Integral stair formwork structure and construction method thereof

A technology of stairs and formwork, which is applied to the overall staircase formwork structure and its construction, can solve the problems of labor-intensive assembly and reinforcement, affecting the overall quality of the stairs, and large step errors of the stairs, so as to save turnover materials, reduce construction costs, and reduce turnover The effect of many times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

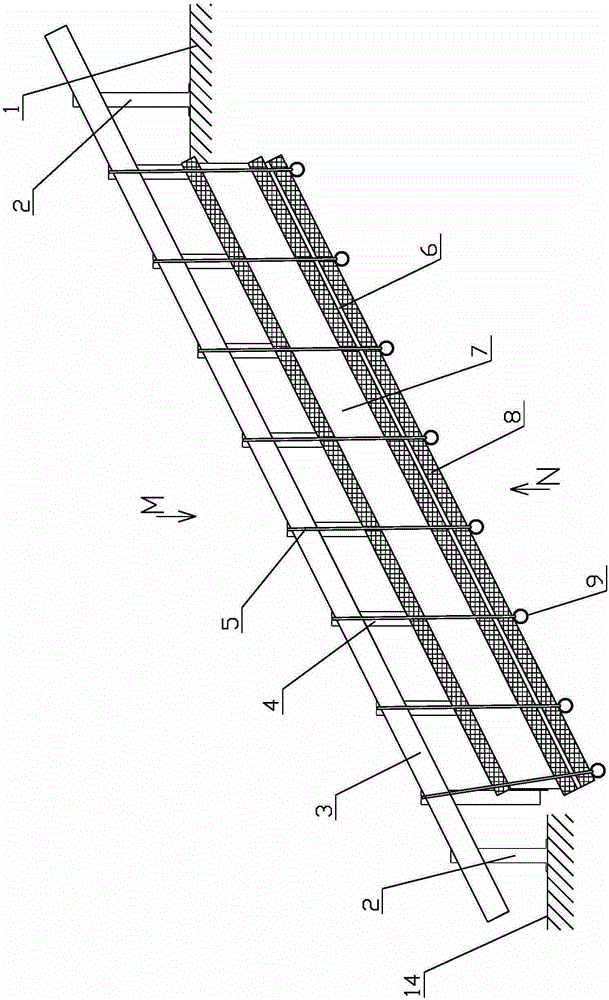

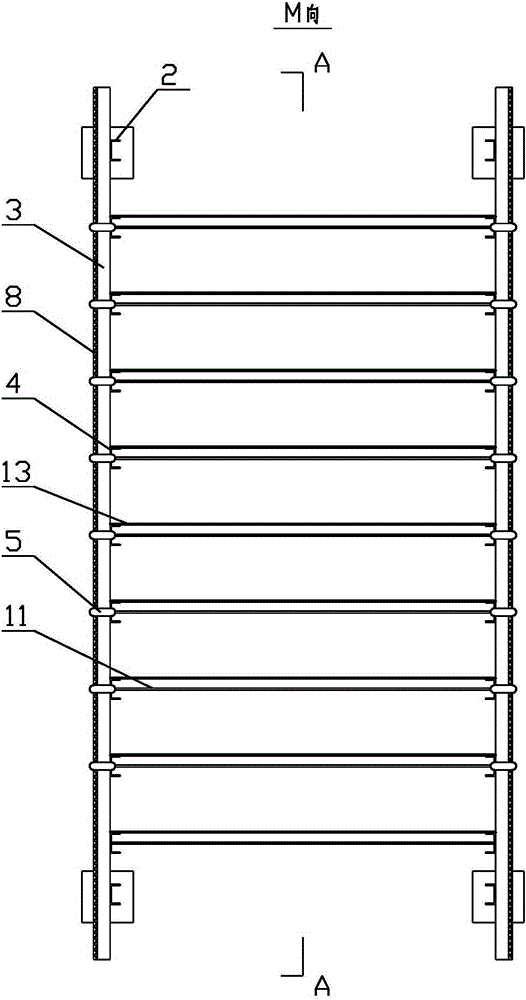

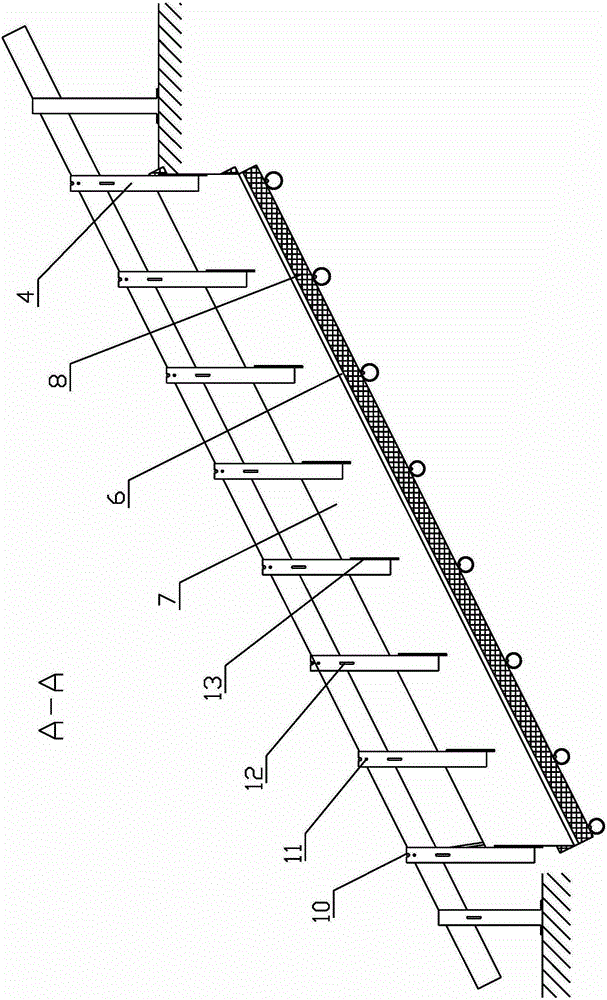

[0032] See Figure 1-Figure 4 , is a schematic structural view of the overall floor structure of the present invention, an integral staircase formwork structure of the present invention, including support 2, support beam 3, formwork support 4, staircase bottom formwork 6, staircase side formwork 7, step formwork 13 and pendant, described support beam 3 is 2 parallel settings, and its slope is consistent with the gradient of stairs, and support beam 3 two ends are respectively fixed on two-layer slow-walk platform 1,14 by bearing 2 to form support frame body; The support beam 3 is provided with a formwork support 4 at the position corresponding to the stepping position in the longitudinal direction, and the formwork assembly after the stair bottom mold 6 and the stair side formwork 7 are paired is suspended on the formwork support 4 through a penda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com