Composition comprising silylated polymers

一种甲硅烷基化、组合物的技术,应用在聚脲/聚氨酯粘合剂、粘合剂类型、聚脲/聚氨酯涂料等方向,能够解决锡水平过高、聚合物变色、未证明等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

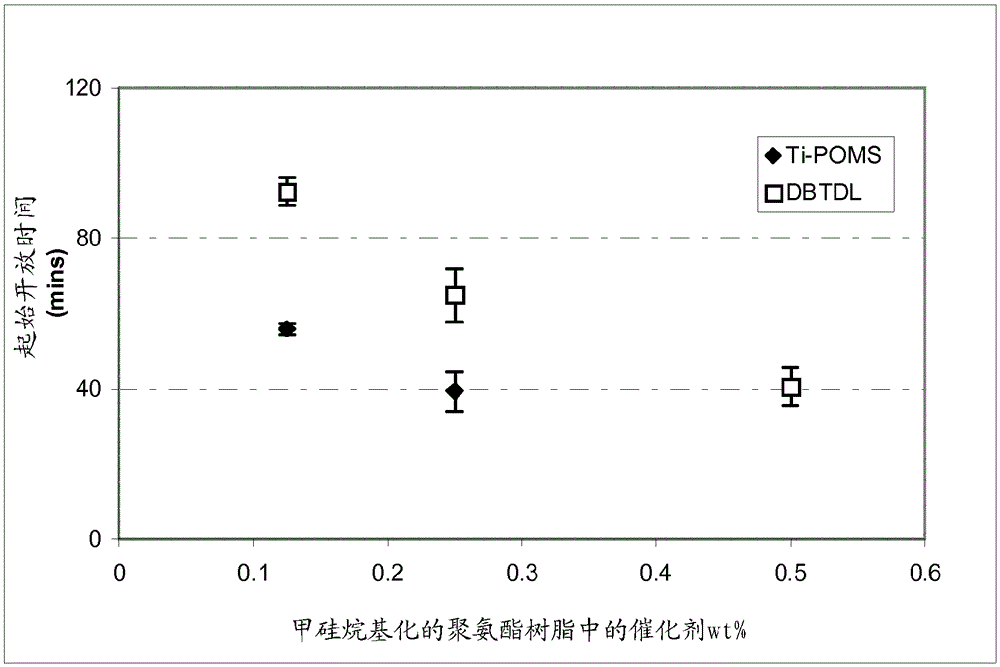

[0190] Example 1 (according to the invention)

[0191] Isobutyl POMS titanium isopropoxide in DINP (orthophthalene di 2.7 wt% solution in di-isononyl formate). This solution was formulated with silylated polyurethane resin 1. The solution contained 91.3 wt% silylated polyurethane resin and 8.7 wt% isobutyl POMS titanium isopropoxide solution. The mixture was flushed with nitrogen and mixed for 5 minutes at 2500 rpm. The final content of isobutyl POMS titanium isopropoxide in the silylated polyurethane resin was 0.23 wt% (0.012 wt% Ti). Casting at 500 microns was performed and cure characteristics studied with a BK dryer recorder.

[0192] Start Open Time: 42 minutes, and Scratch End Time: 110 minutes.

Embodiment 2

[0193] Example 2 (Comparative example - Sn cured silylated polyurethane resin)

[0194] The mixture was prepared by shearing a 5.4 wt% mixture of dibutyltin dilaurate (DBTDL) and DINP (di-isononyl phthalate) at 2500 rpm for 5 minutes. This solution was formulated with a silylated polyurethane resin. The solution contained 91.3 wt% of silylated polyurethane resin 1 and 8.7 wt% of DBTDL solution. The mixture was flushed with nitrogen and mixed for 5 minutes at 2500 rpm. The final content of DBTDL in the silylated polyurethane resin was 0.47 wt% (0.087 wt% of Sn). Casting at 500 microns was performed and cure characteristics studied with a BK dryer recorder.

[0195] Start Open Time: 41 minutes, Scratch End Time: 105 minutes.

[0196] Examples 1 and 2 have shown that with half the amount of isobutyl POMS titanium isopropoxide added to the silylated polyurethane resin compared to DBDTL, or alternatively the amount of titanium isopropoxide added to the silylated polyurethane ...

Embodiment 3

[0197] Example 3 (according to the invention)

[0198] A 3.3 wt% solution of this catalyst in toluene was prepared by dissolving isobutyl POMS titanium isopropoxide in the solvent in an ultrasonic bath for 30 minutes at RT, followed by mixing at 2500 rpm for 6 minutes. This solution was formulated with silylated polyurethane resin 1. The solution contained 94.1 wt% silylated polyurethane resin and 6.9 wt% isobutyl POMS titanium isopropoxide. The mixture was flushed with nitrogen and mixed for 5 minutes at 2500 rpm. The final content of isobutyl POMS titanium isopropoxide in the silylated polyurethane resin was 0.23 wt%. Casting at 500 microns was performed and cure characteristics studied with a BK dryer recorder.

[0199] Start Open Time: 43 minutes, Scratch End Time: 115 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com