A kind of UV pressure glue curing device and its pressure glue curing method

A curing device and gluing technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of uneven UV glue layer, easy generation of air bubbles, unadjustable thickness of UV glue layer, etc. To achieve the effect of simple operation and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

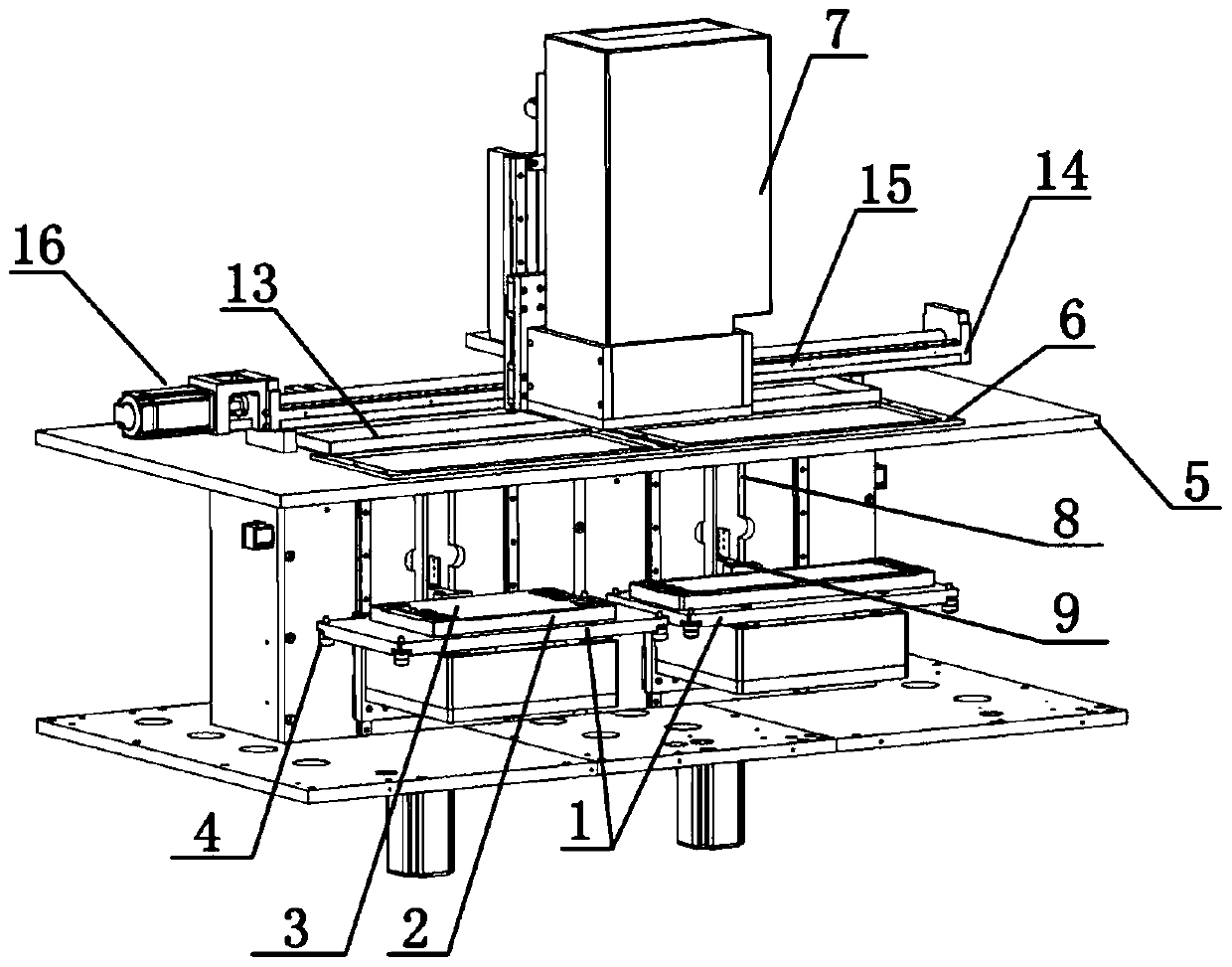

[0048] Depend on figure 1 , figure 2 and image 3 It can be seen that the UV glue curing device provided by the present invention includes a glue pressing unit, a curing unit and an electric control unit, and the electric control unit is electrically connected with the glue pressing unit and the curing unit, and is used to control the operation of the glue pressing unit and the curing unit.

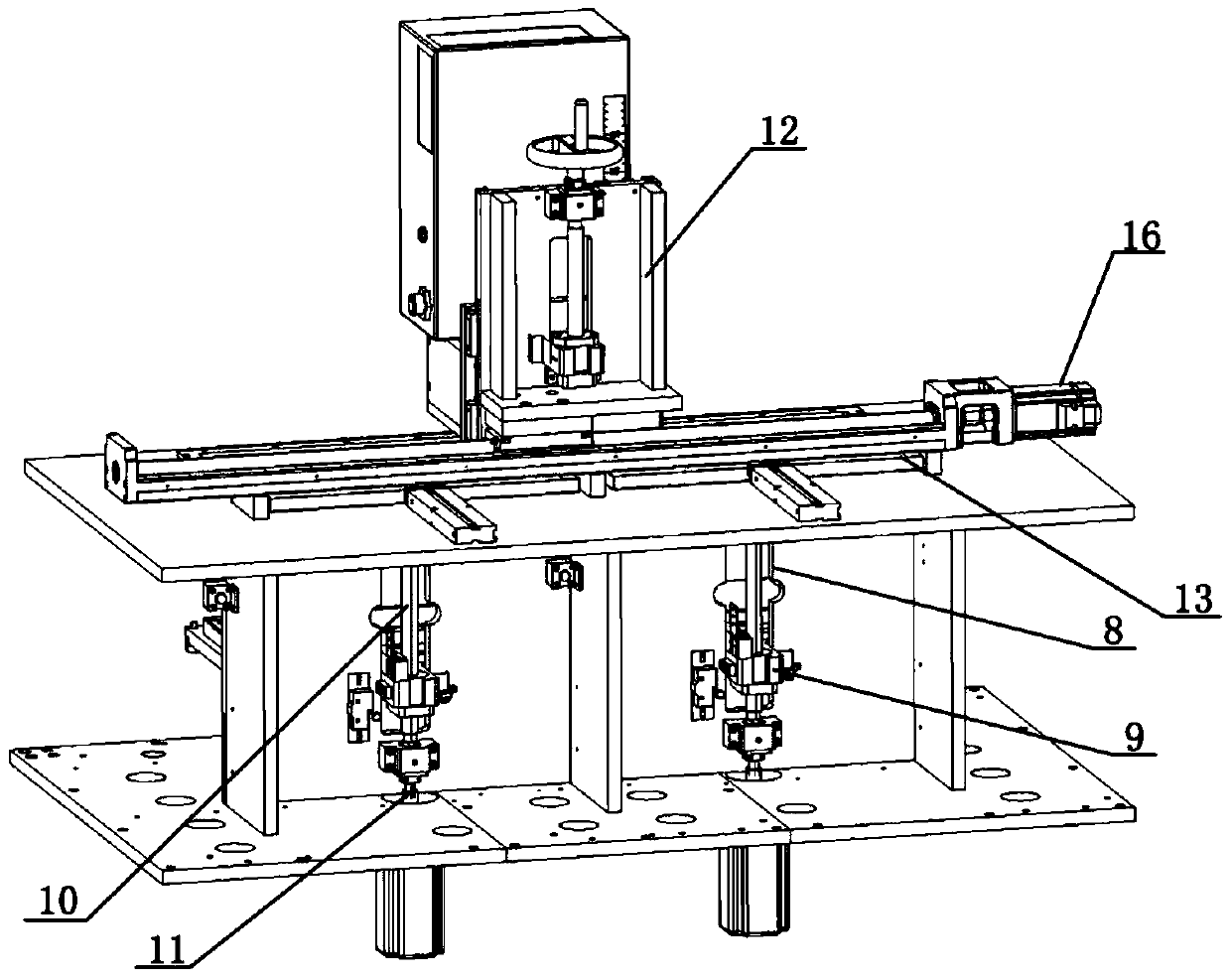

[0049] The gluing unit includes a lifting platform 1 and a pressing plate 5. The lifting platform 1 is a liftable platform. The lifting platform 1 is provided with a set 2, and the upper surface of the set 2 is provided with a groove 3 for accommodating objects to be glued and cured. A differential head 4 is arranged on the table 1, and the height of the differential head 4 is adjusted to be between the height of the object to be glued and cured in the groove 3 and the UV adhesive layer coated on the surface of the object to be glued and cured. The pressing plate 5 is a horizontal plat...

Embodiment 2

[0058] On the basis of Embodiment 1, this Embodiment 2 provides a UV adhesive curing device, the number of the shading device 13 , the glass panel 6 and the lifting platform 1 are the same and at least one. The curing unit also includes a UV lamp horizontal movement mechanism, which is located below the UV lamp lifting mechanism 12. The UV lamp horizontal movement mechanism includes a slide table 14 installed on the pressing plate 5. The slide table 14 is provided with a KK module 15, and the KK module One end of 15 is provided with a driving device 16; driven by the driving device 16, the UV lamp lifting mechanism drives the UV lamp 7 to slide along the KK module 15. When the number of shading device 13, glass panel 6 and lifting table 1 is more than one, through the UV lamp horizontal movement mechanism of the curing unit, the UV lamp lifting mechanism drives the UV lamp 7 to slide in the horizontal direction, so that multiple glues to be pressed can be realized. The cured i...

Embodiment 3

[0060] On the basis of embodiment 2, when the shading device 13, the glass panel 6 and the lifting platform 1 are respectively two, and the UV lamp 7 is located above the position between the first glass panel and the second glass panel of the pressing plate 5, as Figure 4 As shown, the method steps of using the UV adhesive curing device for adhesive curing are as follows:

[0061] S10, placing the first object to be glued and cured in the groove of the first lifting platform, and coating the surface of the first object to be glued and cured with UV glue;

[0062] S20, glueing the UV adhesive layer of the first object to be glued and cured; at the same time, placing the second object to be glued and cured in the groove of the second lifting platform, and coating the surface of the second object to be glued and cured UV glue;

[0063] S30, the UV lamp 7 is moved above the first glass panel through the UV lamp horizontal movement mechanism, the first shading device is turned o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com