A kind of activated carbon material and preparation method for cathodic reaction

A cathode reaction and activated carbon technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor performance of activated carbon-based catalysts, complicated preparation methods, and inability to be widely used in practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

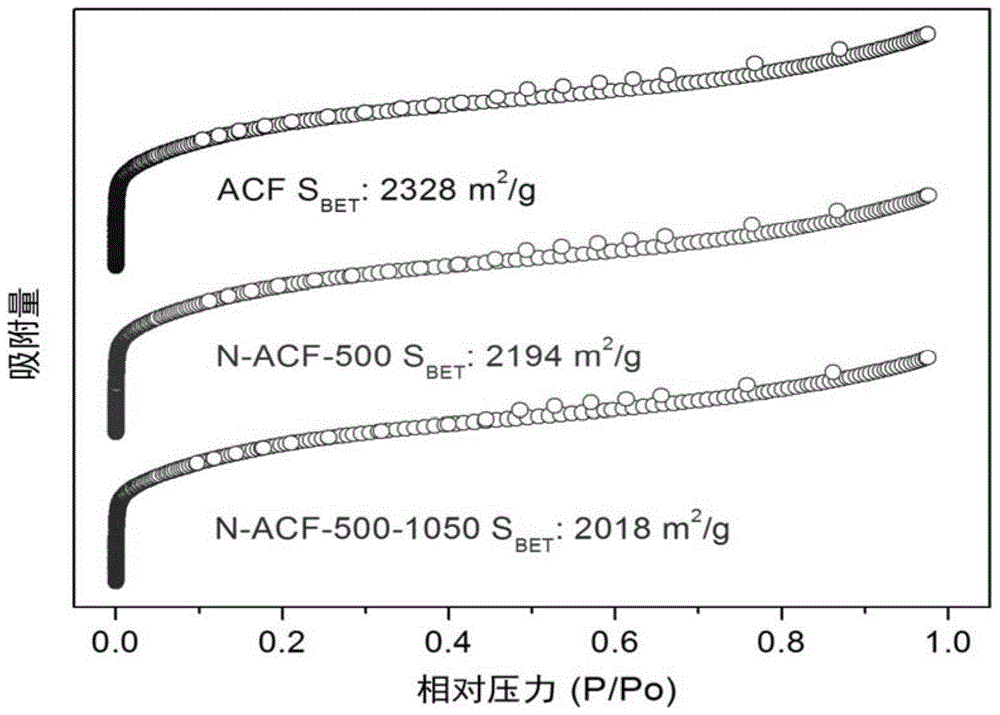

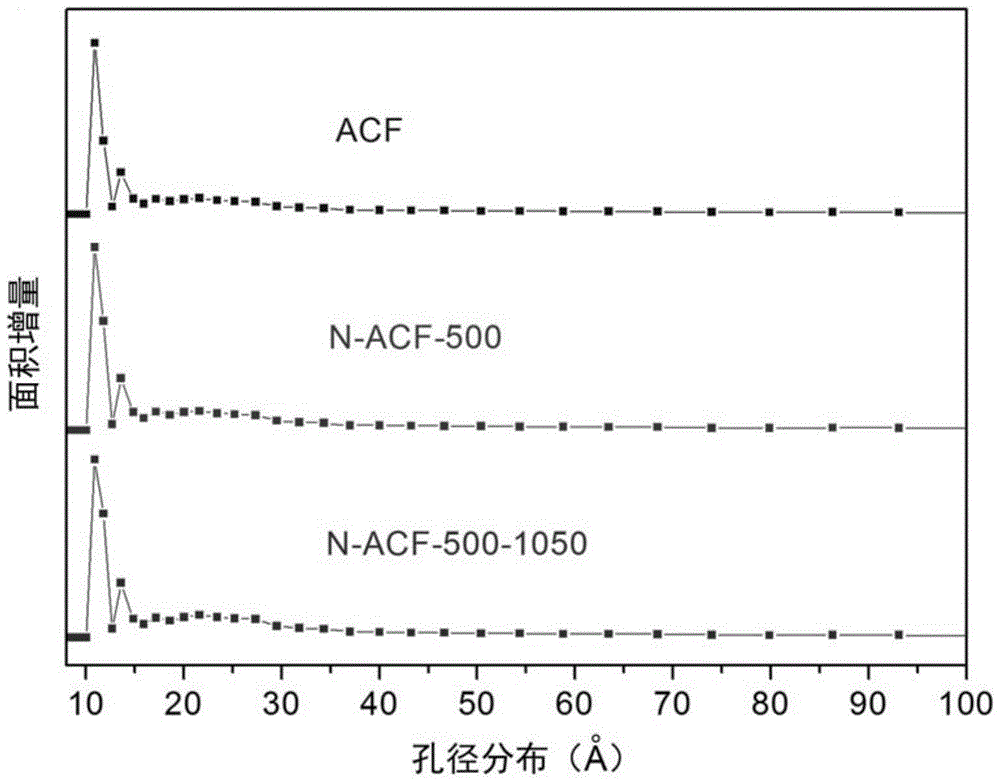

[0031] In addition, the embodiment of the present invention also provides a method for preparing an activated carbon material used for the cathode reaction of fuel cells and metal-air batteries, which mainly includes the following steps:

[0032]S01, activated carbon is activated to obtain a product one;

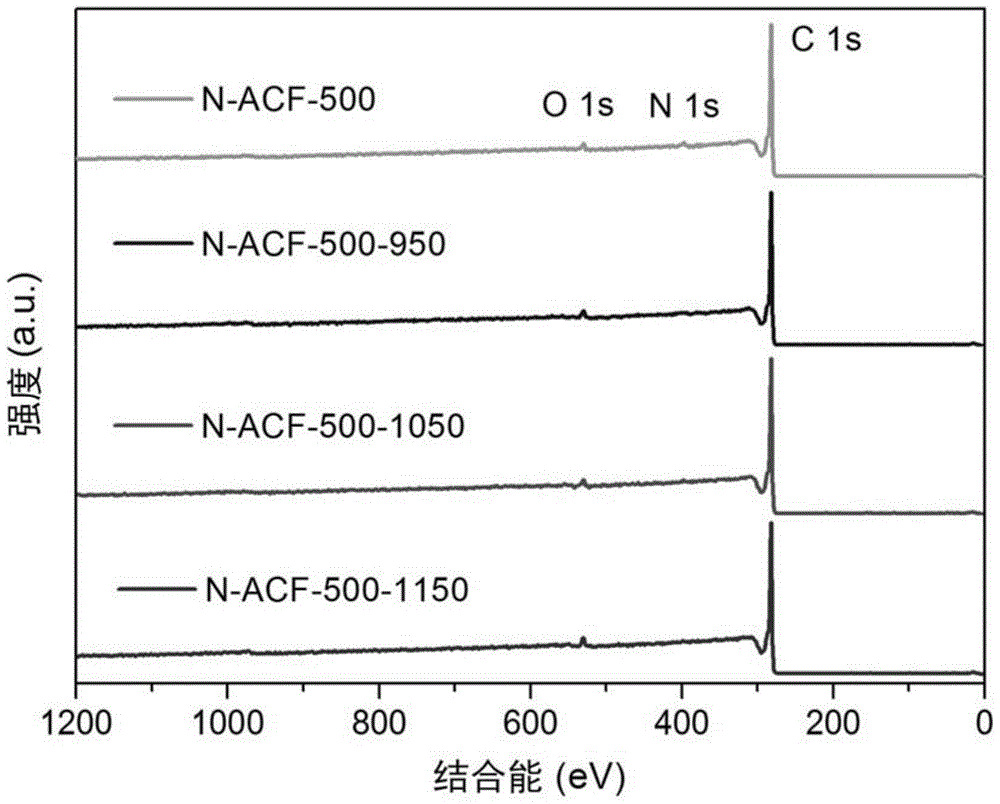

[0033] S02. The product one is placed in an ammonia atmosphere, and calcined at a temperature of 400-900° C. for 1-5 hours to perform nitrogen doping treatment to obtain product two;

[0034] S03. The product 2 is placed in an inert gas atmosphere, and calcined at a temperature of 850-1150° C. for 1-5 hours for denitrification treatment to obtain a defective activated carbon material.

[0035] Specifically, the above S01 step can be completed by using the existing activated carbon activation treatment method. Preferably, the activated carbon and the activator can be mixed in a mass ratio of 1:3-1:10, and then the mixture is placed in an inert gas atmosphere at 500-900 ° C. ...

Embodiment 1

[0040] (1) Activated carbon and potassium hydroxide were physically mixed in an alumina porcelain boat at a mass ratio of 1:7.5, and then placed in a tube furnace. First purging with nitrogen for 30 minutes, and then run the temperature rise program: from room temperature to 750°C at a rate of 5°C / min, then keep the temperature at 750°C for 60 minutes under a nitrogen atmosphere, end the program, and cool down with the furnace;

[0041] (2) Dissolve the sample obtained in step (1) with deionized water first, then add an excess of 3mol / L hydrochloric acid to wash, and finally use deionized water to filter and wash the solution to neutrality, then dry it at 80°C Dry in the box for 12 hours;

[0042] (3) Treat the activated carbon obtained in step (2) under an ammonia atmosphere at 500°C for 3h (the heating rate is 3°C / min) to obtain a nitrogen-doped sample;

[0043] (4) The activated carbon obtained in step (3) was further calcined for 2 h at 950 °C under a nitrogen atmosphere ...

Embodiment 2

[0045] (1) Activated carbon and potassium hydroxide were physically mixed in an alumina porcelain boat at a mass ratio of 1:7.5, and then placed in a tube furnace. First purging with nitrogen for 30 minutes, and then run the temperature rise program: from room temperature to 750°C at a rate of 5°C / min, then keep the temperature at 750°C for 60 minutes under a nitrogen atmosphere, end the program, and cool down with the furnace;

[0046] (2) Dissolve the sample obtained in step (1) with deionized water first, then add an excess of 3mol / L hydrochloric acid to wash, and finally use deionized water to filter and wash the solution to neutrality, then dry it at 80°C Dry in the box for 12 hours;

[0047] (3) Treat the activated carbon obtained in step (2) under an ammonia atmosphere at 500°C for 3h (the heating rate is 3°C / min) to obtain a nitrogen-doped sample;

[0048] (4) The activated carbon obtained in step (3) was further calcined for 2 h at 1050° C. under a nitrogen atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com