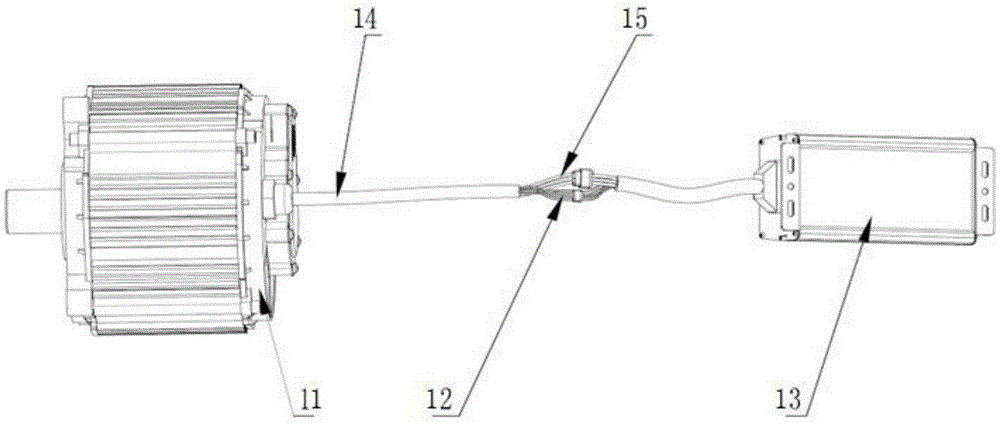

Control structure of motor with built-in control system

A technology of control structure and control system, applied in the direction of structural connection, electric components, electrical components, etc., can solve the problems of high failure rate, increased line loss and system cost, inconvenient installation, etc., to reduce the failure rate, save labor costs, Loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

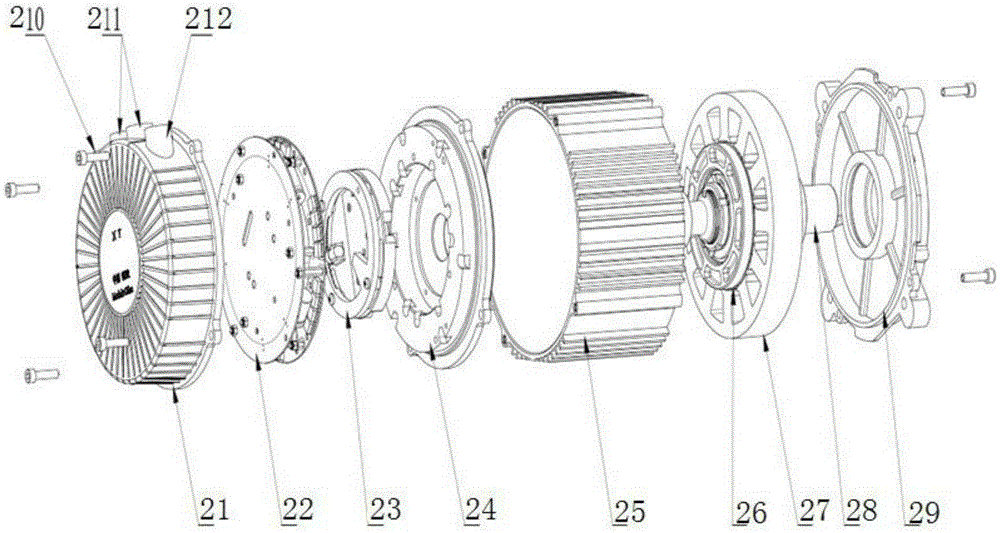

[0025] Such as figure 2 As shown, a control structure of a motor with a built-in control system includes a shield 21, a casing 25, a rotor 26, a stator 27 and a main shaft 28; it is characterized in that it includes a motor control system; the structure of the motor body breaks through the structure of conventional motors Design structure, from one side of the motor to the other side is the shield 21, the control system 22, the rear end cover 24, and the casing 25; the casing includes the rotor 26, the stator 27 and the main shaft 28; The rear end cover 24 of the motor is not only a component of the electrode, but also a fixed part of the control system. For the motor, the rear end cover 24 and the front end cover 29 are jointly used to support the bearing 28; The role of heat dissipation.

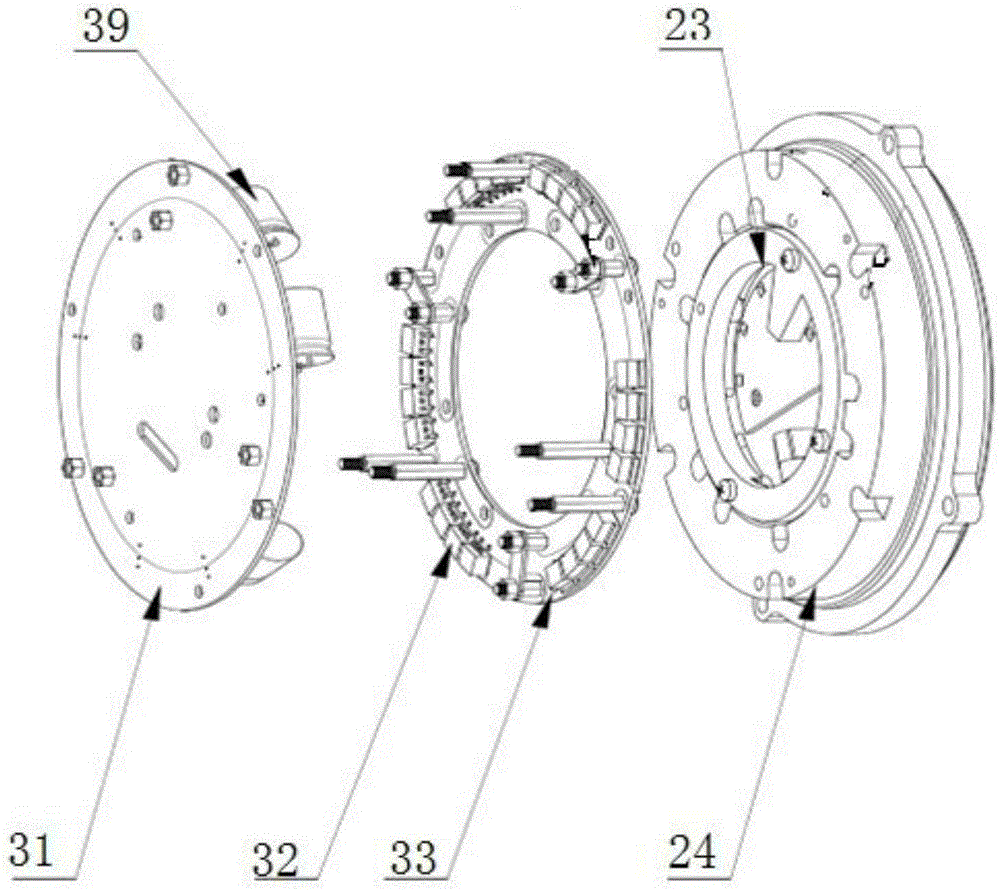

[0026] Such as image 3 As shown, the motor control system 22 is installed outside the rear end cover 24 of the motor; it includes a control board 31 , a power drive board 33 and a Hall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com