Flat-base concave screw thread connecting piece

A connector and concave technology, applied in the field of flat-bottomed concave plug connectors

Inactive Publication Date: 2016-02-03

杨宴敏

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002]Current plugs have poor chemical resistance, are highly corroded by sewage and wastewater, and are corroded by soil rot substances. Frost cracking and swelling and water leakage can not adapt to different equipment specifications, and the safety is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

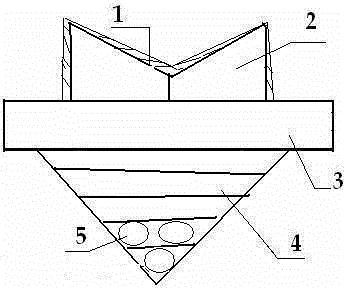

[0012] see figure 1 As shown, the present invention includes a groove and a brim, the groove is located at the top, and a prism structure is arranged below the groove, and the prism structure is integrally cast with the groove, and the brim is cast on the prism Below the structure, below the prism structure, there is a flat bottom buckle, and a polishing material is provided on the surface of the groove.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a flat-base concave screw thread connecting piece. The connecting piece comprises a groove and a brim. The groove is located at the topmost end, and an edge structure is arranged below the groove; the edge structure and the groove are cast into a whole; the brim is cast below the edge structure, and a flat base buckle is arranged below the edge structure; and a polishing material is arranged on the surface of the groove.

Description

technical field [0001] The invention belongs to the field of manufacturing technology, and in particular relates to a flat-bottomed concave plug connector. Background technique [0002] The current plugs have poor chemical resistance, are highly corroded by sewage and waste water, and are corroded by soil rotten substances. In the ultra-low temperature environment of minus 60°C, there are phenomena of freezing cracks, swelling and water leakage, and cannot adapt to different equipment specifications. Safety Sex is poor. Contents of the invention [0003] The invention overcomes the shortcomings of the prior art and proposes a flat-bottomed concave plug connector. . , the structure design is exquisite, unique technology, fine processing, energy saving and noise reduction, safety and environmental protection, and reduce labor intensity. [0004] The technical solution of the present invention is: a flat-bottomed concave plug connector, including a groove and a brim, the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L55/10

Inventor 杨宴敏

Owner 杨宴敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com