Safety protection screen for building construction

A safety protection and building construction technology, applied in the direction of construction, building structure, house structure support, etc., can solve the problems of high processing cost, complex structure of guide rail and guide seat, etc., and achieve low processing cost, light weight and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

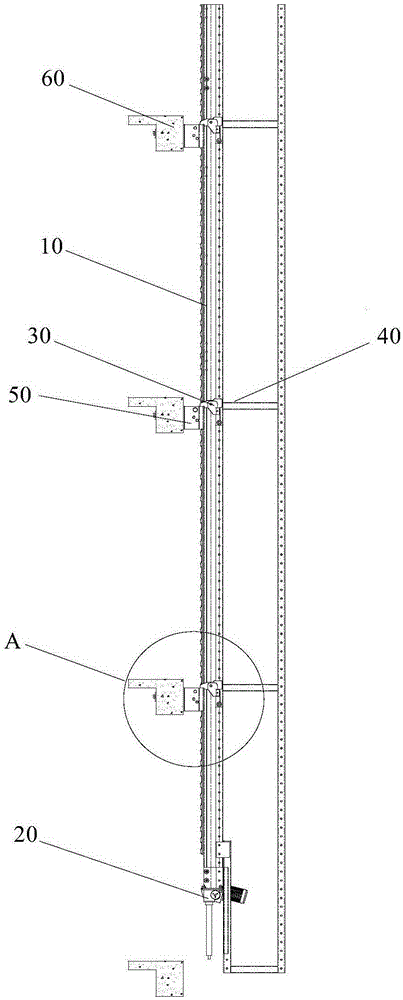

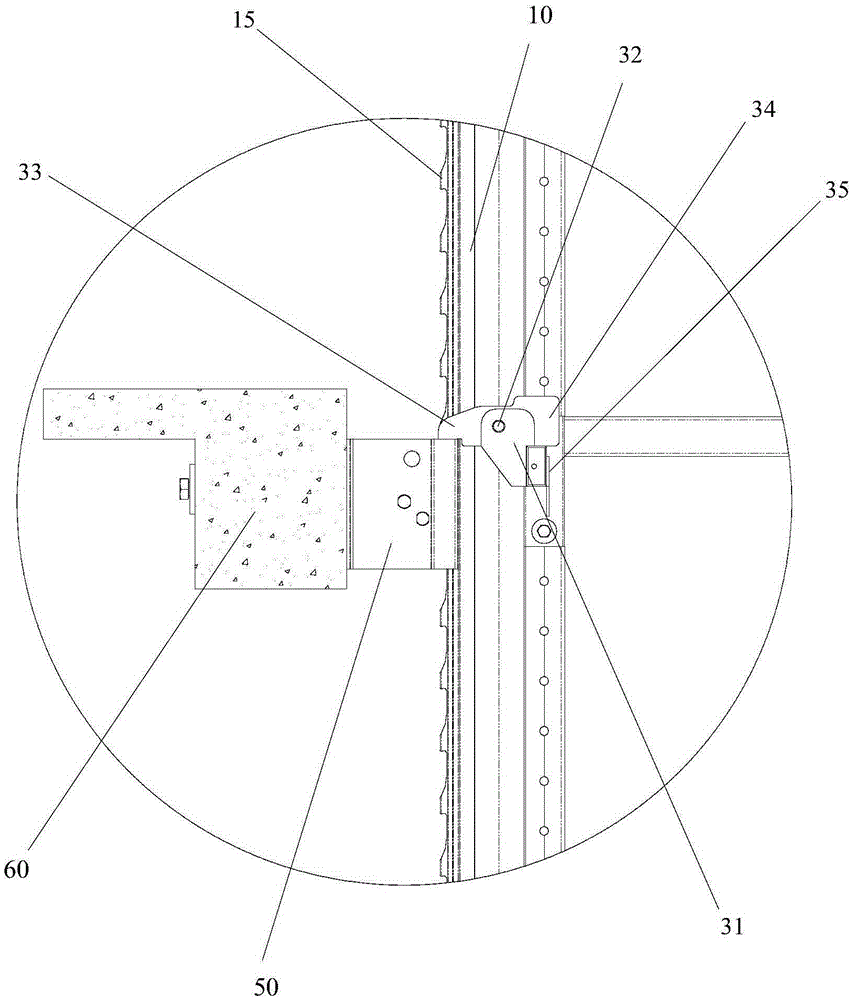

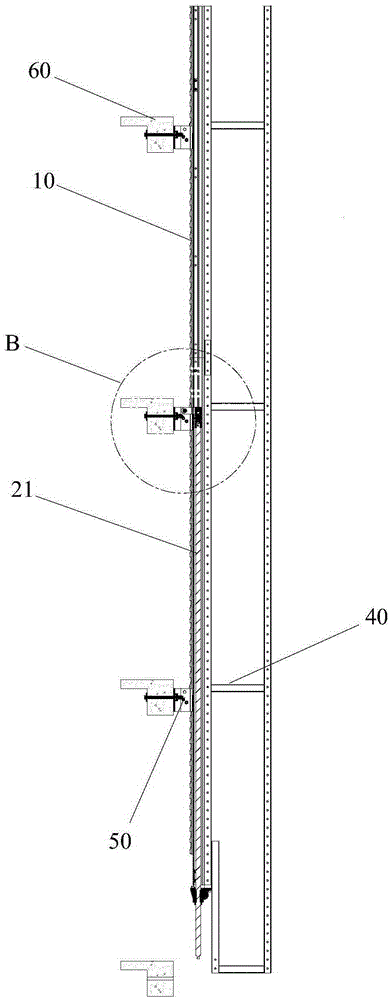

[0028] Such as Figure 1 to Figure 9 As shown, an embodiment of the construction safety screen of the present application includes a guide rail 10 , a lifting mechanism 20 , a positioning mechanism 30 , a scaffolding plate 40 and a guide seat 50 . The guide seat 50 is fixed on the building 60. In one embodiment, the guide seat 50 can be fixed on the building 60 through the wall screw 61. The protective net 40 is arranged on the guide rail 10, and the fall arrester is arranged on the guide seat 50. Above, the lifting mechanism 20 is used to drive the guide rail 10 to move up and down along the guide seat 50, and the positioning mechanism 30 is used to lock the guide rail 10 when the guide rail 10 stops moving. The guide seat 50 includes a bottom plate 51 , a side plate 52 and a slide groove 53 , the side plate 52 extends from tw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap