Device and method for liquid level height measurement of continuous casting tundish

A technology of continuous casting tundish and liquid level, which is applied in the direction of buoy liquid level indicator, etc., can solve the problems of difficulty in measuring the liquid level of molten steel in the tundish and low accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

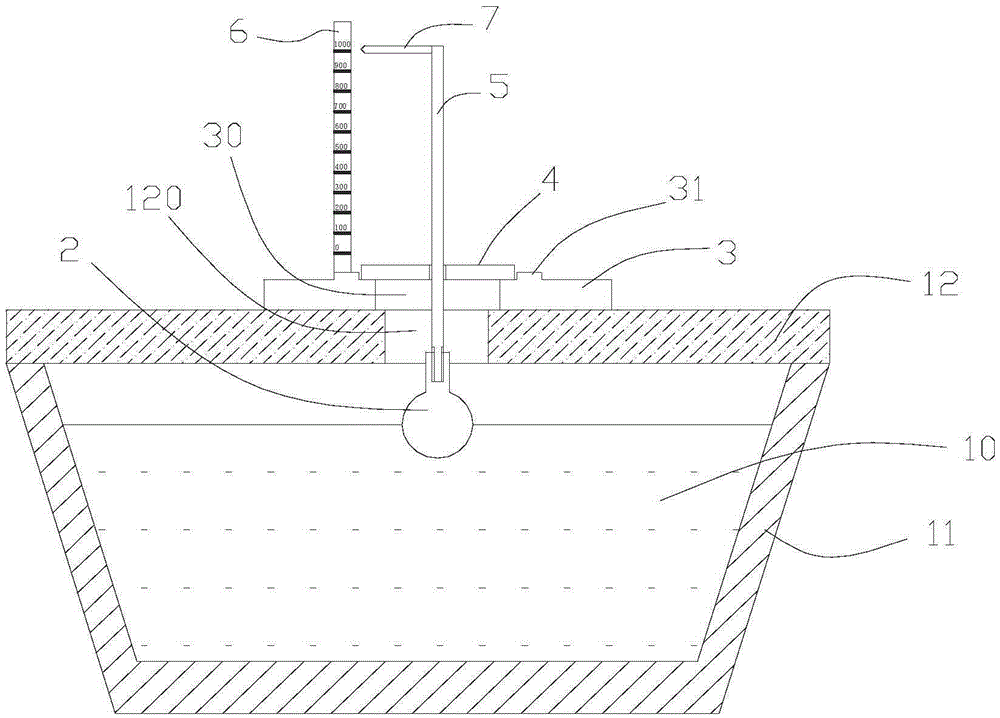

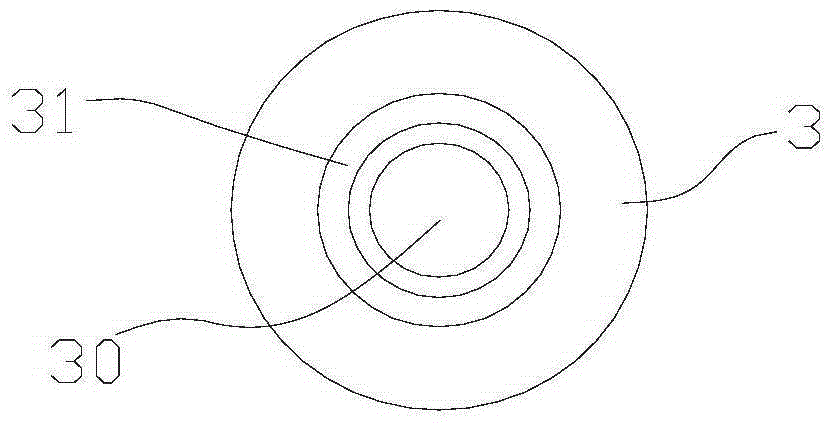

[0025] Such as figure 1 As shown, the embodiment of the present invention includes a float 2 , a tray 3 , a positioning plate 4 , a pole 5 , a ruler 6 , and a pointer 7 . In order to describe the mechanism of this embodiment more clearly, figure 1 It also shows the cooperative relationship between this embodiment and the tundish 11 in application, and shows the molten steel 10 in the tundish 11 .

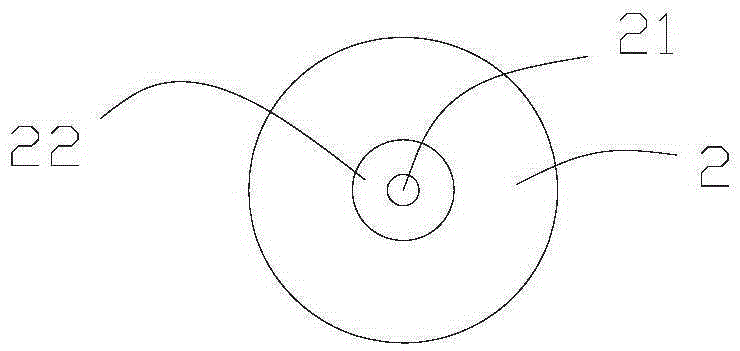

[0026] Specifically, the floating ball 2 is in the shape of a ball, and is used for placing and floating on the surface of the molten steel 10 in the tundish 11 . Preferably, the floating ball 2 is made of corundum or graphite carbon refractory material, and is pressed into shape by using such material through a pressing process. In order to realize the fast connection between the floating ball 2 and the benchmark 5, the floating ball 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com