Mixers and their mixing components

A technology of mixers and inclined parts, applied in the direction of engine components, machines/engines, noise reduction devices, etc., to achieve smooth passage, reduce the risk of liquid film formation, and reduce the effect of backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

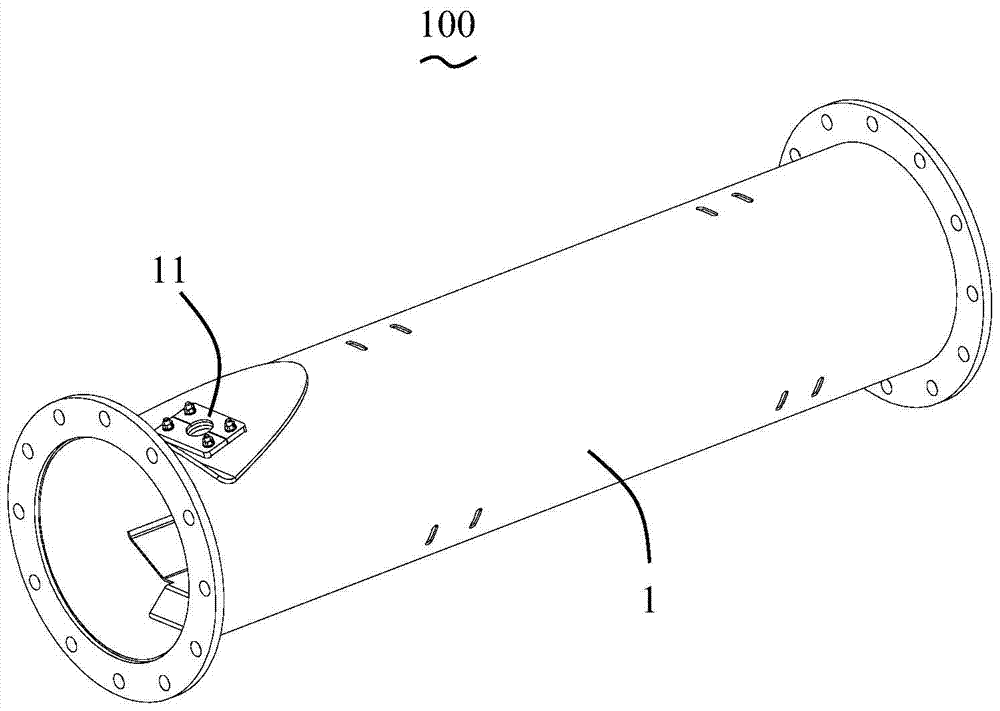

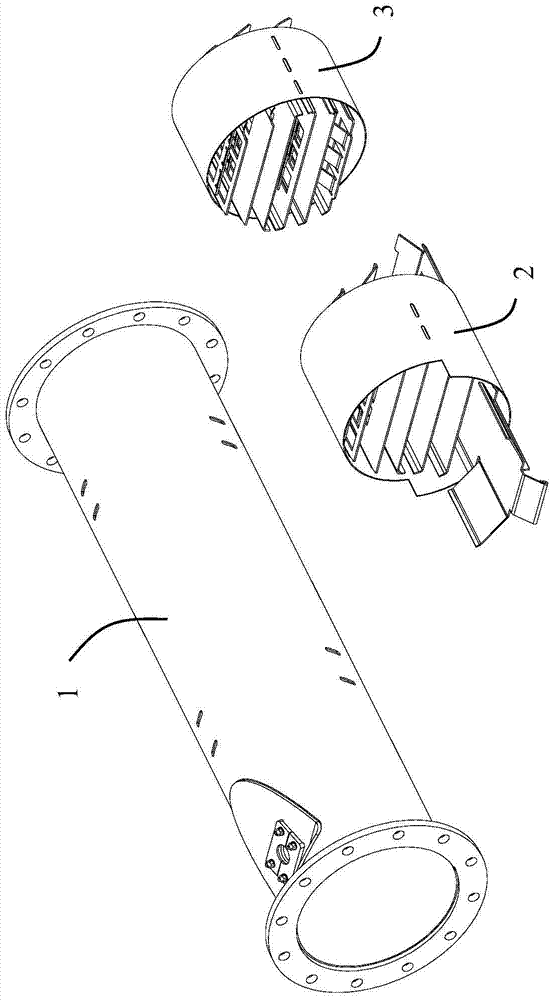

[0048] Please refer to Figure 1 to Figure 3 As shown, the present invention discloses a mixing assembly 100 , which includes a mixing tube 1 , a mixer 2 inside the mixing tube 1 , and a mixing element inside the mixing tube 1 and downstream of the mixer 2 . Please refer to figure 2 and image 3 As shown, in the first embodiment of the invention, the mixing element is a further mixer 3 . The mixing pipe 1 is provided with a urea nozzle installation part 11 for installing a urea nozzle (not shown), and the mixer 2 and another mixer 3 are located downstream of the urea nozzle installation part 11 . It can be understood that when the mixing assembly 100 of the present invention is installed in an exhaust gas after-treatment system, an oxidation catalyst (DOC) and / or a diesel particulate filter (DPF) may be provided upstream of the mixing assembly 100 , a selective catalytic reduction (SCR) may be provided downstream of the mixing assembly 100 .

[0049] When working, the ure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com