Non-contact detection device and method for pitch circle diameter of steel wire rope for mining

A technology of pitch circle diameter and detection device, which is used in transportation, packaging, elevators, etc., can solve the problems of inability to detect the pitch circle diameter of steel wire rope, difficult to accurately obtain the pitch circle diameter, and the cross section is not, and achieve high-precision non-contact dynamic detection. , Improve the minimum resolution, good directionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

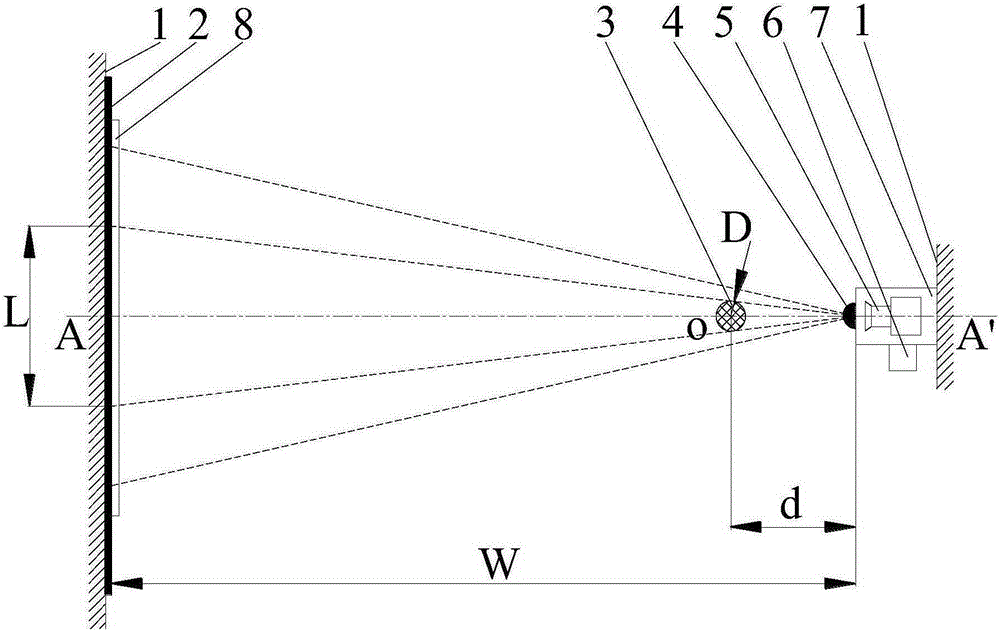

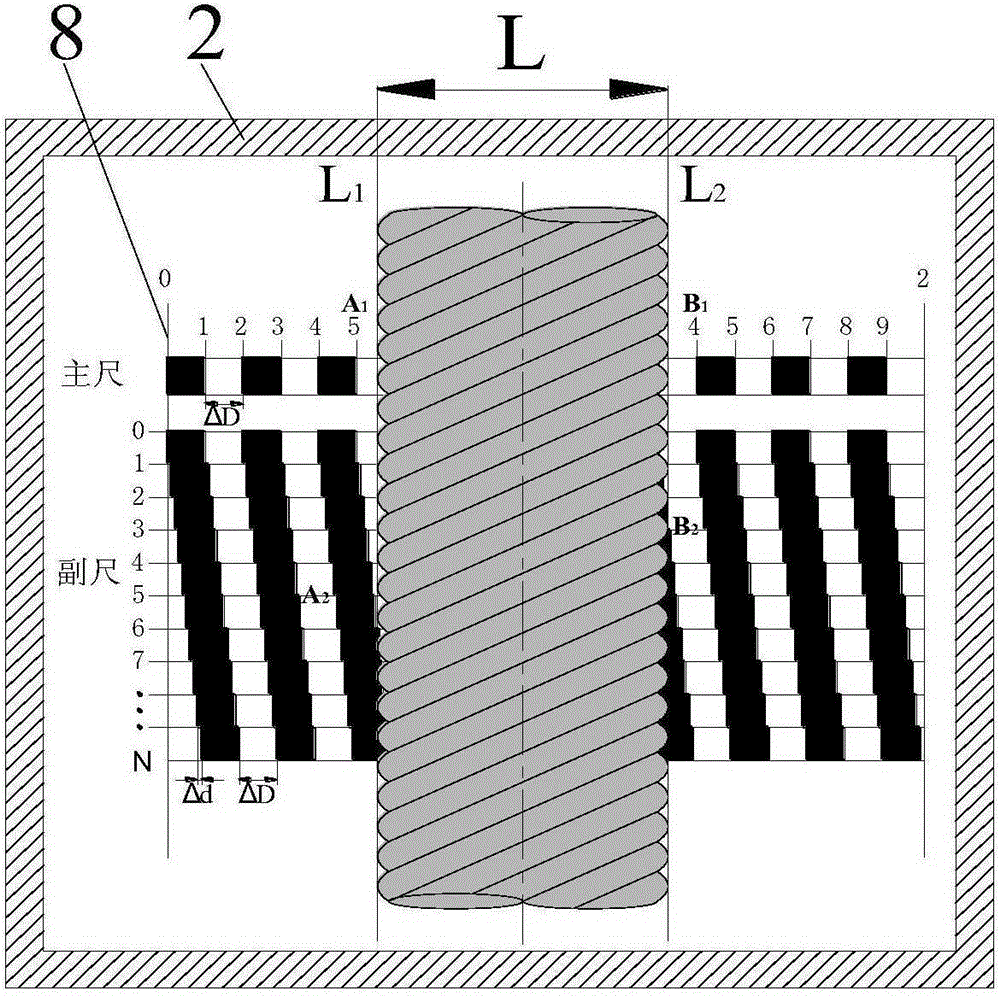

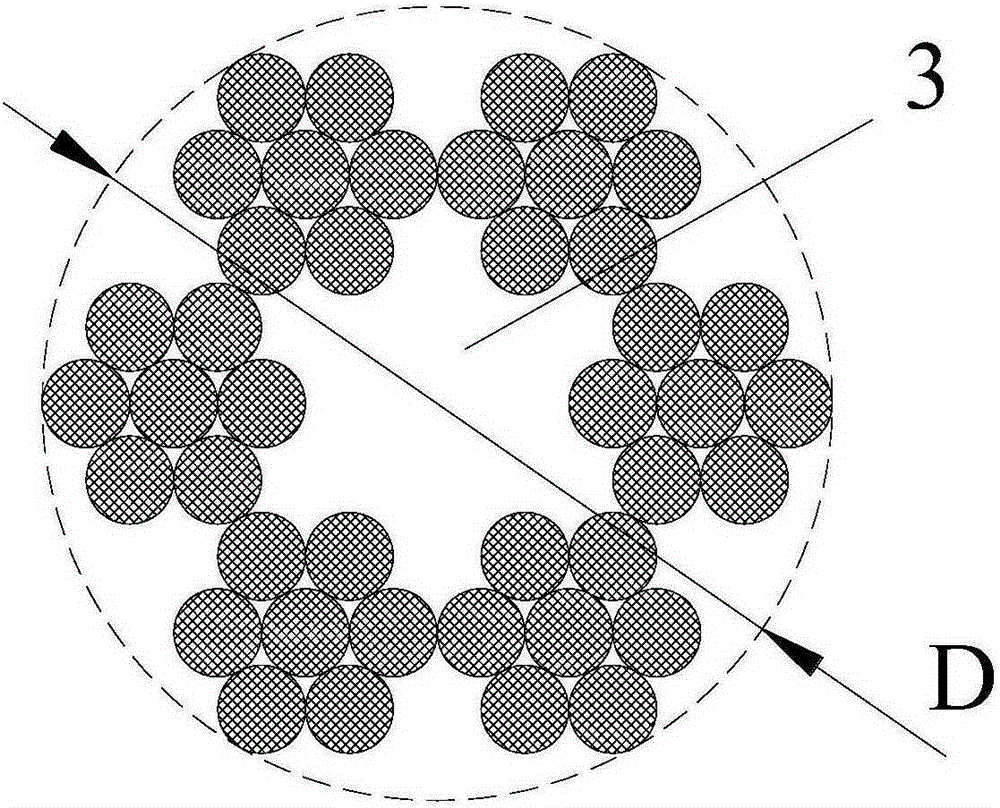

[0028] The mine steel wire rope pitch circle diameter non-contact detection device of the present invention mainly consists of a laser 4, a camera 5, a base 7, a signal processor 6, an imaging plate 2, and an image vernier 8; the base 7 is fixed on the base platform 1, the laser 4, the camera 5, and the signal processor 6 are arranged at the bottom of the base 7, the laser 4 is located at the front of the base 7 and faces the wire rope 3, and irradiates the wire rope 3, and the camera 5 is located at the back of the laser 4 , the signal processor 6 is located at the bottom of the base 7, the laser 4 and the camera 5 are respectively connected with the signal processor 6, and the steel wire rope 3 is irradiated by the laser 4, and the central axis AA' of the light curtain of the laser 4 and the central axis of the steel wire rope 3 O are perpendicular to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com