Safety monitoring system for programmable logic controller in industrial control system and method thereof

A technology of industrial control system and safety monitoring system, which is applied in the direction of program control in sequence/logic controller, general control system, control/regulation system, etc., and can solve the problem of tampering and the lack of security solutions for lower computer programmable logic controllers , On-site device status information is unreliable, etc., to achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments of the description

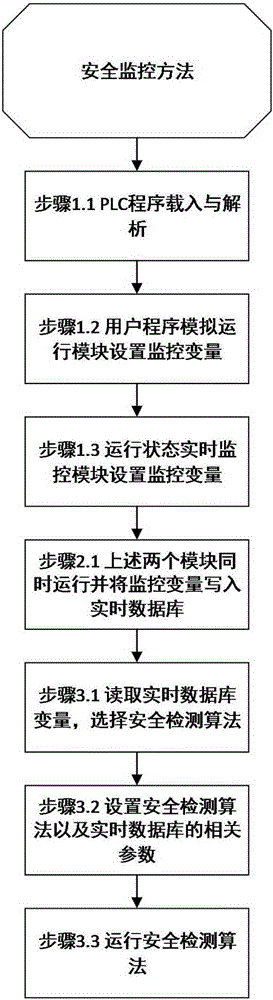

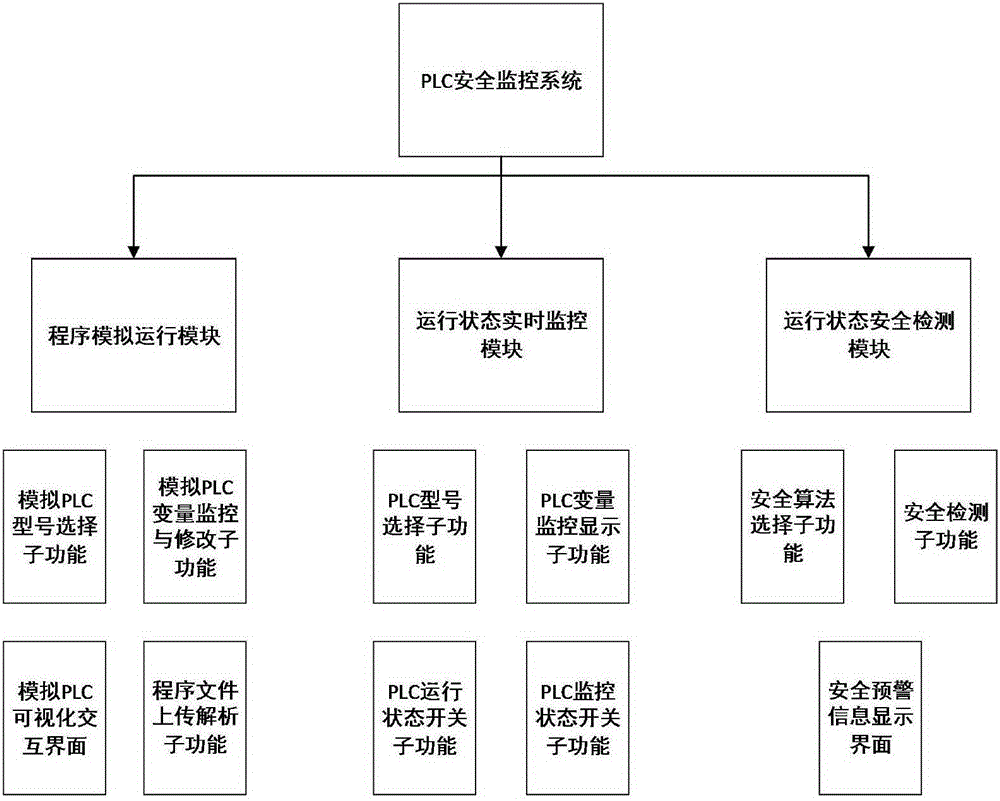

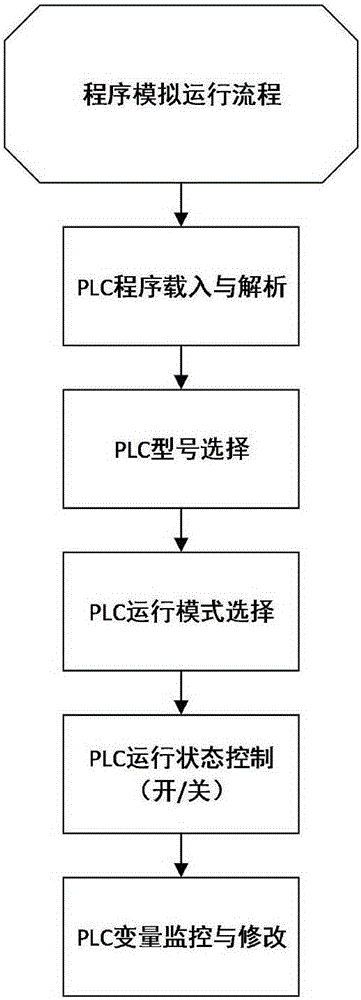

[0054] figure 2 It describes the structure diagram of the PLC safety monitoring system, including three modules: user program simulation operation module, real-time monitoring module of running status and safety detection module of running status. Among the three modules, the user program simulation running module and the running status real-time monitoring module can run independently, and the running status safety detection module must use the output of the first two modules as input to get the correct result. Below the present invention will do the elaboration of specific implementation mode with Siemens S7-200 series PLC, simplify flow process as Figure 3.1-3.3 shown.

[0055] The main function of the user program simulation operation module described here is to read in the AWL file exported by the STEP7 prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com