Electrical test head used for keyboard key electrical performance testing

An electrical performance testing and testing head technology, applied in the field of testing institutions and electrical testing testing heads, can solve problems such as inconvenience of maintenance, and achieve the effects of accurate and efficient testing, fast adjustment of the whole machine, and smooth adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

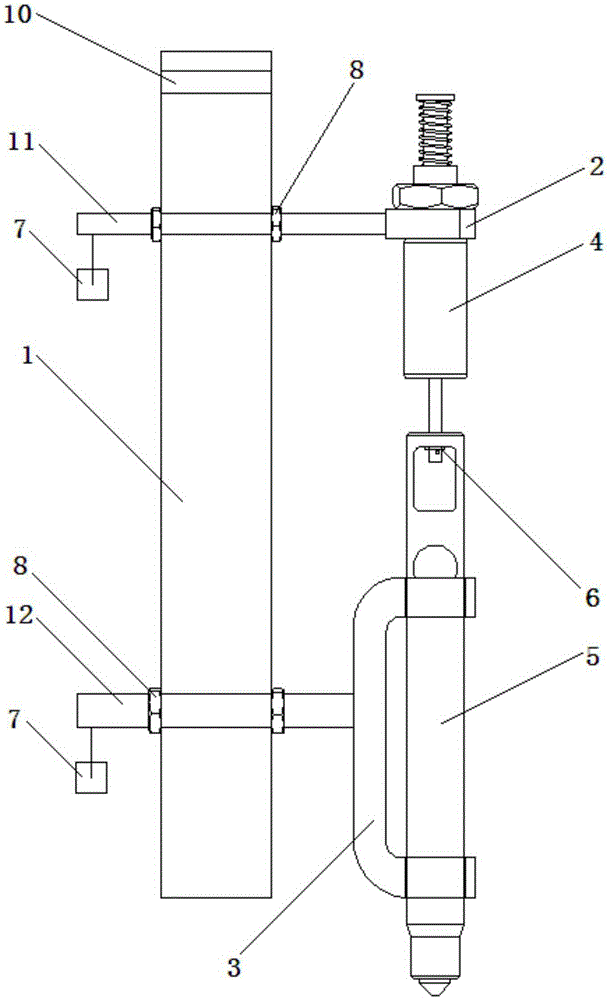

[0022] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0023] Such as figure 1 The shown electrical test head for testing the electrical performance of keyboard keys includes a vertically distributed fixing frame 1, vertically penetrates and locks the first crossbar 11 and the second crossbar 12 of the fixing frame 1, and installs them respectively. The fixed ring 2 and the limit ring 3 at the same side end of the first cross bar 11 and the second cross bar 12, and the test head assembly installed on the fixed ring 1; the first cross bar 11 and the second cross bar 12 Distributed in a straight line from top to bottom, the test head assembly includes electromagnets 4 and weights 5 connected in an overlapping manner from top to bottom.

[0024] Described electromagnet 4 is fixed on fixed ring 2, and the top of electromagnet 4 is free end, is used for being connected with test wire, and the bottom end sleeve of el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com