Novel efficient energy-saving superheat boiler

A superheated boiler, high-efficiency and energy-saving technology, applied in the directions of steam superheating, lighting and heating equipment, steam generation, etc., can solve the problems of waste heat steam and low-temperature steam power and low power generation efficiency, reduce the latent heat of vaporization, and improve the power and power generation rate. , The effect of improving power and power generation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

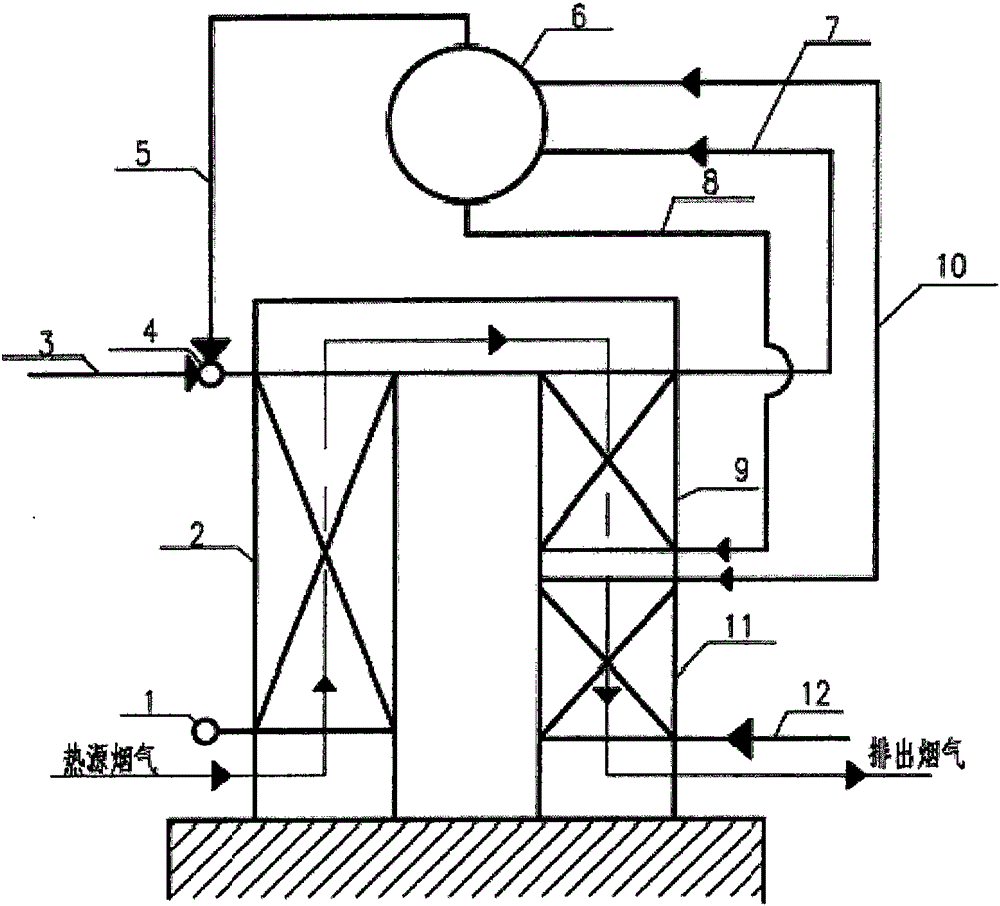

[0017] According to the attached figure 1 The present invention is further analyzed:

[0018] Such as figure 1 A new type of energy-saving superheated boiler is shown. The high-temperature heat source flue gas generated by boiler combustion or externally input is discharged from the tail of economizer 11 after heat exchange through superheater 2, evaporator 9 and economizer 11 in sequence; The input waste heat steam and low-temperature steam pass through the input waste heat steam and low-temperature steam pipe 4, and the saturated steam output from the drum 6 passes through the saturated steam pipe 5, and the above are jointly input into the superheater inlet header 3, and are transported to the superheater 2, and then passed through After the superhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com