Piezoelectric driven rapid cooling device

A heat dissipation device and piezoelectric drive technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of unfavorable protection of electronic chips, discount of heat dissipation, etc., and achieve the effects of accelerated flow speed, controllable vibration speed, and accelerated heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

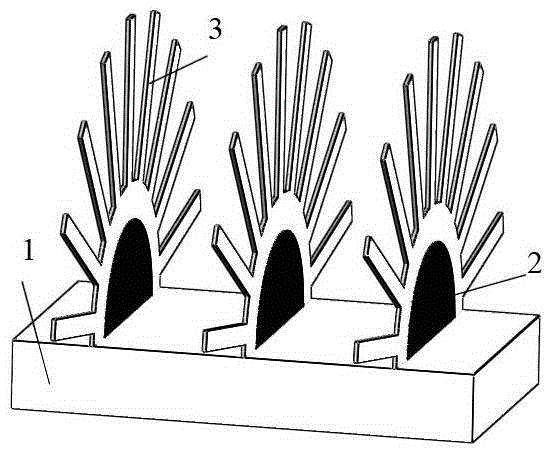

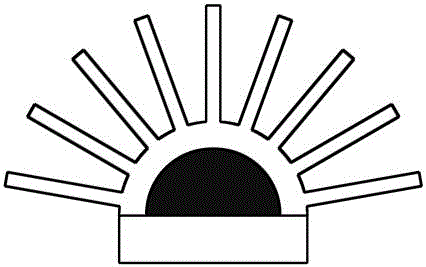

[0020] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings:

[0021] Such as figure 1 with figure 2 As shown, the present invention discloses a piezoelectric-driven rapid heat dissipation device, which includes a base and a number of flexible heat sinks arranged on the base;

[0022] Both the base and the flexible heat sink are made of thermally conductive materials;

[0023] The flexible heat sink is in the shape of a thin sheet and is prone to vibration and bending, and includes a vibration unit and a plurality of strip heat dissipation units arranged on the vibration part;

[0024] The vibration unit is fixed on the base, and the surface is provided with a piezoelectric layer made of piezoelectric material;

[0025] The piezoelectric layer is insulated from the vibrating unit, and is used to drive the vibrating unit to vibrate when alternating current is connected to both sides of the piezoelectric la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com