Integrally jointed container house

A container house, splicing technology, applied in small buildings, building components, thermal insulation, etc., can solve the problems of poor heat insulation and fire prevention performance, poor resistance to wind and rain, comfort discount, etc., to achieve structural stability and simplify the assembly process , The effect of being convenient for splicing and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

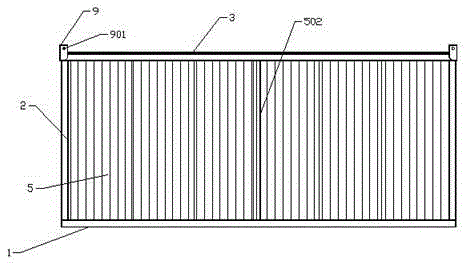

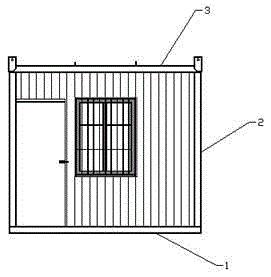

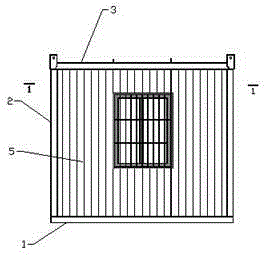

[0034] Please refer to the attached Figure 1 to Figure 5 , the container provided by the present invention includes a bottom frame 1, uprights 2 installed at the four corners of the bottom frame, and top struts 3 installed at the top of the uprights; A floor is installed on the bottom frame 1, a side plate 5 is installed between two adjacent columns 2, and a roof 6 is installed on the top pole 3. A door and a window are provided on the side plate for entering and exiting, ventilation and daylighting, and multiple windows can be opened. In the figure, the windows are respectively opened on the side plate 5 on one side of the door and on the other side side plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com