Transfusion medicine preparing equipment

A device and drug technology, applied in the field of infusion drug preparation equipment, can solve the problems of long waiting time, low drug dispensing speed, and non-crossover, and achieve the effects of convenient transfer, convenient transportation, and simplified internal mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

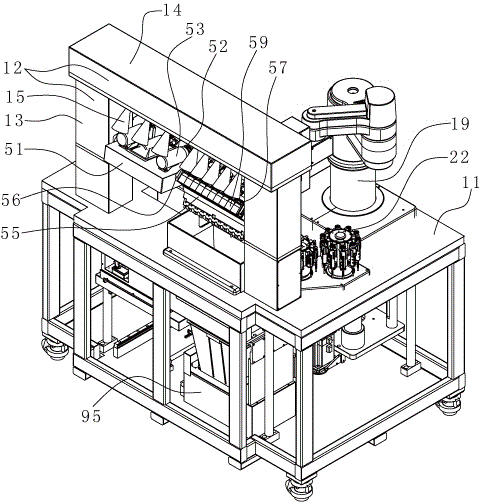

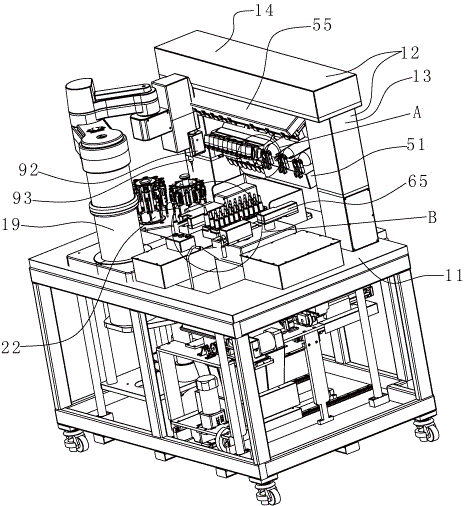

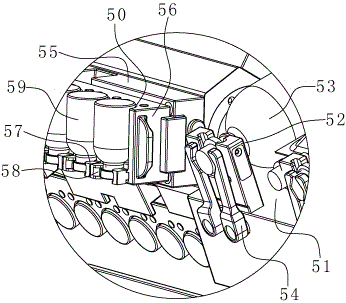

[0024] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an infusion drug preparation device of the present invention includes a base 11, a casing 10 arranged around and above the base 11, fixedly connected to the upper side of the front part of the base 11 and located in the casing The portal frame 12, both ends of which are connected to the horizontal shafts (not shown) of the columns 13 on both sides of the portal frame 12, are respectively rotatably sleeved on one section of the horizontal shaft and locked to the mother liquid bottle holder at a selected angle 51 and powder bottle rack 55, a plurality of mother liquid bottle clamp grooves 52 arranged side by side on the mother liquid bottle rack 51 along the axial direction of the transverse axis, at least one powder bottle tray detachably mounted on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com