A sheathing device for a prestressed steel cylinder reinforced concrete pipe jacking joint

A technology of reinforced concrete and pipe jacking interface, applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc. To achieve the effect of simple construction and installation, perfect interface structure and reliable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

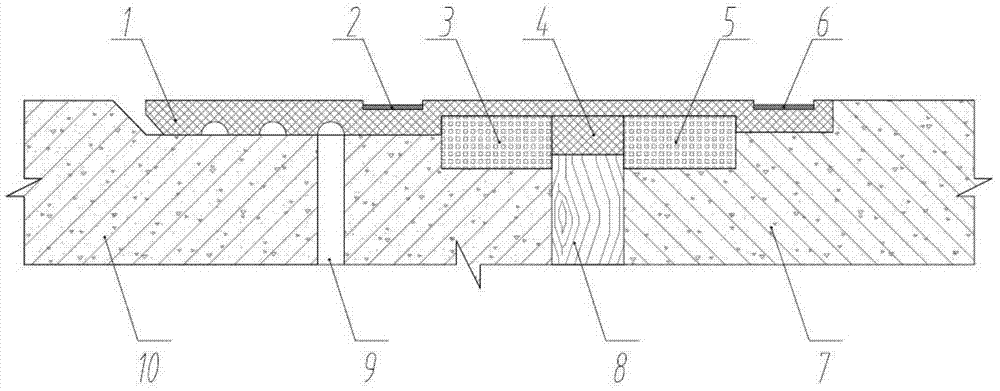

[0016] The present invention will be further described now in conjunction with accompanying drawing.

[0017] see figure 1 , the present invention is a sheathing device for a prestressed steel cylinder reinforced concrete pipe jacking joint, comprising a socket, a socket, a joint sealant and a pine board. The joints of the socket steel sleeve 10 and the socket steel sleeve 7 are provided with multi-layer or pine boards 8, and the ends of the multi-layer or pine boards 8 are filled with interface sealant 4, and the interface sealant 4 is located on the socket steel ring 5 Between the socket steel ring 3, a rubber sheath 1 is set on the outer wall of the joint between the socket steel sleeve 10 and the socket steel sleeve 7, and the end of the rubber sheath 1 extends and covers the grouting pipe 9 On the spout, the end of the rubber sheath 1 is provided with an annular groove, and the annular groove matches the position of the spout of the grouting pipe 9 . The annular groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com