Chemical adsorption-based gas phase mercury removal method and special-purpose apparatus

A special device and chemical adsorption technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve sensitive and difficult to remove mercury and other problems, and achieve reduced production costs, high reliability, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the gas-phase mercury removal method based on chemical adsorption is carried out according to the following steps: the raw material gas is first cooled to 35 degrees Celsius to 55 degrees Celsius, and then the cooled raw material gas enters the separatory tank 3 for gas-liquid separation to obtain mercury-containing mercury. Sewage and mercury-containing gas, the mercury-containing gas is sent to the drying filter 4 for dry filtration, and the mercury-containing gas after drying and filtering is heated to 45 degrees Celsius to 60 degrees Celsius when the pressure of the mercury-containing gas is greater than 30 kPa. Mercury-containing non-condensable gas, the mercury-containing non-condensable gas is sent into the adsorption tower 5, and the mercury-containing non-condensable gas reacts with the adsorbent in the adsorption tower 5 to remove mercury to obtain mercury-removed non-condensable gas. The present invention still adopts the chemical adsorption meth...

Embodiment 2

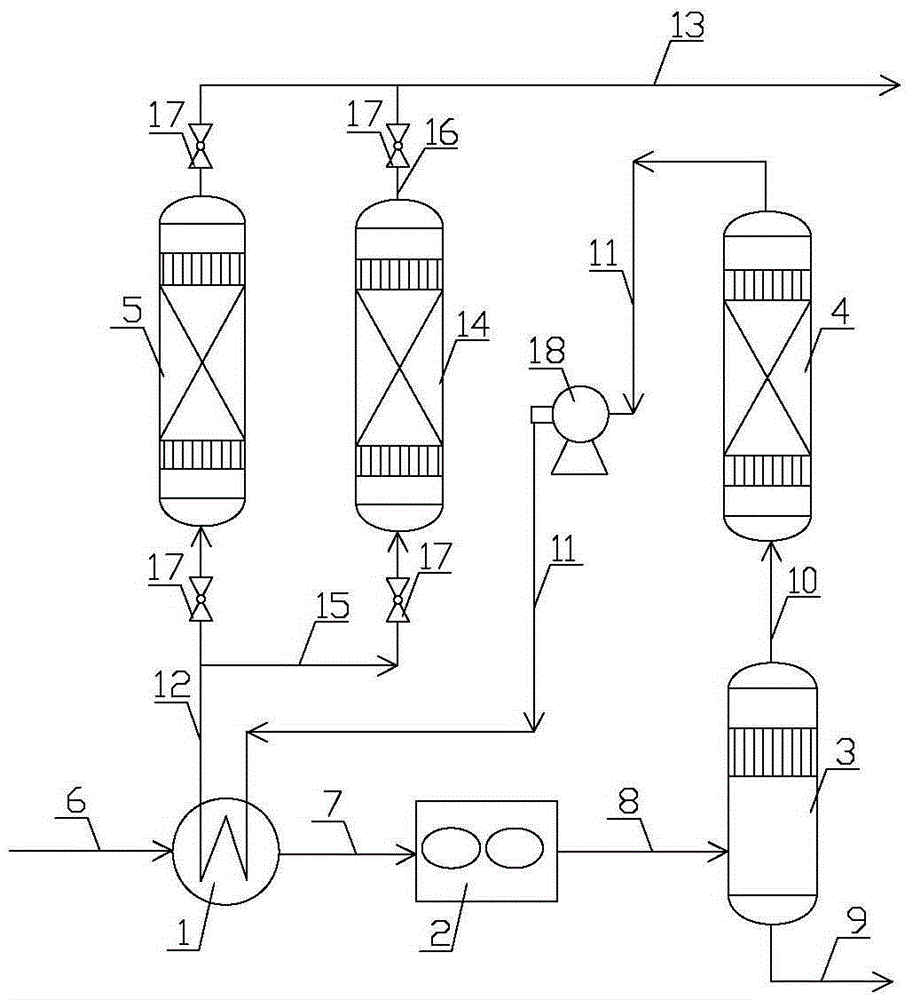

[0021] Embodiment 2, as attached figure 1 As shown, the special device for the gas-phase mercury removal method based on chemical adsorption includes a heat energy recovery device 1, an air cooler 2, a liquid separation tank 3, a drying filter 4, and an adsorption tower 5; the heat medium inlet of the heat energy recovery device 1 is fixed A raw material gas pipeline 6 is installed, an air cooler feed line 7 is fixedly installed between the heat medium outlet of the heat energy recovery device 1 and the inlet of the air cooler 2, and an air cooler feed line 7 is fixedly installed between the air cooler 2 and the feed port of the liquid separation tank 3 Liquid separation tank feed line 8, sewage discharge pipeline 9 is fixedly installed at the bottom of liquid separation tank 3, mercury-containing gas pipeline 10 is fixedly installed between the top of liquid separation tank 3 and the feed inlet of drying filter 4, and the dry filter A dry mercury-containing gas pipeline 11 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap