Geotechnical triaxial test sample radial deformation testing device and method

A technology of radial deformation and triaxial testing, which is applied in the direction of measuring devices, preparation of test samples, and application of stable tension/compression to test the strength of materials, etc., to achieve the effect of simple production, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

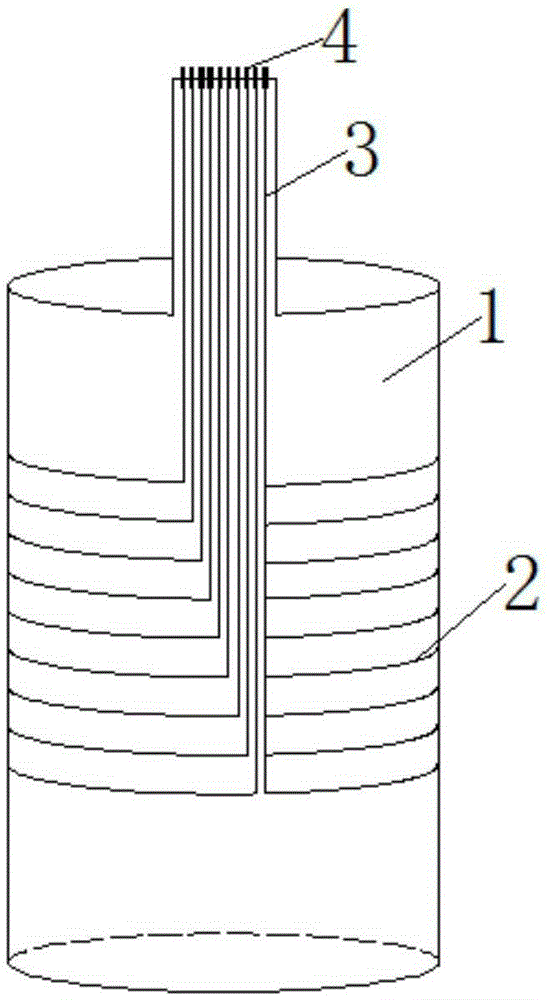

Embodiment 1

[0021] Assuming that the size of the triaxial test sample to be tested is a standard cylindrical sample of φ39.1mm×80mm, make a latex film 1 matching the cylindrical sample, and print an array of sensitive materials on the latex film 1 2 and the conductive electrode array 3, the printed sensitive material array 2 is set to 20 rows, the number of phases and rows of the conductive electrode array 3 connected to it is the same, and terminals 4 are connected to the ends of all the conductive electrode arrays 3. At the beginning of the test, first put the sample to be tested into the latex film 1 of the test device. When installing, ensure that the center position of the sensitive material array 2 coincides with the center position in the height direction of the sample. Install the sample into the test device, use the wire connection terminal 4 to connect the test device with the signal acquisition test instrument, apply pressure to the sample according to the geotechnical triaxial ...

Embodiment 2

[0024] Suppose the size of the triaxial test sample to be tested is a standard cylindrical sample of φ50mm×100mm, and the sensitive material array 2 and the conductive electrode array 3 are printed on the supporting latex film 1 respectively, and the sensitive material array 2 has 30 rows The conductive electrode array 3 connected to the sensitive material array 2 is also 30 rows, and the terminal 4 is connected to the end of the conductive electrode array 3 in the 30 rows. At the beginning of the test, first put the sample to be tested into the latex film 1 of the test device. When installing, ensure that the center position of the sensitive material array 2 coincides with the center position in the height direction of the sample, and then insert the test sample according to the conventional test method. A cylindrical sample of the device is installed in the test apparatus. Connect the test device with the external test instrument by using the wire connecting terminal 4 . Tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com