Compressed air energy storage power generation system

A compressed air energy storage and power generation system technology, applied in the electric power field, can solve problems such as insufficient combustion of fuel and air, low combustion efficiency, and flame deflection, and achieve the effects of suitable promotion and use, simplified equipment, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

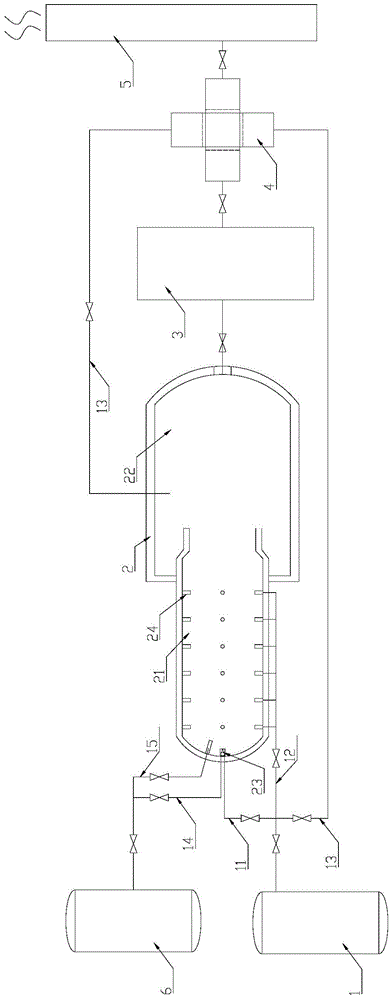

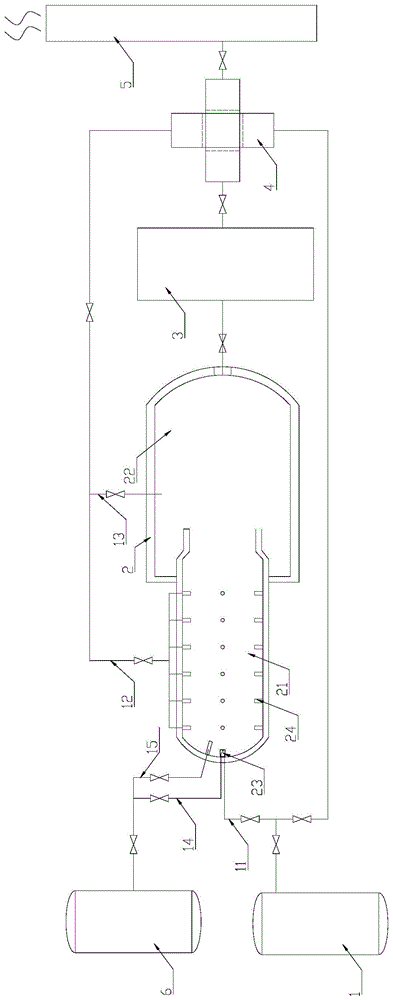

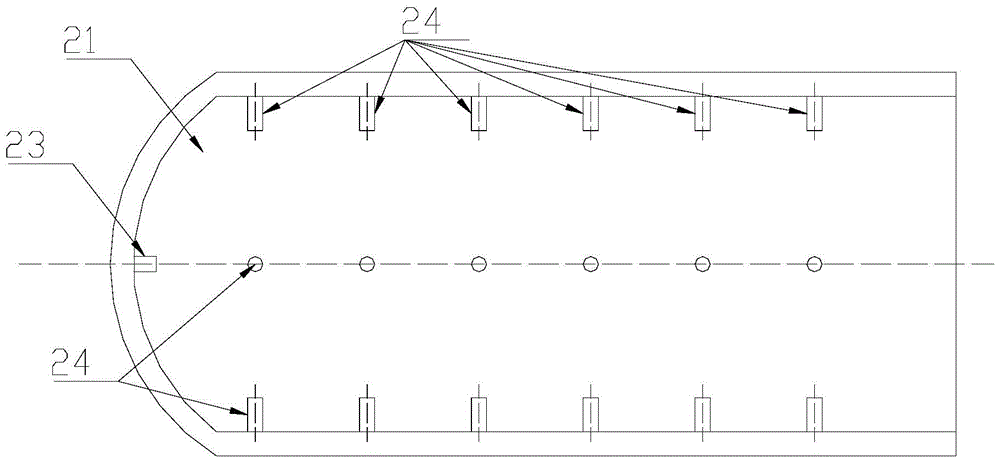

[0076] Such as figure 1As shown, in this embodiment, the compressed air energy storage power generation system further includes an air preheater 4 . The air preheater 4 includes two independent passages capable of heat exchange, a first passage 41 and a second passage 42 . The two ends of the first passage 41 communicate with the air outlet of the storage tank 1 and the air inlet nozzle 23 of the air heater 2 respectively, so that the air heated by the air heater 2 flows through the first passage 41 first; The second channel 42 is connected with the exhaust port of the power generation equipment and the air inlet of the exhaust cylinder 5 respectively, so that the gas with a certain temperature after the power generation operation is completed flows in the second channel 42 . Since the first channel 41 and the second channel 42 are in contact, the gas in the first channel 41 and the second channel 42 can conduct heat exchange, so that the generated gas exchanges heat with the...

Embodiment 2

[0081] Such as Figure 9 to Figure 13 As shown, in this embodiment, the air preheater 4 includes a heat exchange structure 410 composed of a plurality of plates 40 stacked with a certain gap; the opposite sides of each plate 40 are bent upwards , cooperate with the upper plate 40 to form a channel for gas to flow through; the adjacent plates 40 are alternately arranged vertically and horizontally, forming a first channel 41 arranged horizontally and a second channel 42 arranged vertically.

[0082] Such as Figure 11 As shown, each plate 40 is a rectangular plate of the same shape; each plate 40 includes a pair of lateral sides 43 and a pair of vertical sides 44 respectively; the lateral sides 43 and vertical sides of adjacent plates 40 44 alternate upward bending. The upper end of the upwardly bent side of each plate 40 is respectively in contact with the bottom surface of the upper plate 40 and fixed by welding. The gap distance between adjacent boards 40 is not greater t...

Embodiment 3

[0092] Such as Figure 18 As shown, in this embodiment, the air preheater 4 includes two channels that are independent of each other and capable of heat exchange, and the two ends of the first channel 41 communicate with the air supply equipment and the air heater inlet respectively. ; Both ends of the second channel 42 are respectively connected with the solar collector 7 to form a circulation channel for the molten salt medium to flow.

[0093] The two ends of the second channel 42 communicate with the outlet of the solar heat collector 7 through the liquid inlet pipeline respectively, and communicate with the inlet of the solar heat collector 7 through the liquid outlet pipeline; The liquid pipelines are respectively provided with control valves for controlling the passages of the pipelines.

[0094] preferred, such as Figure 18 As shown, in this embodiment, a two-position three-way valve 9 is provided on the liquid inlet pipeline, and the three openings of the two-posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com