Aqueous-phase demulsifier and preparation method thereof

A demulsifier and water-phase technology, which is applied in the field of water-phase demulsifier and its preparation, can solve the problems of increased difficulty in oil-water separation, limited types, and unsatisfactory performance, and achieves good interface participation ability, good viscosity reduction, and good performance. The effect of phase inversion demulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

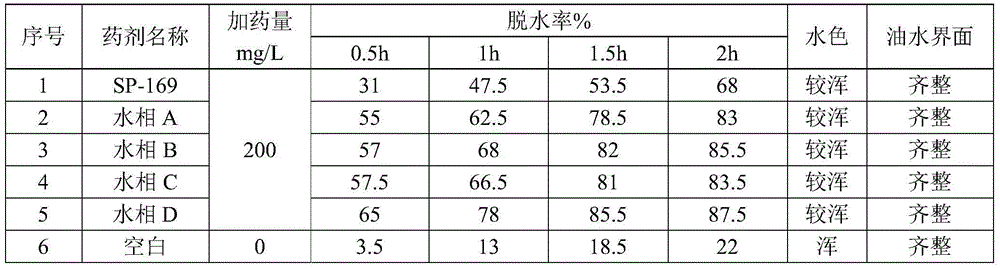

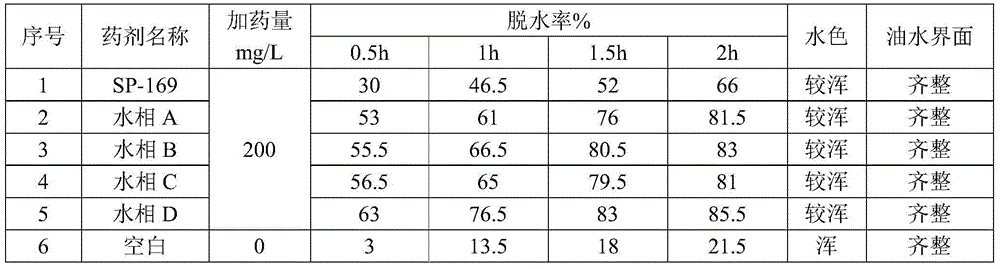

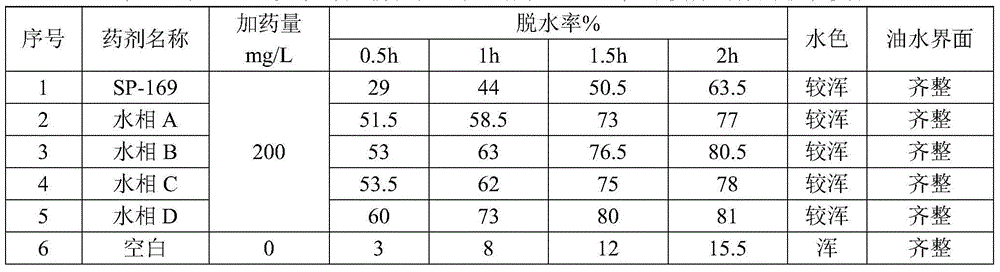

Examples

Embodiment 1

[0023] Embodiment 1: the preparation method of long-chain alkyl 1.0G polyamide-amine: in (1000ml) there-necked flask, add 27g (0.1mol) octadecylamine, 300g methyl alcohol, constant temperature reflux under magnetic stirring, bath temperature 60 ℃, After the raw material is completely dissolved, slowly add 86 g (1 mol) of methyl acrylate dropwise with a constant pressure dropping funnel, the rate of addition is one drop per second, after 24 hours of reaction under constant temperature stirring, a light yellow transparent liquid is obtained, and the reaction solution is static for 12 hours, with a white precipitate Precipitate, filter, and distill the filtrate under reduced pressure with an oil pump to obtain a yellow liquid, which is the 0.5G product; add 4.3g (0.01mol) of the 0.5G product to a three-necked flask, add 100g of methanol, keep the temperature at 60°C, and slowly add ethyl alcohol dropwise under stirring. Diamine 36.1g (0.6mol), the rate of addition is one drop per ...

Embodiment 2

[0024] Embodiment 2: the preparation method of water-phase demulsifier A: 70g formula long-chain alkyl 1.0G polyamide, 30g long-chain alkylbenzenesulfonic acid and 100g methanol are mixed to obtain water-phase demulsifier A.

Embodiment 3

[0025] Embodiment 3: the preparation method of water phase demulsifier B: 70g long-chain alkyl 1.0G polyamide-amine, 30g long-chain alkylbenzene sulfonic acid and 100g methanol are mixed to obtain water phase demulsifier B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com