Spriulina polysacchride and preparation method thereof

A technology of spirulina polysaccharides and spirulina, which is applied in the field of natural medicine extraction and preparation, can solve the problems of no single polysaccharide extraction and application research, limitations, etc., and achieve the effect of inhibiting the proliferation of human liver cancer cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of preparation method of spirulina polysaccharide, specifically:

[0024] Take 2Kg of spirulina, add 40L of 0.5mol / L NaOH solution, stir and extract at a solution temperature of 60°C for 2 hours; after cooling, add 6mol / L HCl solution to adjust the pH value to 2.5; centrifuge to obtain a supernatant. Concentrate the supernatant to about 5 L, add 15 L of 95% edible ethanol, let it stand for 10 hours, and collect the precipitate by centrifugation to obtain 300 g of spirulina crude polysaccharide.

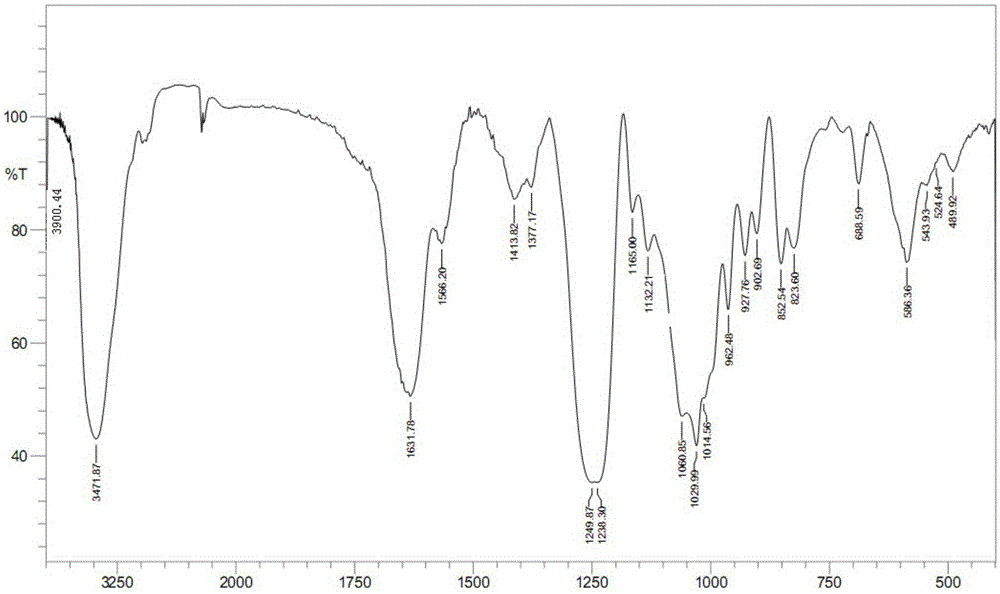

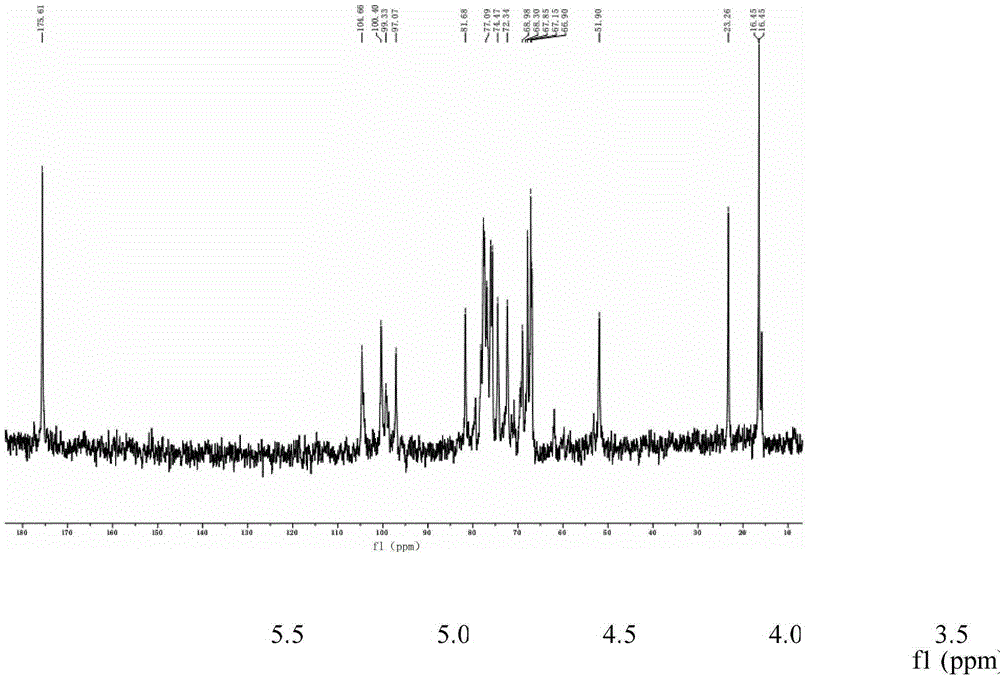

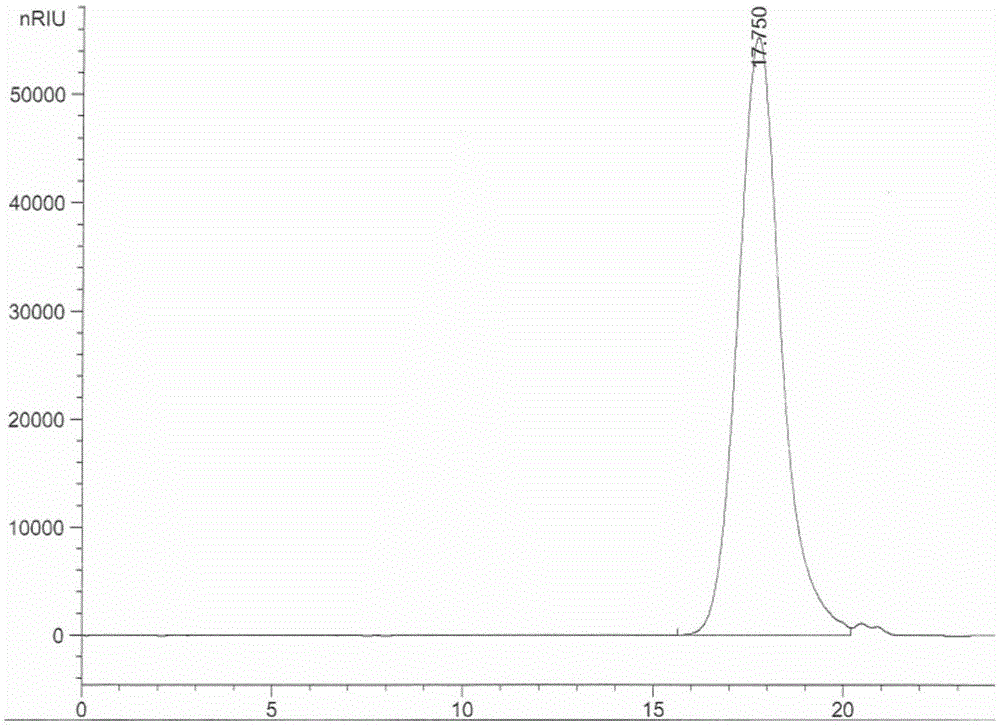

[0025] Take 200g of the above-mentioned spirulina crude polysaccharide, add 6L of water to dissolve; in a water bath at 35°C, add 0.5mol / LNaCl, 0.5mol / LNaAc; after 4.0mmol / L acetic acid; add 2L of 10% H2O2 dropwise at a constant speed; wait for 4 hours to react, and the reaction is complete Afterwards, 150 g of spirulina homogeneous polysaccharides were obtained by ultrafiltration. It is detected as a homogeneous polysaccharide by high performance gel chro...

Embodiment 2

[0026] Embodiment 2: a kind of preparation method of spirulina polysaccharide, specifically:

[0027] Take 2Kg of spirulina, add 20L of 0.5mol / L NaOH solution, stir and extract at a solution temperature of 60°C for 2 hours; after cooling, add 6mol / L HCl solution to adjust the pH value to 2; centrifuge to obtain a supernatant. Concentrate the supernatant to about 5 L, add 15 L of 95% edible ethanol, let it stand for 11 hours, and collect the precipitate by centrifugation to obtain 270 g of spirulina crude polysaccharide.

[0028] Take 200g of the above-mentioned spirulina crude polysaccharide, add 4L of water to dissolve; in a water bath at 35°C, add 0.5mol / LNaCl, 0.5mol / LNaAc; after 4.0mmol / L acetic acid; add 1L of 10% H2O2 dropwise at a constant speed; react for 4 hours, wait for the reaction to end Afterwards, ultrafiltration was carried out to obtain 143 g of spirulina homogeneous polysaccharide. It is detected as a homogeneous polysaccharide by high performance gel chroma...

Embodiment 3

[0029] Embodiment 3: a kind of preparation method of spirulina polysaccharide, specifically:

[0030] Take 2Kg of spirulina, add 60L of 0.5mol / L NaOH solution, stir and extract at 60°C for 2 hours; after cooling, add 6mol / L HCl solution to adjust the pH to 3; centrifuge to obtain the supernatant. Concentrate the supernatant to about 5 L, add 15 L of 95% edible ethanol, let it stand for 12 hours, and collect the precipitate by centrifugation to obtain 313 g of spirulina crude polysaccharide.

[0031] Take 200g of the above-mentioned spirulina crude polysaccharide, add 8L of water to dissolve; in a water bath at 35°C, add 0.5mol / LNaCl, 0.5mol / LNaAc; 4.0mmol / L acetic acid; add 3L of 10% H2O2 dropwise at a constant speed; , carried out ultrafiltration to obtain 144 g of spirulina homogeneous polysaccharide. It is detected as a homogeneous polysaccharide by high performance gel chromatography (HPGPC), and its weight average molecular weight is 9500Da.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com