Low-temperature denitration device and method for denitration through low-temperature denitration device

A low-temperature denitrification and denitrification technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as catalyst deactivation, increase reaction contact surface and probability, improve denitrification efficiency, and improve low-temperature denitrification capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

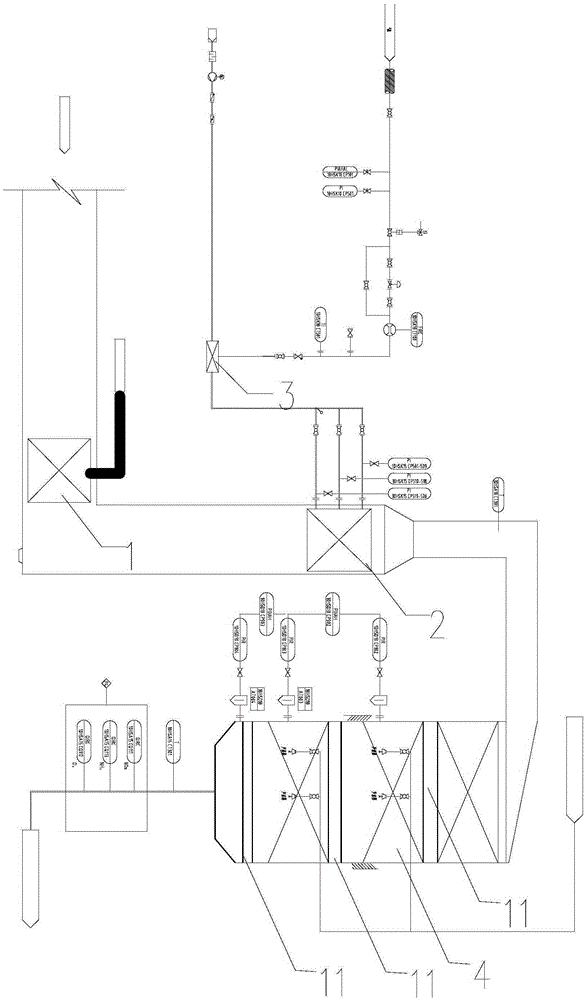

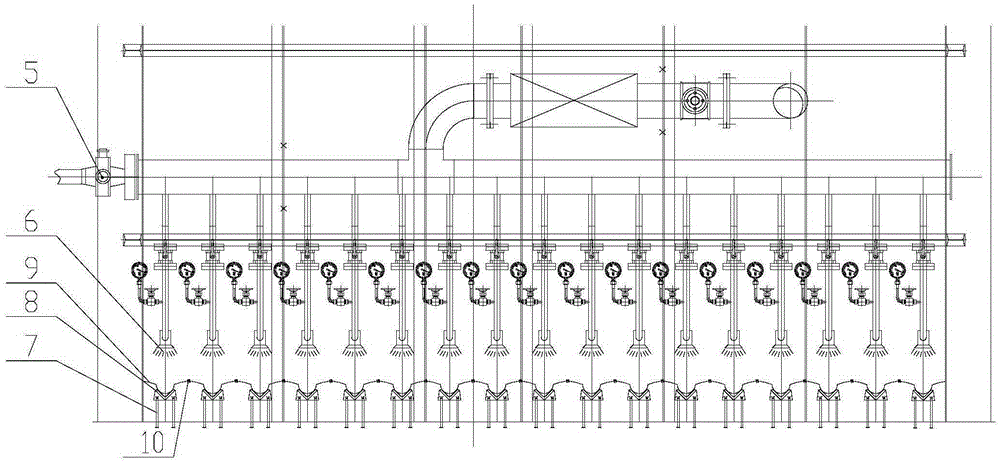

[0023] Embodiment 1: A kind of low temperature denitrification device, its structure is as follows figure 1 As shown, it includes an ammonia adding device 2, a mixing device 3 and a reaction device 4, the ammonia adding device 2 is embedded and connected in the flue, the mixing device 3 and the reaction device 4 are placed outside the flue, and the ammonia adding device The outlet of 2 communicates with the inlet of the mixing device 3, and the inlet of the reaction device 4 communicates with the outlet of the mixing device 3; it also includes a powder adding device 1 placed inside the flue, and the powder adding device 1 The outlet communicates with the inlet of the mixing device 3; the structure of the powder adding device 1 is as follows: figure 2 As shown, at least one group of spreading devices are included, the spreading devices include mist spray gun 6 and impact spray gun 7, the mist spray gun 6 is arranged vertically downward, and the impact spray gun 7 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com