Automatic waste mobile phone detaching and recovering method and automatic work assembly line device thereof

A recycling method and assembly line technology, applied in the field of recycling and processing methods and devices for waste mobile phones, can solve problems such as lack of large-scale and mechanized operations, secondary pollution, and simplification of mobile phone recycling methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Preferred embodiments of the present invention are described in detail as follows:

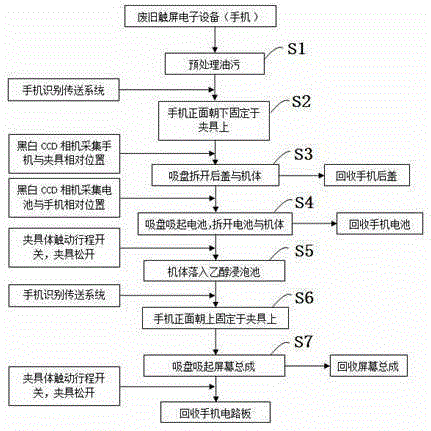

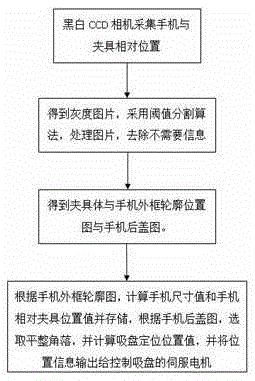

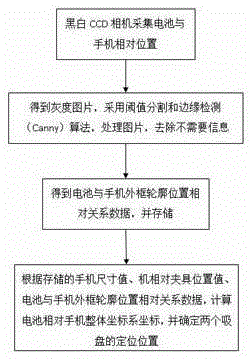

[0041] In this example, see Figure 1 to Figure 7 , an automatic assembly line device for automatic dismantling and recycling of waste mobile phones, which is composed of a first assembly line 400 and a second assembly line 410 controlled by a main control system in turn. The identification and pre-positioning system, the first mobile phone clamping station 401, the mobile phone back cover removal station 404 and the mobile phone battery removal station 406 are sequentially connected. Conveying device is formed, and the removal part output port of mobile phone back cover removal station 404 is corresponding to the entrance of rear cover collection box 405, and the removal part output port of mobile phone battery removal station 406 is corresponding to the entrance of battery collection box 408, and in the first assembly line 400 The first mobile phone clamping station 401 and the mobil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com