Blow-Fill-Seal Fully Automatic Aseptic Production Process for Water Needle Injection

A technology of aseptic production and production process, applied in bottle filling, bottling machine, liquid bottling, etc., can solve the problems of easy pollution in the production process, poor product adaptability, strong drug selectivity, etc., to achieve large market value and social The effect of value, high production efficiency and strong product adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

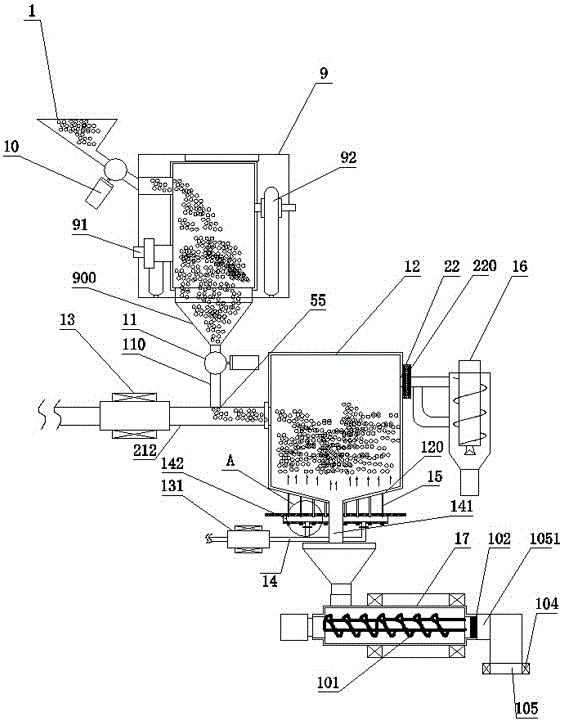

[0036] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

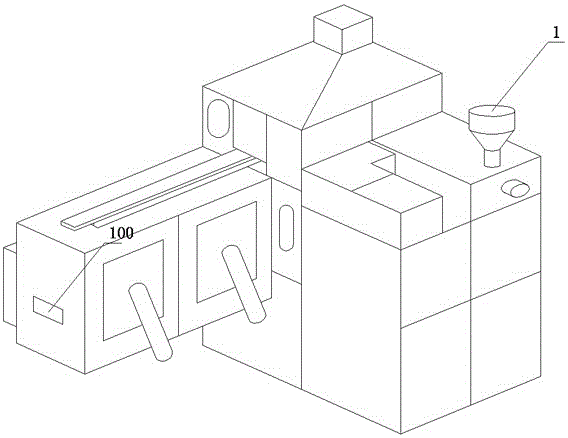

[0037] figure 1 It is a schematic structural diagram of related equipment for realizing the automatic blow-fill-seal production process of the present invention. The equipment has a high degree of automation, compact structure, and simple operation. Raw materials enter from the raw material hopper 1, and finally come out from the product outlet 100, and the whole process is produced by aseptic operation. .

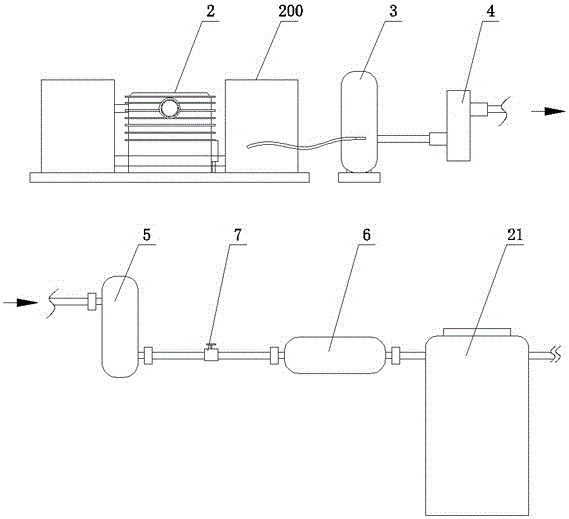

[0038] figure 2It is a schematic diagram of the production equipment of sterile air, and its sterile air production process: the air is separated by the air compressor 2 through the oil-water separator 200 and stored in the first air storage tank 3, and the first air storage tank 3 is connected in turn Fine filter 4, activated carbon filter 5, sterilizing filter 6, a pressure reducing valve 7 is arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com