Long-acting leuprorelin acetate microsphere and preparation method thereof

A technology of leuprolide acetate and microspheres, which is applied in directions such as medical preparations without active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

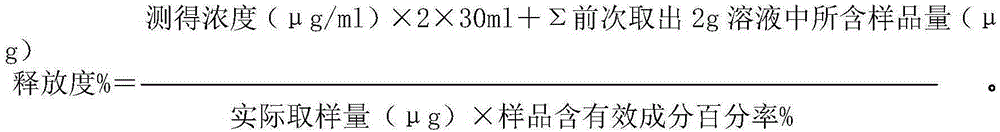

[0048] Experimental example 1: 90-day release study of 8 samples

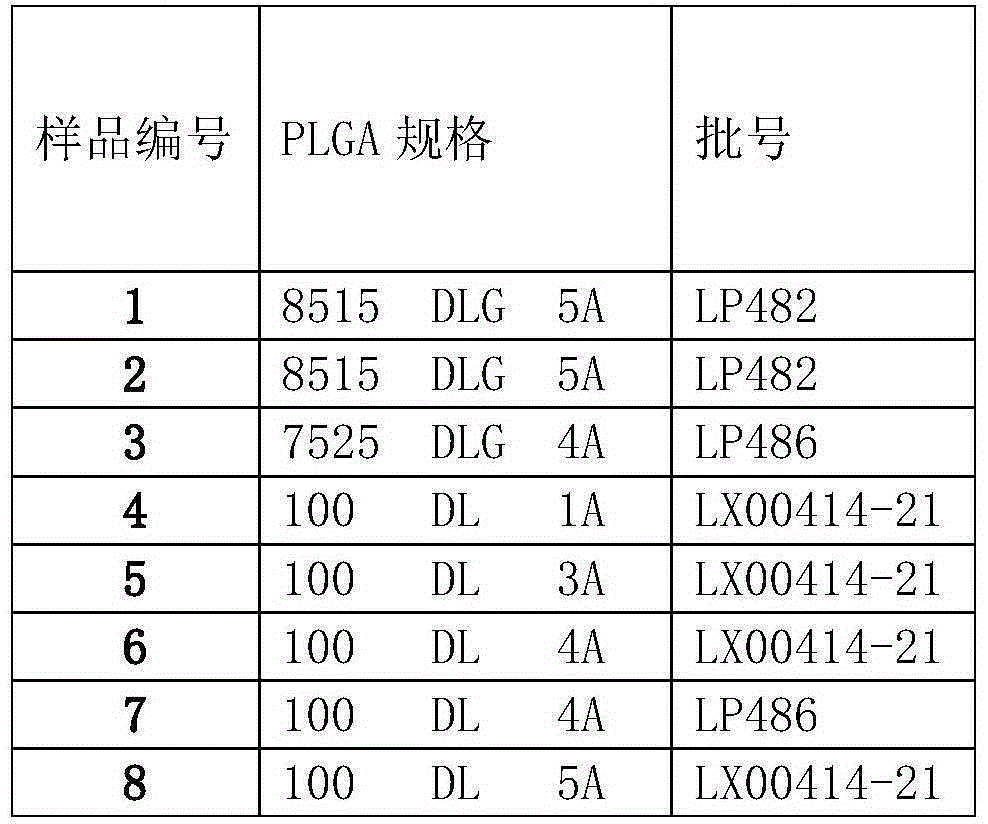

[0049] In this method, 8 samples were prepared using the preparation method in Example 1, and different PLGA models were selected, and the drug loading and in vitro release rate of the microspheres were determined. PLGA is the key factor affecting the release rate. Long-term release requires a larger molecular weight and viscosity to achieve a better effect. This experiment mainly investigates the effect of different PLGA on the release rate. Its molecular weight is 20000-100000, intrinsic viscosity: 20-80g / ml.

[0050] Table 1: Experimental design of different models of PLGA

[0051]

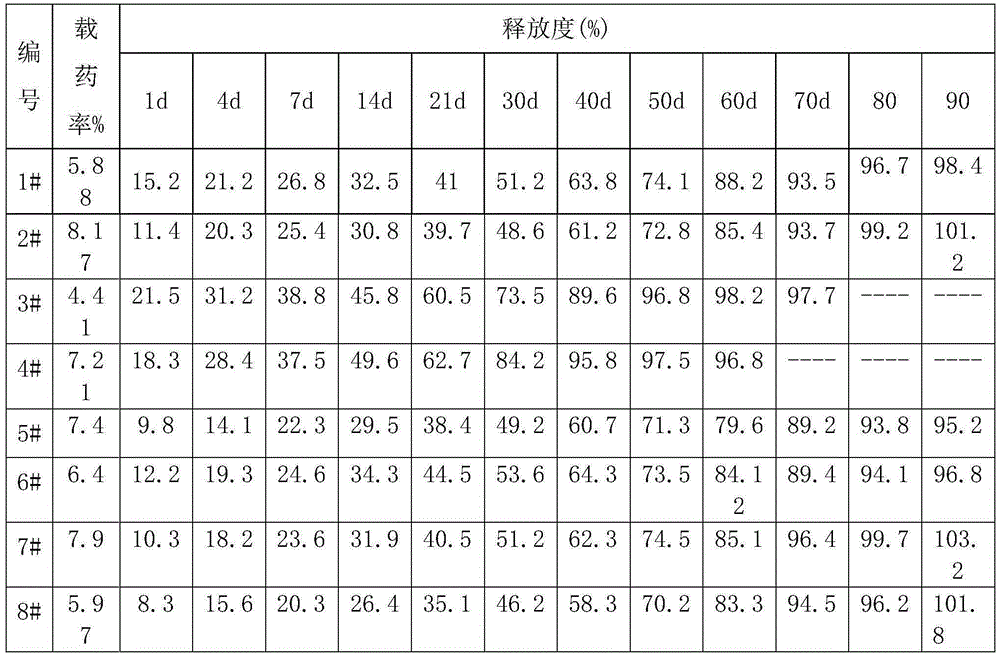

[0052] Table 2: The release rate of each sample at each time point

[0053]

[0054] in conclusion:

[0055] 1. PLGA model 85155A, DL1A, DL4A, and DL5A microsphere release rate can meet the three-month release requirement, but PLGA75254A does not meet the requirement, especially 100DL4A, 5A is better, and the molecular ...

experiment example 2

[0056] Experimental example 2 investigates the impact of raw material and auxiliary material proportioning on yield

[0057] In this experiment, 4 groups of samples were prepared according to the method of Example 1. The difference between each group of samples was that the ratios of raw materials and auxiliary materials PLGA were respectively set (see Table 3 below). This experiment mainly investigated the ratio changes of raw materials and auxiliary materials PLGA.

[0058] Table 3 Experimental results:

[0059]

[0060] Summary: When the ratio is 11.25:85, the yield is the best, and the prepared microspheres can be released for three months, meeting the requirements.

experiment example 3

[0061] Experimental Example 3: Investigate the effect of PLGA concentration on release rate

[0062] In this experiment, three groups of samples were prepared by the method of Example 1. The only difference between each group of samples was that different concentrations of PLGA were set respectively. This experiment mainly investigated the influence of the concentration of PLGA on the yield of microspheres. (See Table 4)

[0063] Table 4: Experimental results

[0064] PLGA concentration

yield

Release

25%

52%

released for three months,

20%

64%

free for three months

15%

54%

Can be released for three months, slightly faster

[0065] Summarize:

[0066] 1. The concentration of PLGA has a certain influence on the yield of microspheres. The concentration of 20% is the best. The viscosity of 25% concentration is too high, which affects the yield. The concentration of 15% is too thin, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com