Battery box for electric vehicle

A technology for electric vehicles and battery boxes, which is applied to secondary batteries, battery pack components, secondary battery repair/maintenance, etc. It can solve problems such as not being able to be placed inside the battery box, taking up space outside the car, and large volume of the equalization system , to achieve the effect of ensuring capacity and service life, reducing space occupation, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

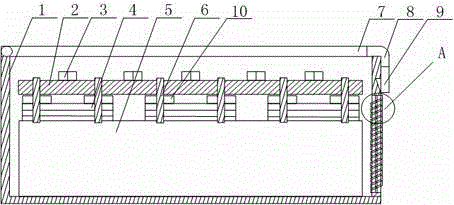

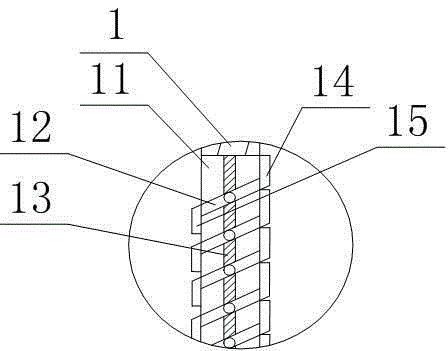

[0020] Such as figure 1 and figure 2 As shown, this embodiment includes a box body 1 with an open upper end and a cover body 7 hingedly fitted with it. At the end of the cover body 7, a buckle 9 is installed through an elastic connector 8. The side of the box body 1 There is a card slot on the wall to cooperate with the buckle 9, the battery pack 5 is fixed in the box body 1, a balancing system is installed on the battery pack 5, and on the side wall of the box body 1 on the same side as the slot A through hole 11 is opened, and support plates 13 are respectively installed on the two side walls of the through hole 11. A plurality of swing plates 12 are arranged side by side up and down and rotated on the two support plates 13. The swing plates 12 are close to the inner wall of the box 1. The weight of one end is greater than the weight of the end near the outer wall of the box body 1 to make the swing plate 12 oblique, and the left wing plate 15 and the right wing plate 14 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com