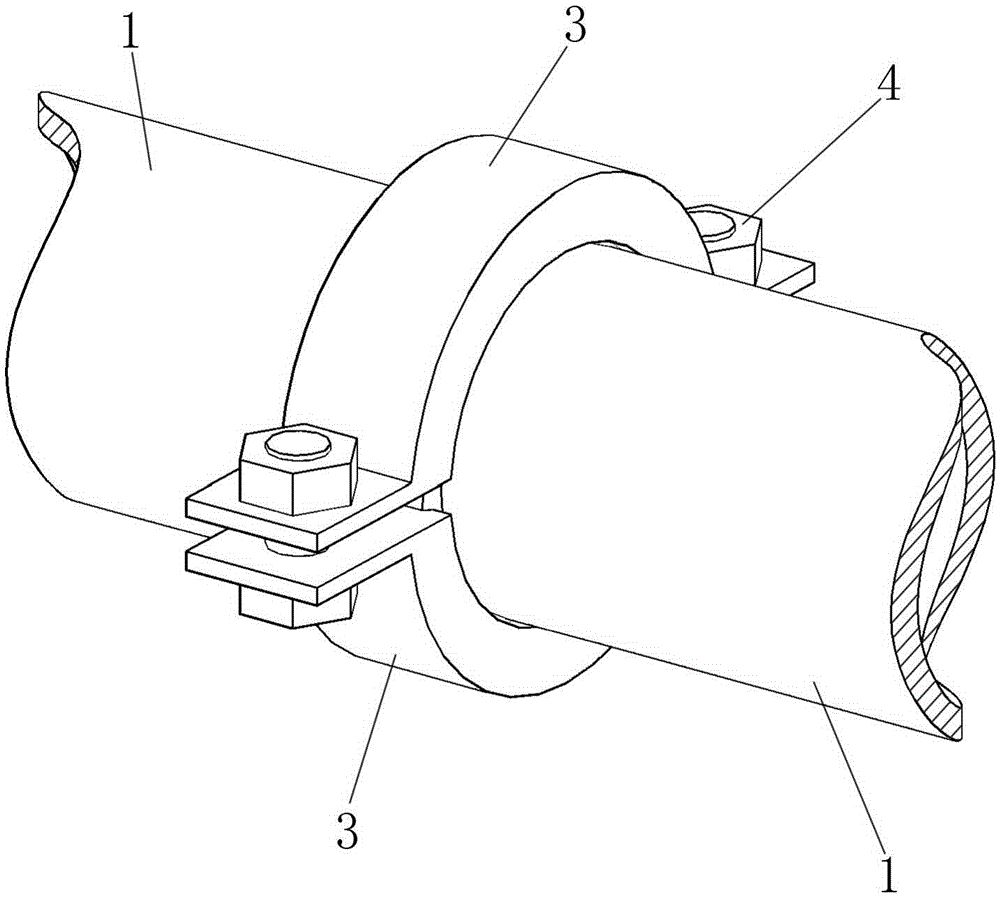

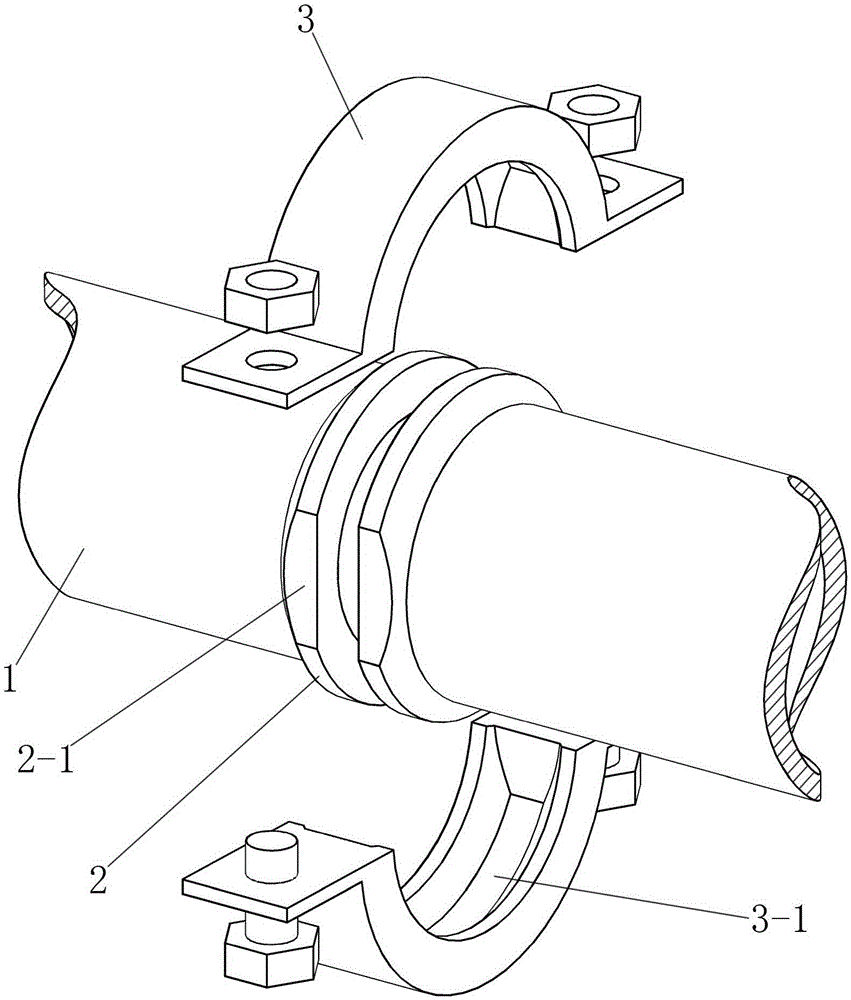

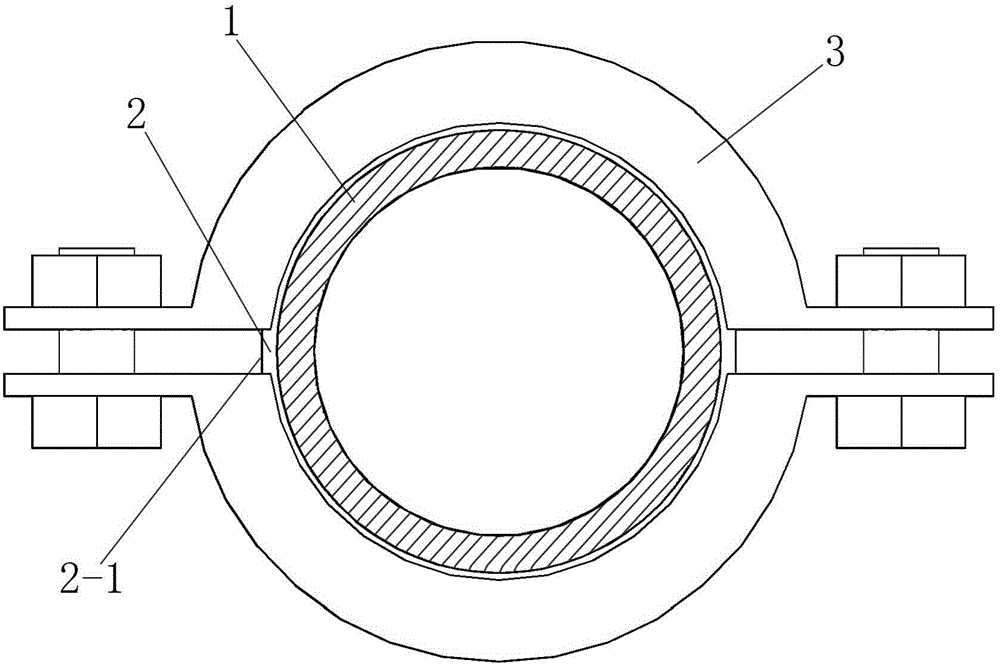

[0023] refer to Figure 1 to Figure 9 , a clamp-type connection structure for composite thin-walled round pipes, which includes two pipes 1 to be connected, and flanges 2 are respectively arranged at the docking ports of the two pipes 1 to be connected, and the two flanges 2 are docked, surrounding the two Each flange 2 is provided with two opposite clamps 3, and the two clamps 3 are connected by two or more than two bolts 4, and the inner sides of the two clamps 3 are provided with clamps that are closely matched with the two flanges 2 Groove 3-1; in ...

specific Embodiment approach 1

[0024] Embodiment 1, the opposite surfaces 2-2 of the two flanges 2 are perpendicular to the axes of the two flanges 2, and the two flanges 2 are gradually thinned from the root 2-3 to the edge 2-4, That is, when the thicknesses of the edges 2-4 of the two flanges 2 are all greater than zero, the cross-sections of the two flanges 2 are all right-angled trapezoids, and the cross-sections of the two flanges 2 are combined into an isosceles trapezoid; when the two flanges When the thickness of the edge 2-4 of 2 is equal to zero, the cross-sections of the two flanges 2 are right-angled triangles, and the cross-sections of the two flanges 2 are combined into an isosceles triangle; correspondingly, the depth of the groove 3-1 is greater than or Equal to the width of the flange 2, the width of the card notch 3-1-1 is less than the total thickness of the roots 2-3 of the two flanges 2, the width of the card slot 3-1 is from the card notch 3-1-1 to the card slot Bottom 3-1-2 tapers (eg...

specific Embodiment approach 2

[0025] Specific embodiment two, there is a special case, the opposite surfaces 2-2 of the two flanges 2 are perpendicular to the axis of the two flanges 2, and the two flanges 2 are from the root 2-3 to the edge 2 -4 becomes thinner, the thickness of the edge 2-4 of the two flanges 2 is equal to zero, that is, the cross-sections of the two flanges 2 are right-angled triangles, the cross-sections of the two flanges 2 are combined into an isosceles triangle, and the slot 3 The width of -1 gradually decreases from the card slot opening 3-1-1 to the card slot bottom 3-1-2, and the bottom width of the card slot 3-1 is zero, that is, the bottom of the card slot 3-1 is a sharp corner, and the card slot The width of the opening 3-1-1 is smaller than the total thickness of the roots 2-3 of the two flanges 2, that is, the cross section of the slot 3-1 is an isosceles triangle, and the cross sections of the two flanges 2 are combined to form an isosceles triangle The inclination angle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com