Coal gangue separation online drying system

A technology of drying system and sorting system, applied in drying, drying machine, drying gas arrangement and other directions, can solve problems such as low efficiency, uneven drying, poor effect of dry sorting device, etc., to ensure stability supply, avoid inefficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

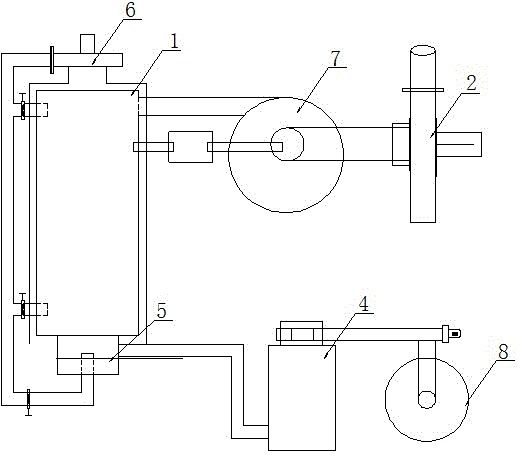

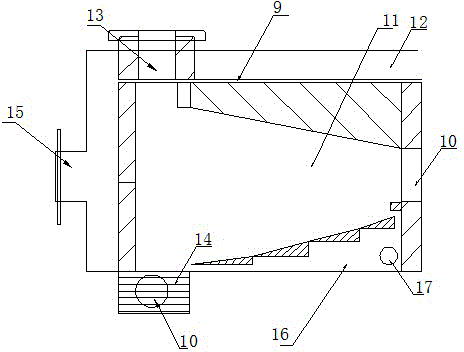

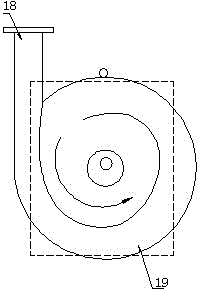

[0026] In order to realize rapid drying of crushed raw coal, reduce land occupation, improve production efficiency, reduce production cost, and especially ensure the normal operation of dry coal preparation, this embodiment provides a figure 1 The coal gangue sorting online drying system shown includes a combustion furnace 1, a main fan 2 of the sorting system connected to the flue gas outlet of the combustion furnace 1 through a pipeline, and a main fan 2 of the sorting system and a composite dry horizontal splitter. The air chamber of the separator is connected, and also includes a clean coal conveyor 3 for transporting clean coal fuel, a multi-stage fan mill 4 for pulverizing the clean coal from the clean coal conveyor 3, and pulverized coal from the multi-stage fan mill 4 The pulverized coal burner that blows into the combustion furnace 1 is in order to realize the rapid drying of the raw coal after crushing, reduce the occupation of land, improve production efficiency, red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com