Moving gantry type measuring system and method for vehicle-mounted material volume

A technology for volume measurement and materials, applied in volume measurement instruments/methods, liquid/fluid solid measurement, and measurement devices, can solve problems such as high cost, raw material doping, and impact on measurement accuracy, and achieve low cost, stable measurement, and The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

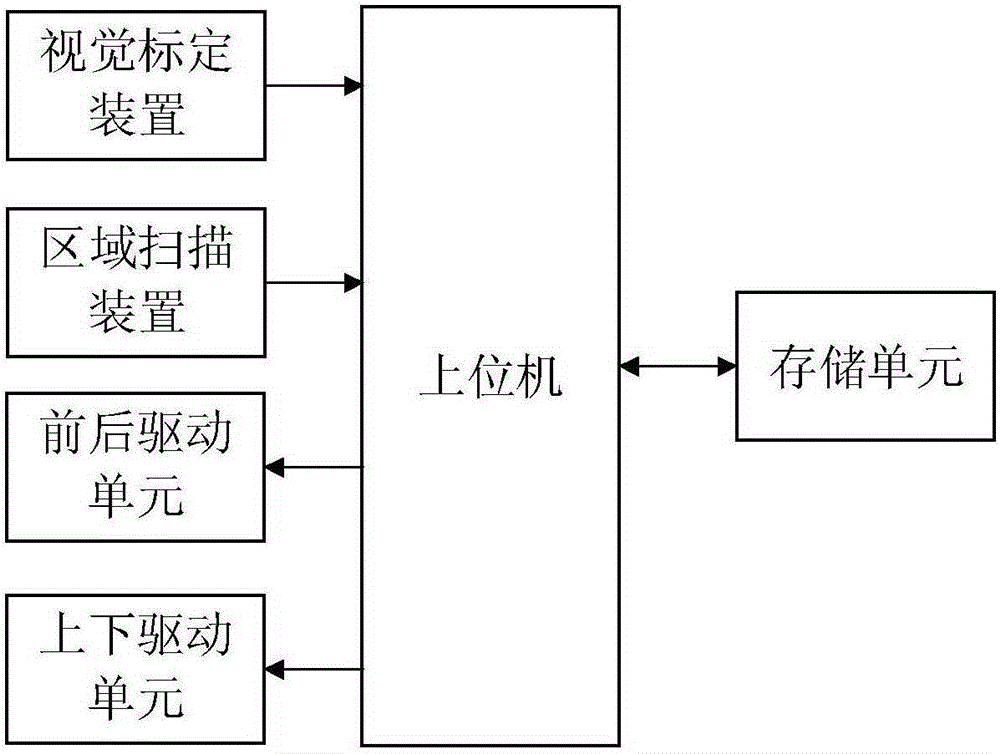

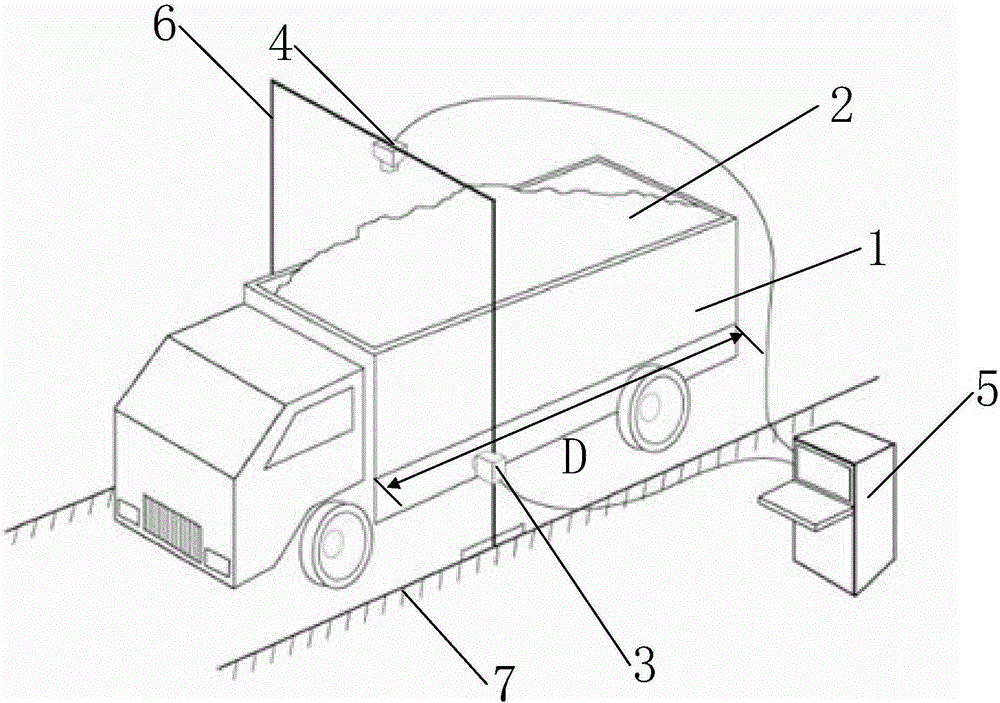

[0031] like figure 1 Shown, a kind of vehicle-mounted material volume measurement system of the present invention comprises:

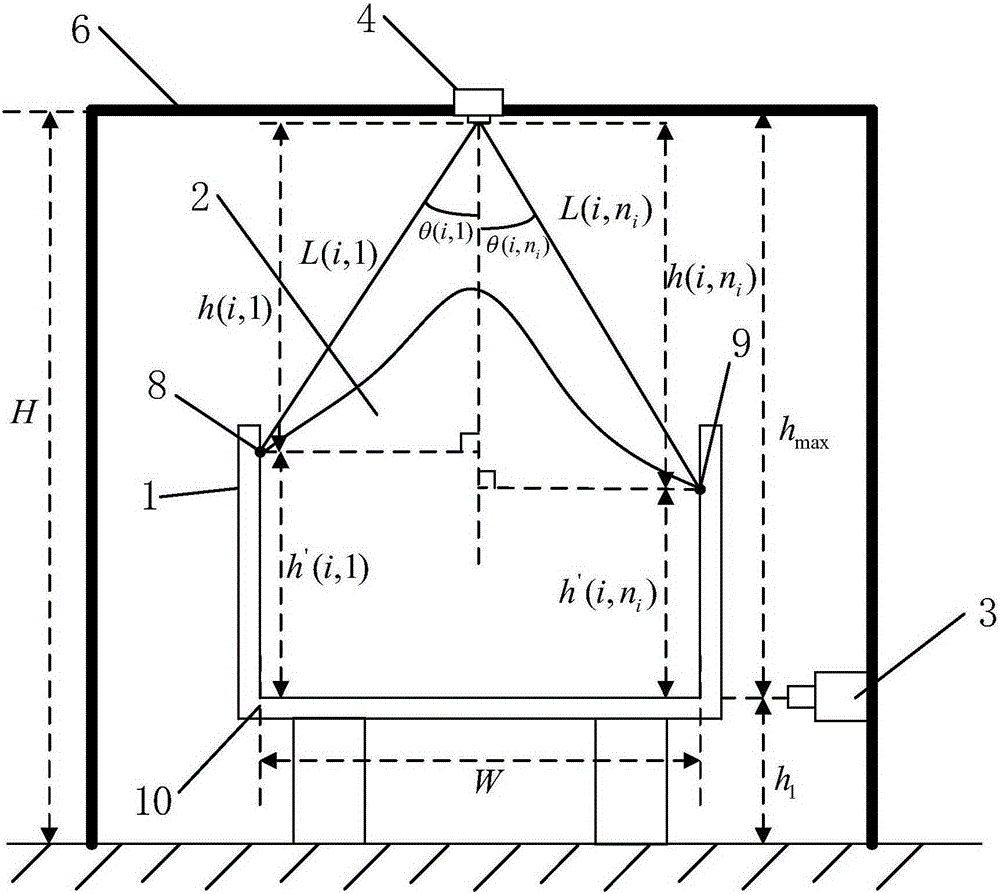

[0032] The visual calibration device 3 is used to calibrate the length D of the compartment 1 of the truck to be tested and the height h of the compartment floor 10 1 , the height h of the compartment floor 10 1 Specifically, it is the height between the compartment floor 10 and the ground.

[0033]The area scanning device 4 is located above the compartment 1 and scans the materials 2 in the compartment 1 vertically downward along the compartment 1 .

[0034] The upper computer 5 is connected with the visual marking device 3 and the area scanning device 4, and is suitable for scanning signals according to the area scanning device 4 and the height h of the compartment floor 1 Obtain the width W of compartment 1 and the average net height of material 2 And calculate the total volume V of the material 2 with the length D of the compartment 1.

[003...

Embodiment 2

[0042] On the basis of Embodiment 1, the present invention also provides a method for measuring the volume of vehicle-mounted materials, comprising the following steps:

[0043] Step S1, obtain the length D of compartment 1 and the height h of the compartment floor 1 ; Step S2, scanning the material 2 in the compartment 1 vertically downwards along the compartment 1 through the area scanning device 4 located above the compartment 1 and according to the height h of the compartment floor 1 , to obtain the width W of compartment 1 and the average net height of material 2 And step S3, the width W of compartment 1, the average net height of material 2 Calculate the total volume V of the material 2 with the length D of the compartment 1.

[0044] Preferably, the vehicle-mounted material volume measurement method adopts a vehicle-mounted material volume measurement system to obtain the total volume of the material 2; the vehicle-mounted material volume measurement system includes...

Embodiment 3

[0056] On the basis of Embodiment 1 and Embodiment 2, the vehicle-mounted material volume measurement system and method are described in detail.

[0057] In this vehicle-mounted material volume measurement system, the area scanning device 4 (for example, adopting a laser area scanning sensor) and the digital camera are connected with the Ethernet port and the USB interface of the host computer 5 respectively, and the PLC in the control cabinet (for controlling the upper and lower drive units, the front and rear drives) unit, the described up and down drive unit and front and rear drive unit are not limited to known methods such as screw mandrel and guide rail, etc.), and the PLC can communicate with the upper computer 5 through RS232. The size of the gantry 6 is for example but not limited to: the height is 4.5m, the width is 3.5m, the length of the horizontal guide rail 7 is 10m, the initial position of the digital camera is 0.5m from the ground height, and the digital camera ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com