Integrated high-return-loss optical component adapter

An adapter and high return loss technology, applied in optical components, light guides, optics, etc., can solve the problems of affecting the quality of transmission signals, reducing the signal-to-noise ratio of communication, and increasing processing costs, so as to improve optical performance and optical return loss , the general effect of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

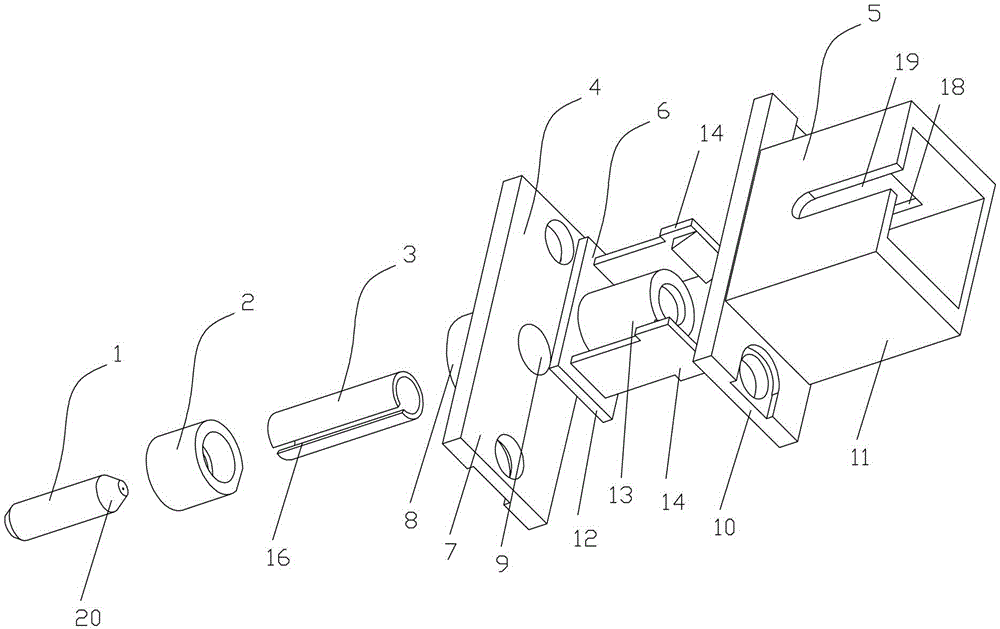

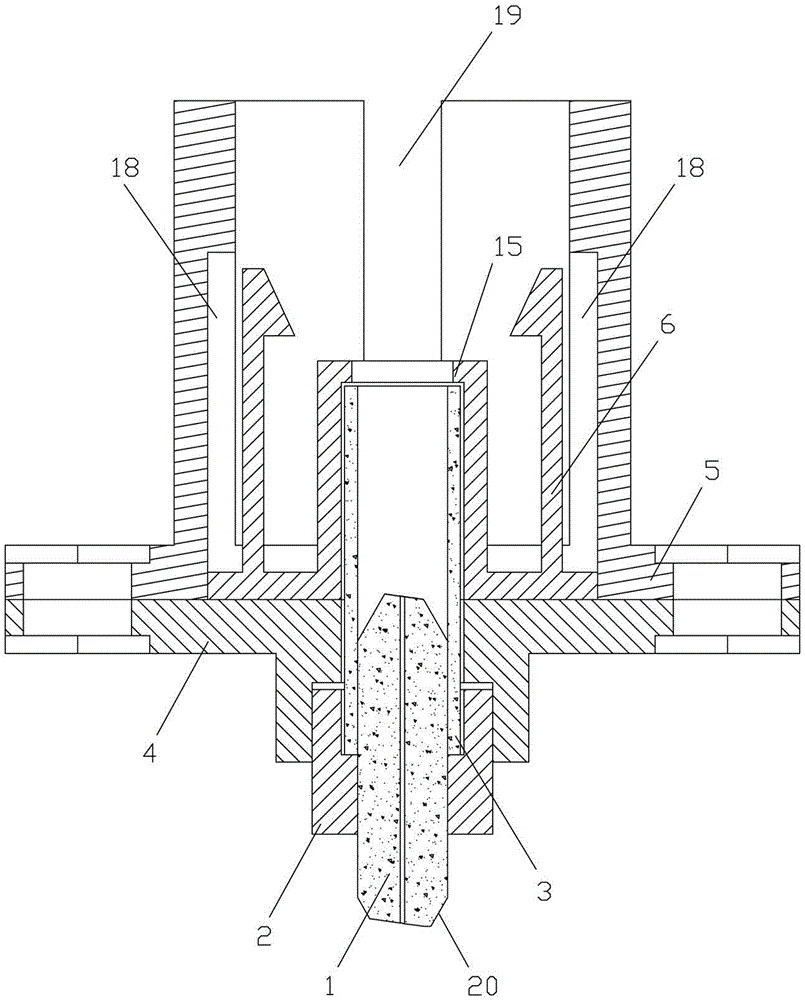

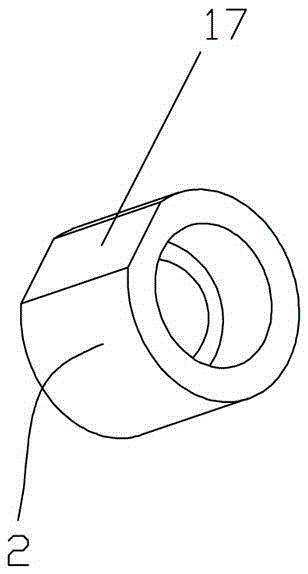

[0018] see Figure 1-3 , the present invention includes plug-in adapter parts, ceramic ferrule 1, positioning metal ring 2 and ceramic sleeve 3, plug-in adapter parts include front and rear seats 4, 5 and card holder 6, and front seat 4 has The bottom plate A7 and the protruding structure 8 arranged on the end surface of the bottom plate A7 and the stepped through hole 9 passing through the bottom plate A7 and the protruding structure 8, and the aperture of the through hole on the protruding structure 8 is larger than the aperture of the through hole on the bottom plate A7 , the rear seat 5 has a bottom plate B10, and a cylindrical shell 11 is arranged on the end surface of the bottom plate B10, wherein the bottom plate A7 matches the bottom plate B10 and is fastened and connected by bolts; 5 Pressed on the bottom plate A7 (there is a groove on the end surface of the bottom plate B10 that fits the bottom plate A7, and the groove matches the bottom plate C12), and a limit sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com