A method of acid analysis-hydrogen peroxide catalytic oxidation treatment of high-concentration waste emulsion

A waste emulsion, catalytic oxidation technology, applied in the oxidation water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Simple process, small footprint and high oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

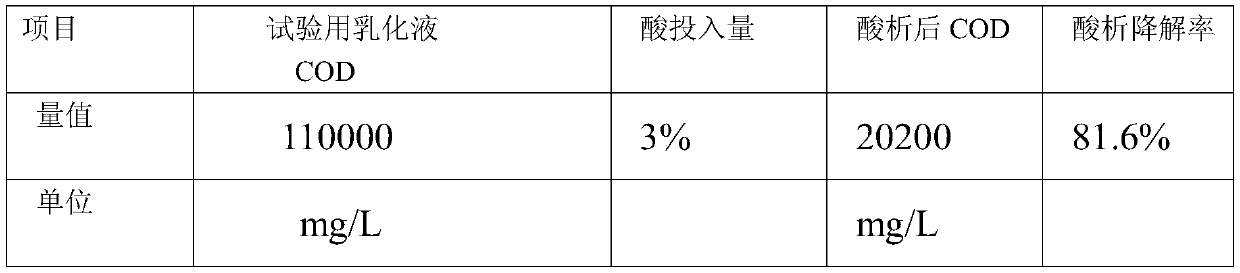

Embodiment 1

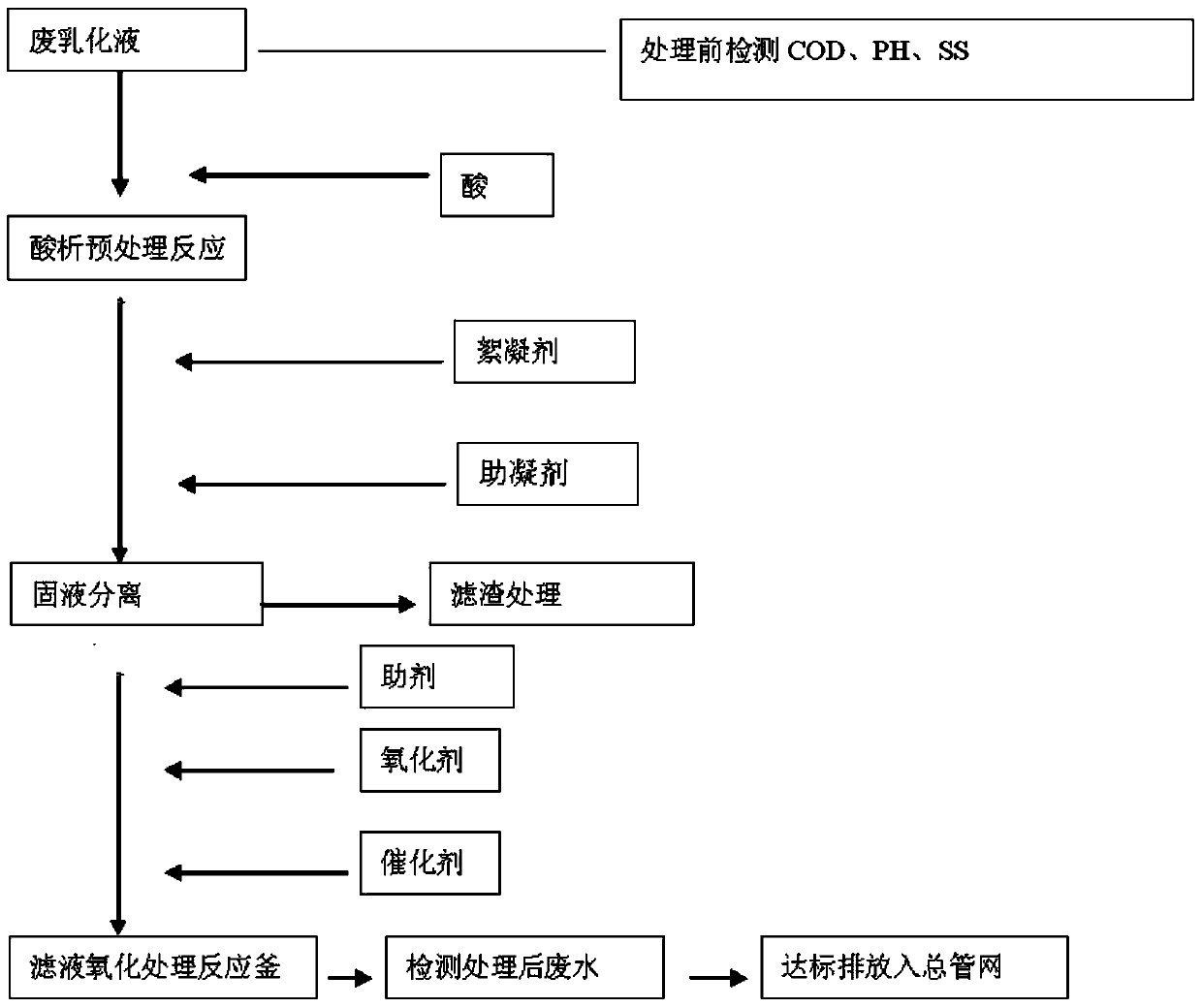

[0027] according to figure 1 The process flow chart of acid analysis-catalyzed oxidation of hydrogen peroxide of the present invention to treat high-concentration waste emulsion, carry out the processing of high-concentration waste emulsion, the method is as follows:

[0028] The waste emulsion comes from a diesel engine manufacturing company

[0029] (1) Before treatment, detect the COD, pH, SS (suspended solids concentration) and oil content of the waste emulsion to be treated. Measure COD with potassium chlorate method; measure pH value with pH test paper, and use glass electrode method for final detection; measure oil content with infrared spectrophotometer; measure SS with infrared spectrophotometer. The test results are shown in Table 1.

[0030] Table 1 COD, pH, SS and oil content in waste emulsion

[0031] project

[0032] (2) adding the mass concentration of 3% of the total mass of the waste emulsion to 30% sulfuric acid in the waste emulsion, stirring fo...

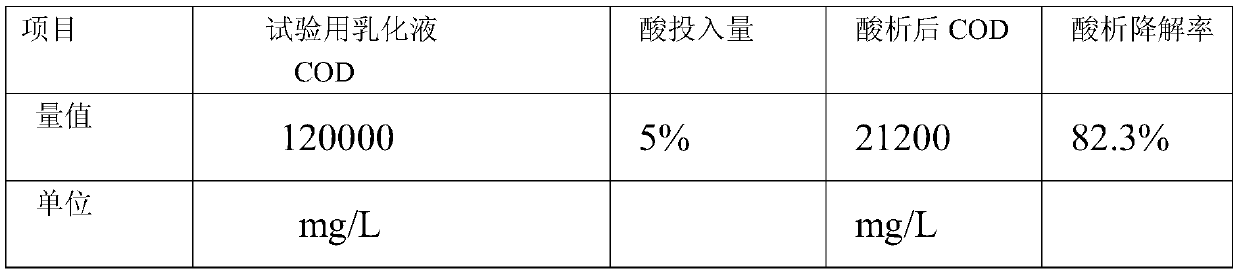

Embodiment 2

[0043] according to figure 1 The process flow chart of acid analysis-catalyzed oxidation of hydrogen peroxide of the present invention to treat high-concentration waste emulsion, carry out the processing of high-concentration waste emulsion, the method is as follows:

[0044] The waste emulsion comes from a diesel engine manufacturing company

[0045] (1) Before treatment, detect the COD, pH, SS (suspended solids concentration) and oil content of the waste emulsion to be treated. Measure COD with potassium chlorate method; measure pH value with pH test paper, and use glass electrode method for final detection; measure oil content with infrared spectrophotometer; measure SS with infrared spectrophotometer. The test results are shown in Table 1.

[0046] Table 1 COD, pH, SS and oil content in waste emulsion

[0047] project

COD

oily

SS

pH

Quantity

120000

4000

800

11

unit

mg / L

mg / L

mg / L

[0048] (2) addin...

Embodiment 3

[0058] according to figure 1 The process flow chart of acid analysis-catalyzed oxidation of hydrogen peroxide of the present invention to treat high-concentration waste emulsion, carry out the processing of high-concentration waste emulsion, the method is as follows:

[0059] The waste emulsion comes from a diesel engine manufacturing company

[0060] (1) Before treatment, detect the COD, pH, SS (suspended solids concentration) and oil content of the waste emulsion to be treated. Measure COD with potassium chlorate method; measure pH value with pH test paper, and use glass electrode method for final detection; measure oil content with infrared spectrophotometer; measure SS with infrared spectrophotometer. The test results are shown in Table 1.

[0061] Table 1 COD, pH, SS and oil content in waste emulsion

[0062] project

COD

oily

SS

pH

Quantity

90000

1100

500

9

unit

mg / L

mg / L

mg / L

[0063] (2) adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com