Valve module assembling integrated machine

An all-in-one machine and valve assembly technology, applied in the field of machinery, can solve the problems that cannot be solved, the practicability is poor, and the mechanical assembly of the valve seat and the valve tube cannot be realized, and the effect of high degree of automation, long service life and reasonable design can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

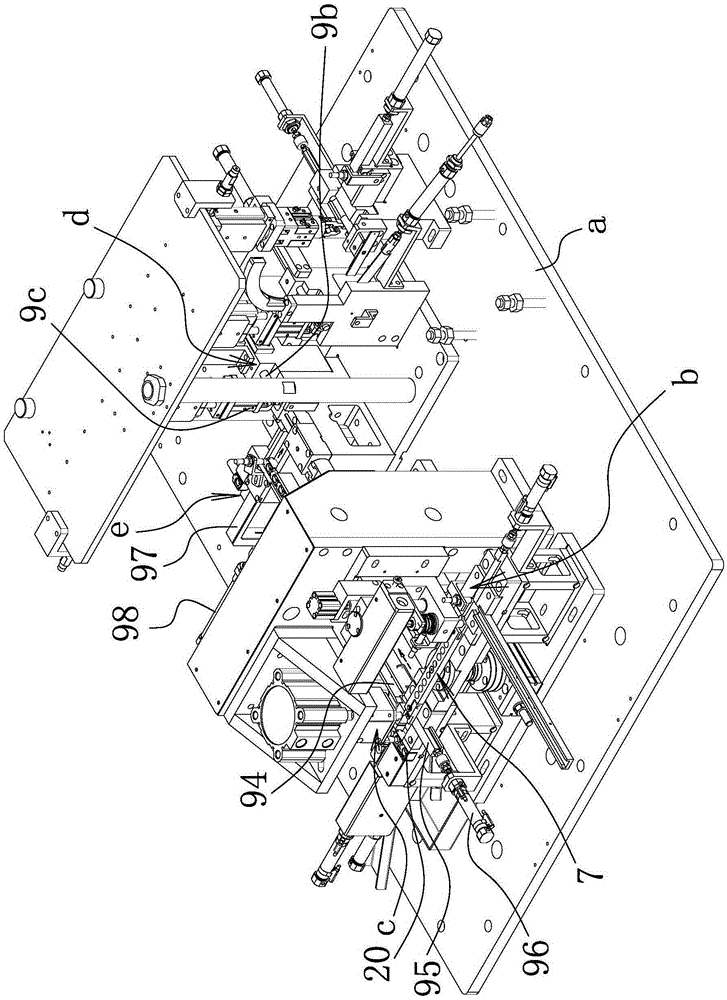

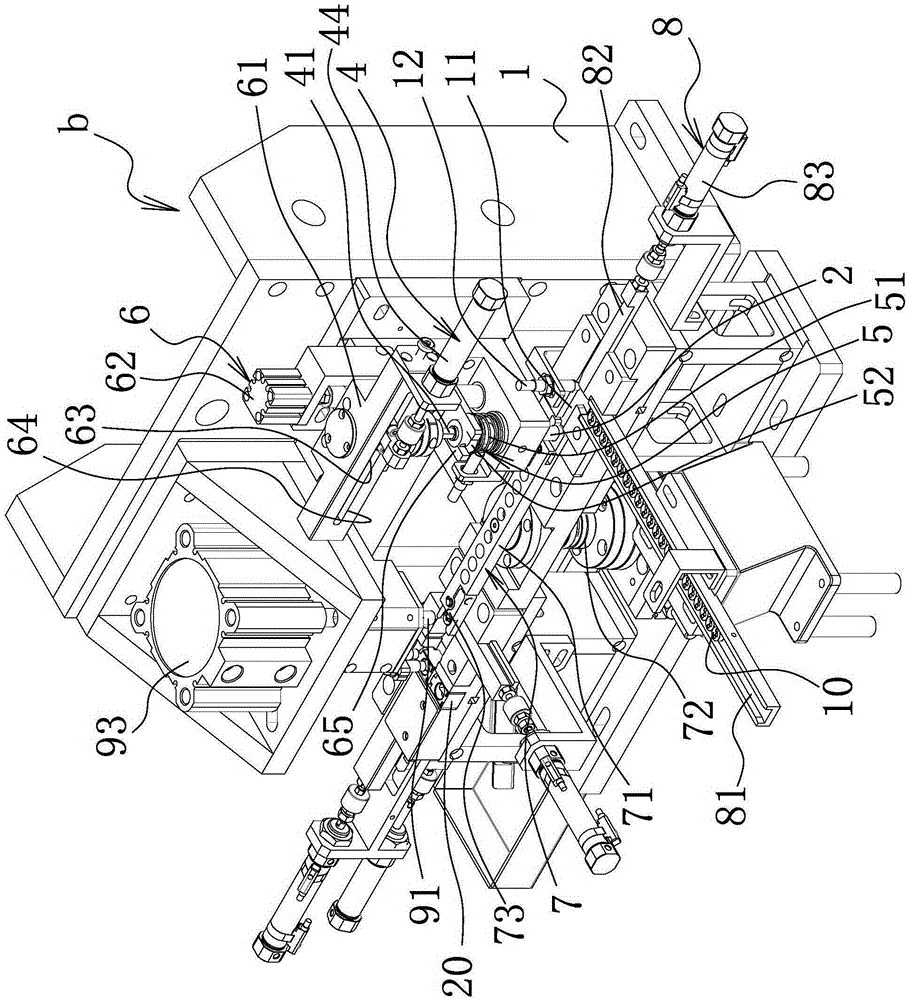

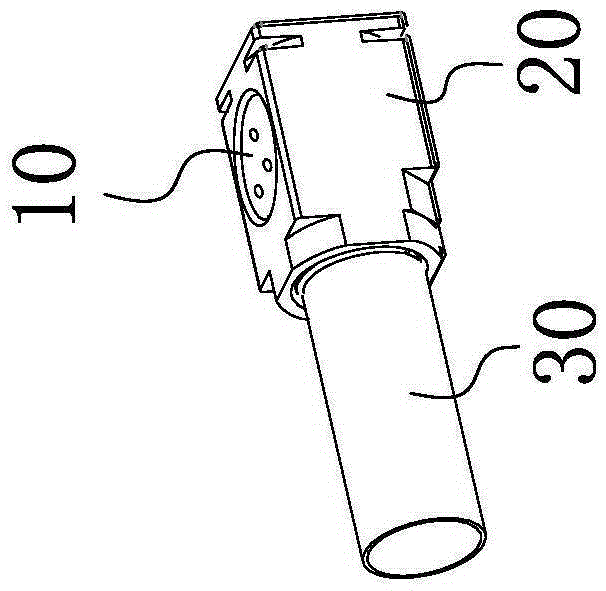

[0033] Such as figure 1 As shown, the integrated valve assembly machine includes a working platform a and a rotary elastic manipulator 7 which is arranged on the working platform a and can fix the valve core 10 in the circumferential direction. The working platform a is set on the cabinet f. When the rotary elastic manipulator 7 fixes the valve core 10 in the circumferential direction, the valve core selection alignment device b that can drive the valve core 10 to the set position is provided on the workbench a, and the workbench a is also equipped with a current The rotary elastic manipulator 7 rotates to the next station so that the synchronously rotated valve core 10 is pressed into the valve core riveting mechanism c in the valve seat 20. After the valve seat 20 is inside, one end of the valve tube 30 can be pressed into the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com