Efficient heavy oil viscosity reducing agent and preparation method thereof

A heavy oil viscosity reducer and heavy oil technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficult mining and increased viscosity, and achieve reduced viscosity of heavy oil, good viscosity reduction, The effect of good interface engagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

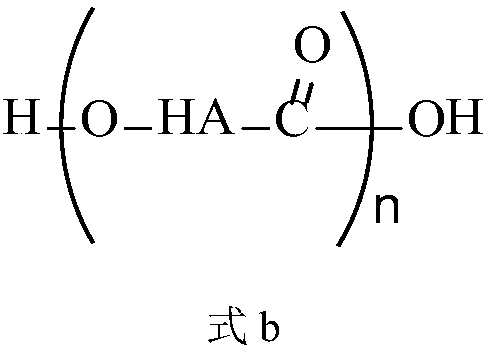

[0023] Active ingredient I humic acid condensation polymer (HA) in the present invention n , its specific preparation method includes: humic acid, triphenylphosphorus (PPh 3 ) and diethyl azodicarboxylate (DEAD) were added to the water separator containing a certain amount of toluene, refluxed to separate the water, slowly dripped concentrated sulfuric acid through the constant pressure dropping funnel, stirred at 60°C for 1 hour and then heated to 180±5°C, stop after 3 hours of reaction. Filtration, washing with water, separation, and recrystallization to obtain the condensed polymer (HA) n , the degree of condensation is 1 to 100.

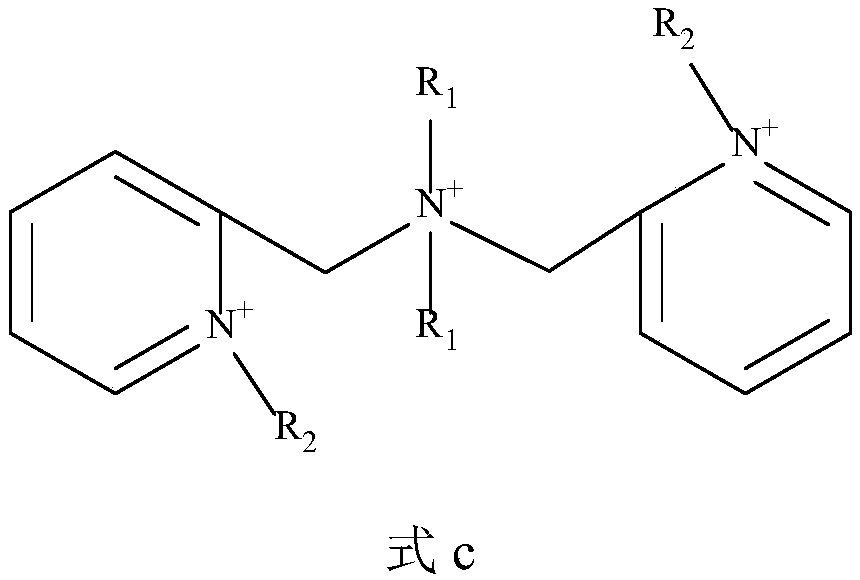

[0024] The specific preparation method of the active ingredient II N-dialkyl-N', N"-dialkyl-dimethylpyridinium ammonium salt (DDBA) of the present invention comprises:

[0025] (1) Dimethylpyridinium and alkyl iodide (R 1 -I; where R 1 for -(CH 2 ) x -CH 3 ; Among them, x is 0-15; R 2 for -(CH 2 ) y -CH 3 ; Among them, y is 0-15; when...

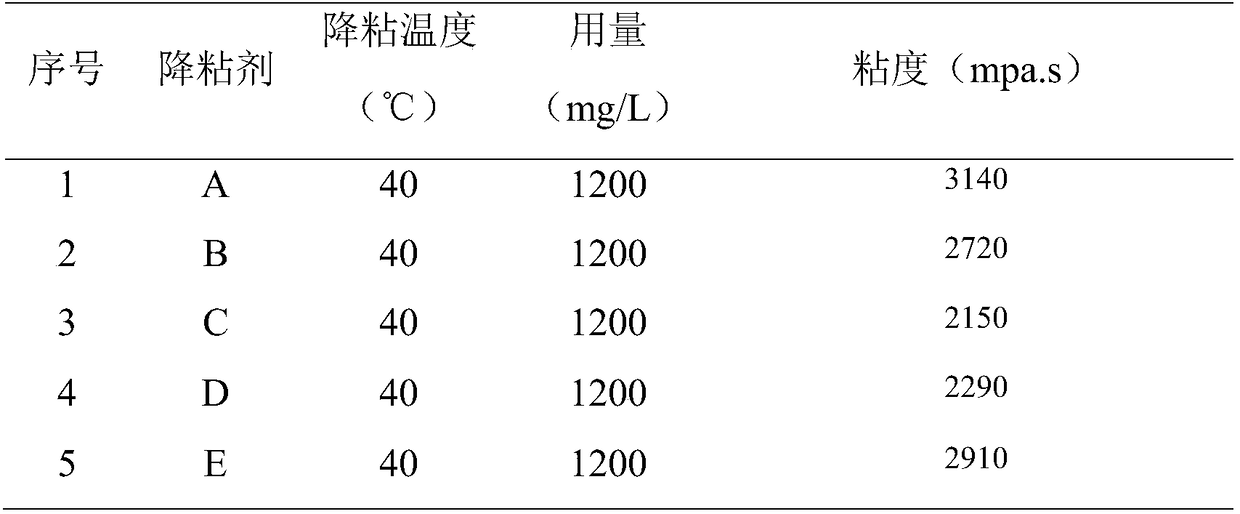

Embodiment 1

[0026] Embodiment 1: Preparation of novel composite heavy oil viscosity reducer A

[0027] 22.21g of humic acid, 3.8g of triphenylphosphine (PPh 3 ) and 4.183g of diethyl azodicarboxylate (DEAD) were added to a water separator containing 100ml of toluene, refluxed to separate the water, and slowly added concentrated sulfuric acid through a constant pressure dropping funnel, a total of 30ml, and stirred at 60°C for 1 hour Afterwards, the temperature was raised to 180±5°C, and the reaction was terminated after 3 hours. Filter, wash with water, separate, and recrystallize to obtain (HA) with a degree of condensation of 25 n .

[0028] 30g active ingredient I condensation polymer (HA) of humic acid n (n=25), 70g N-dialkyl-N', N"-dialkyl-dimethylpyridinium ammonium salt (DDBA) (x=15, y=15) and 100g ethanol are mixed uniformly to obtain a High-efficiency heavy oil viscosity reducer, marked as A, where (HA) n The mass ratio to DDBA is 3:7, (HA) n The mass ratio of the total mas...

Embodiment 2

[0029] Embodiment 2: the preparation of novel composite heavy oil viscosity reducer B

[0030] 22.21g of humic acid, 3.8g of triphenylphosphine (PPh 3 ) and 4.183g of diethyl azodicarboxylate (DEAD) were added to a water separator containing 100ml of toluene, refluxed to separate the water, and slowly added concentrated sulfuric acid through a constant pressure dropping funnel, a total of 30ml, and stirred at 60°C for 1 hour Afterwards, the temperature was raised to 180±5°C, and the reaction was terminated after 3 hours. Filter, wash with water, separate, and recrystallize to obtain (HA) with a degree of condensation of 25 n .

[0031] 40g active ingredient I condensation polymer (HA) of humic acid n (n=25), 60g N-dialkyl-N', N"-dialkyl-dimethylpyridinium ammonium salt (DDBA) (x=15, y=15) and 100g ethanol are mixed uniformly to obtain a High-efficiency heavy oil viscosity reducer, marked as A, where (HA) n The mass ratio with DDBA is 4:6, (HA) n The mass ratio of the tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com