3D printing equipment

A 3D printing and equipment technology, applied in the field of 3D printing, can solve the problems affecting the quality of printed products, the inability to accurately control the temperature of the filament, and the difficulty in meeting the requirements of printing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

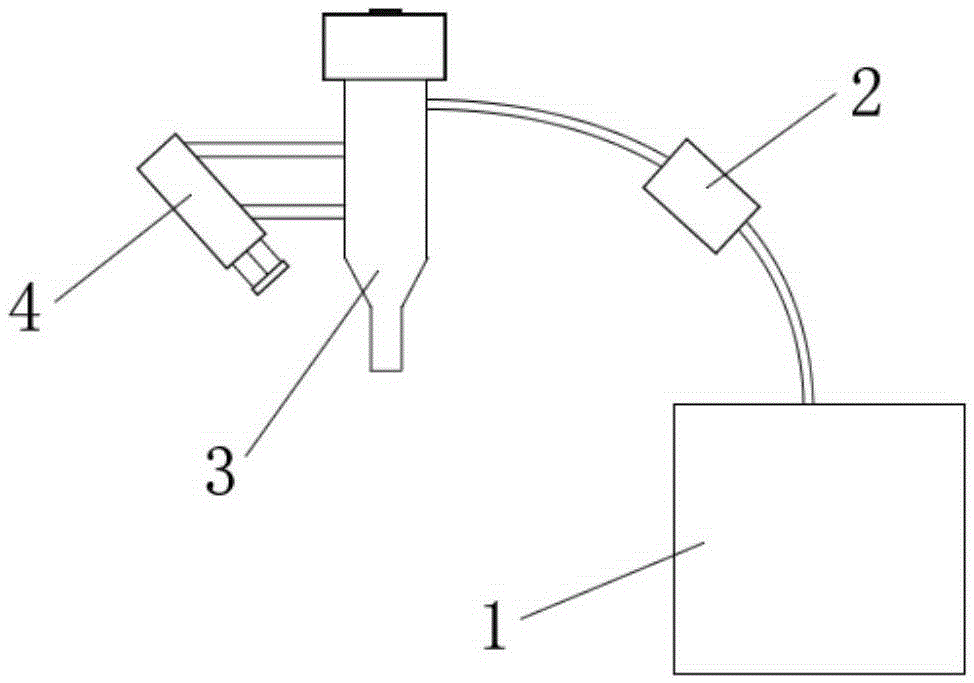

[0027] see figure 1 , the present invention discloses a 3D printing device, comprising a stocker 1, a peristaltic pump 2, an extrusion head 3, an ultraviolet light curing device 4, a printing tray, an X-axis motion mechanism, a Y-axis motion mechanism, a Z-axis motion mechanism and controller, where:

[0028] The stocker 1 is filled with liquid photosensitive liquid material. In this embodiment, the photosensitive liquid material is a photosensitive hydrogel material, and of course other types of photosensitive liquid materials can also be used, which are not specifically limited in the present invention. The components of photosensitive hydrogel materials mainly include hydrogel, UV curing agent and functional materials. The hydrogel is used as the matrix material, and the UV curing agent is used to enhance or control the curing reaction under UV-induced conditions. Functional materials It is the material added according to the specific printing sample requirements, such as...

Embodiment 3

[0039] The working process of the 3D printing device in this embodiment is as follows:

[0040] 1. The controller controls the movement of the X-axis movement mechanism, the Y-axis movement mechanism and the Z-axis movement mechanism to determine the position of the extrusion head 3 and the printing tray, that is, determine the printing coordinate position.

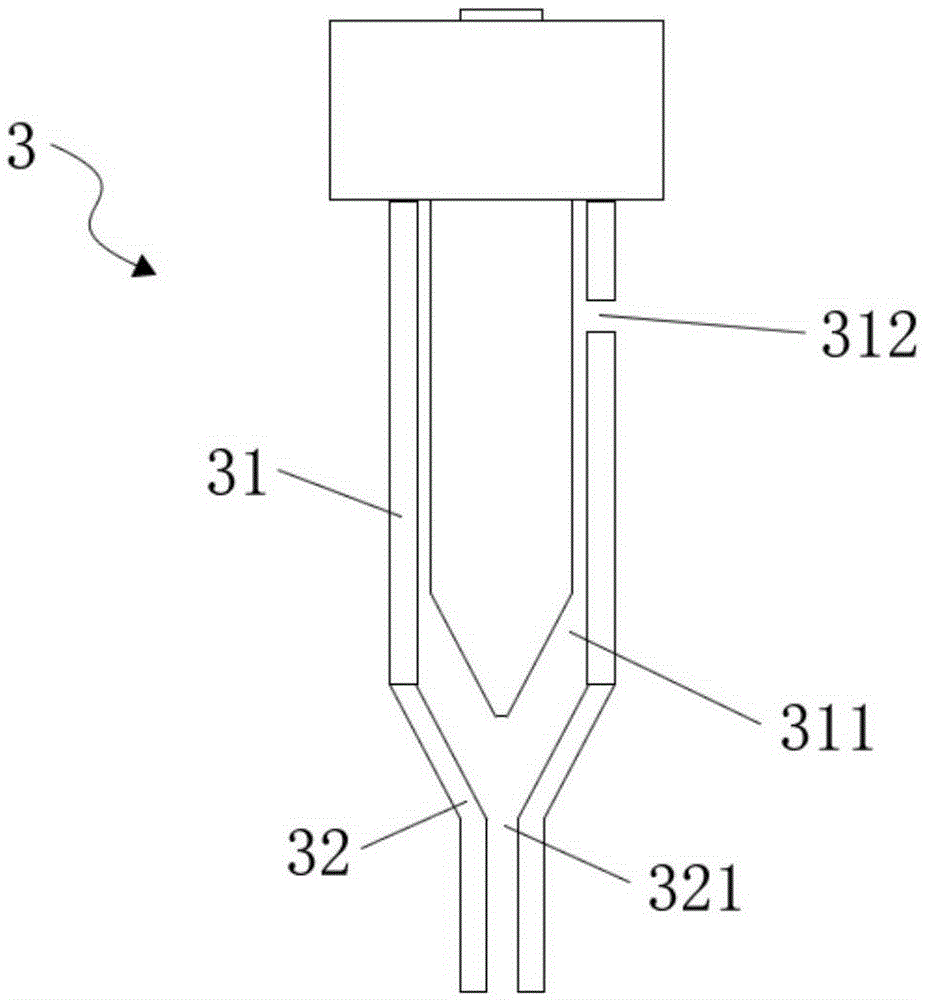

[0041] 2. The controller controls the operation of the peristaltic pump 2, and the peristaltic pump 2 transports the liquid photosensitive liquid material to the extrusion head 3, and the photosensitive liquid material is extruded from the nozzle 32.

[0042] 3. After the photosensitive liquid material is extruded from the nozzle 32 and separated from the nozzle 32, it falls to the printing tray. At this time, the light spot A generated by the ultraviolet light curing device 4 acts on the photosensitive liquid material, and the photosensitive liquid material is quickly cured.

[0043] 4. Repeat the above steps 1-3 to work...

Embodiment 2

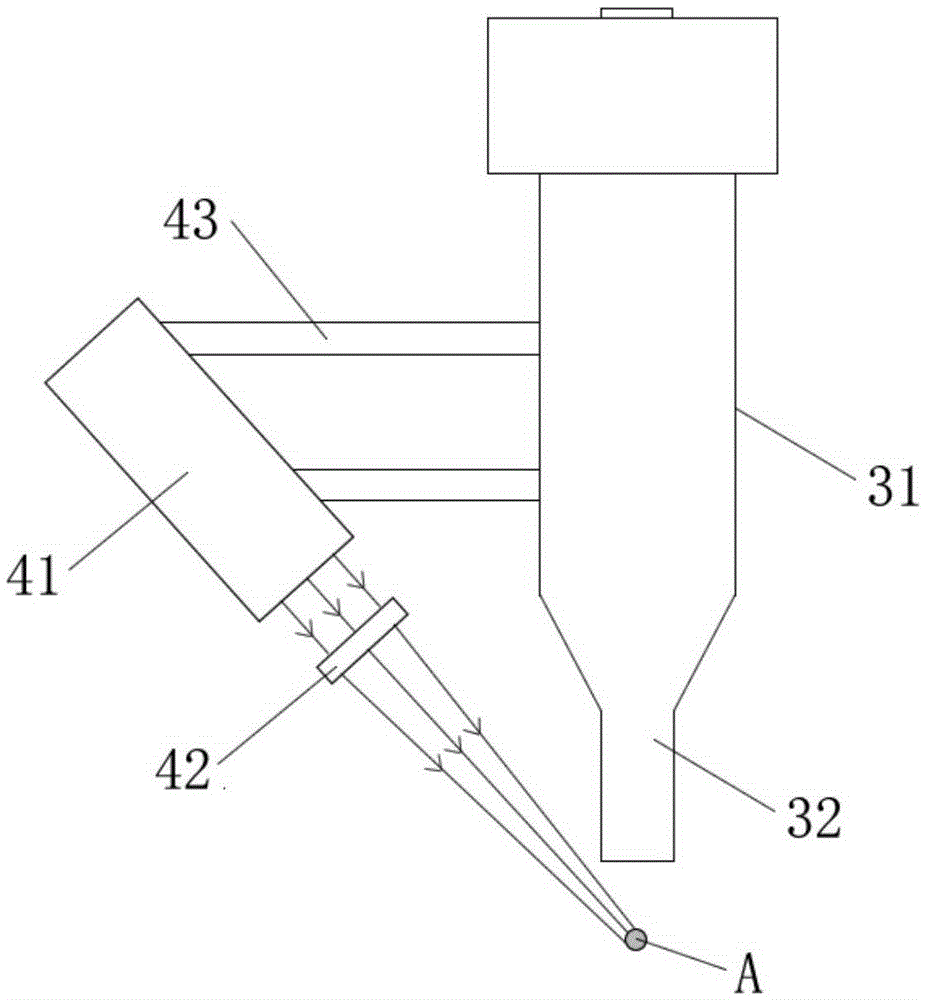

[0045] The difference between this embodiment and the first embodiment lies in that the structure of the ultraviolet curing device 4 is different.

[0046] Cooperate Figure 4 and Figure 5 As shown, in the present embodiment, the ultraviolet curing device 4 includes a housing 41', a group of ultraviolet light sources 42' and a reflector 43', wherein:

[0047] refer to Figure 5 As shown, the casing 41' is sheathed outside the main casing 31.

[0048] The ultraviolet light source 42' and the reflector 43' are disposed between the casing 41' and the main housing 31, and the reflector 43' is located below the ultraviolet light source 42'. The ultraviolet light source 42' adopts ultraviolet LED point light source, and its wavelength is 350~400nm. The number of ultraviolet light sources 42' can be selected according to operation requirements such as printing speed and curing efficiency, and is not specifically limited in the present invention.

[0049] The output beam of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com