Multi-rotor-wing unmanned aircraft

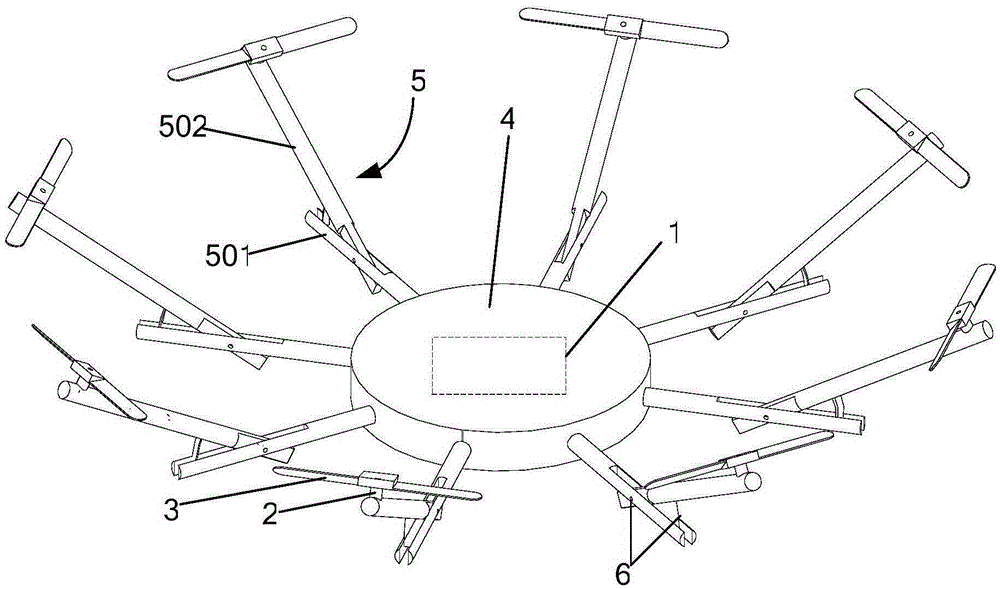

A multi-rotor unmanned and aircraft technology, applied in the field of unmanned aircraft, can solve the problems of poor environmental adaptability, poor flight stability, etc., and achieve the effect of maintaining stability, high flight stability, and shortening the time for adjusting balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

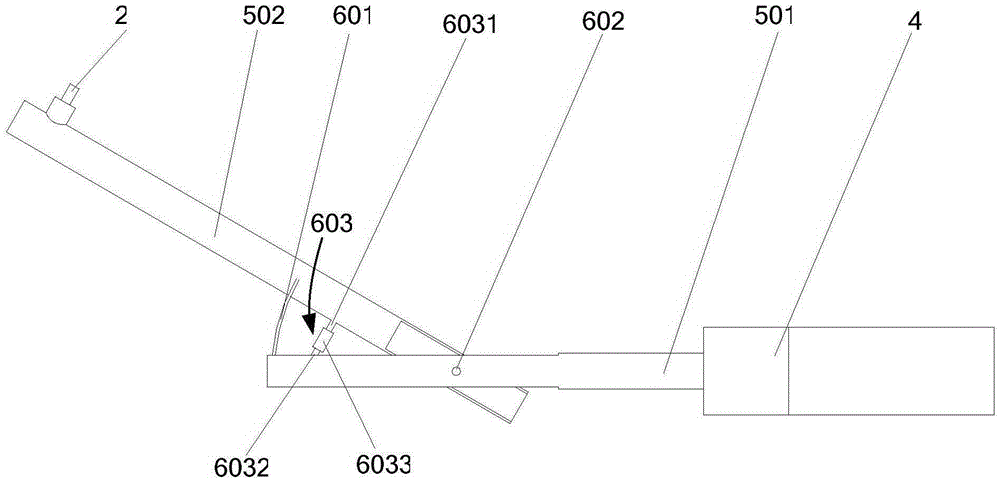

[0028] Such as figure 2 As shown, the connecting piece 6 includes: a reed 601, a pin shaft 602 and a tension member 603. The pin shaft 602 is arranged on the side close to the body 4 to connect with the strut 501 and the swing rod 502 respectively, and the reed 601 is arranged on a side far away from the body 4. One side is respectively connected with the strut 501 and the swing rod 502 , the tension member 603 is arranged between the pin shaft 602 and the reed 601 , and the tension member 603 is respectively connected with the strut 501 and the swing rod 502 .

[0029] The tension member 603 includes an upper screw 6031, a lower screw 6032 and a threaded tube 6033. The upper screw 6031 is connected with the swing rod 502, the lower screw 6032 is connected with the strut 501, and the threaded tube 6033 is connected with the upper screw 6031 and the lower screw 6032 respectively. The upper screw 6031 and the lower screw 6032 are provided with external threads, and the upper an...

Embodiment 2

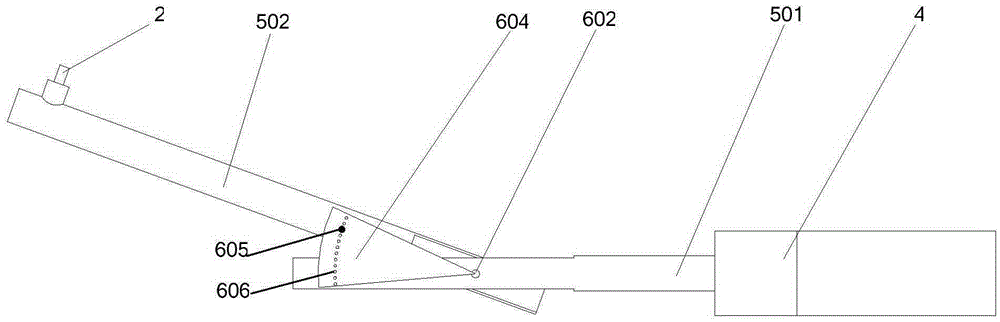

[0033] Such as image 3As shown, the connector 6 includes: a fan-shaped block 604, a pin shaft 602 and a latch 605. The circular center of the fan-shaped block 604 is arranged on the side close to the body 4 and is respectively connected to the strut 501 and the swing rod 502 through the pin shaft 602. The fan-shaped block 604 The arc end of the arc end is arranged on the side away from the body 4, and the lower plane of the sector block 604 is connected with the swing rod 502, and a plurality of positioning holes 606 are arranged on the arc inner side of the arc end of the sector block 604, and the bolt 605 is provided with threads, correspondingly Specifically, a threaded hole is provided on the swing rod 502 at a position corresponding to the positioning hole, and the pin 605 is screwed to the swing rod 502 through the positioning hole 606 .

[0034] The process of adjusting the inclination angle between the propeller 3 and the body 4 using the connector structure of this e...

Embodiment 3

[0037] Such as Figure 4 As shown, the connector 6 includes: a pin shaft 602, a push rod 607, a slider 608 and a locking block 609. The pin shaft 602 is arranged on the side close to the body 4 to connect with the strut 501 and the swing rod 502 respectively, and the slider 608 is arranged The side away from the body 4 is socketed and connected with the strut 501. The strut 501 is provided with external threads, and the locking block 609 is provided with internal threads. , the push rod 607 is connected with the swing rod 502 and the slider 608 respectively.

[0038] The process of adjusting the inclination angle between the propeller 3 and the body 4 using the connector structure of this embodiment is as follows:

[0039] When the external wind is strong and the inclination angle between the propeller 3 and the body 4 needs to be increased, the locking block 609 on the inside of the slider 608 is rotated inwardly, and then the slider 608 is slid inwardly, and the slider 608 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com