Vacuum electromagnetic betel nut impregnation system

A vacuum system and electromagnetic system technology, applied in food processing, application, food preparation, etc., can solve the problems of insufficient contact between betel nut and hair seed liquid, inability to satisfy the taste of betel nut seeds, weak expansion of betel nut, etc., and achieve reduction The risk of microbial reproduction, shortening the time of seed germination, and the effect of improving hygiene indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

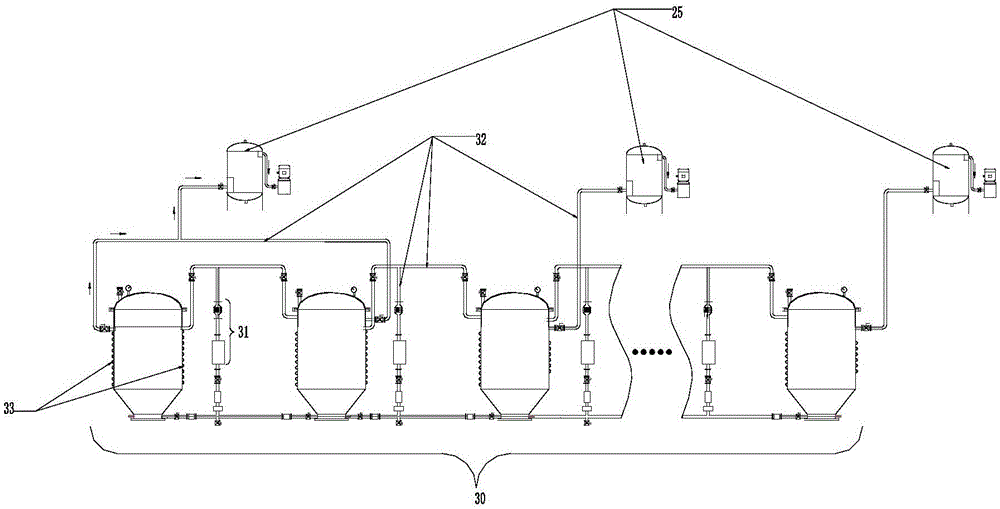

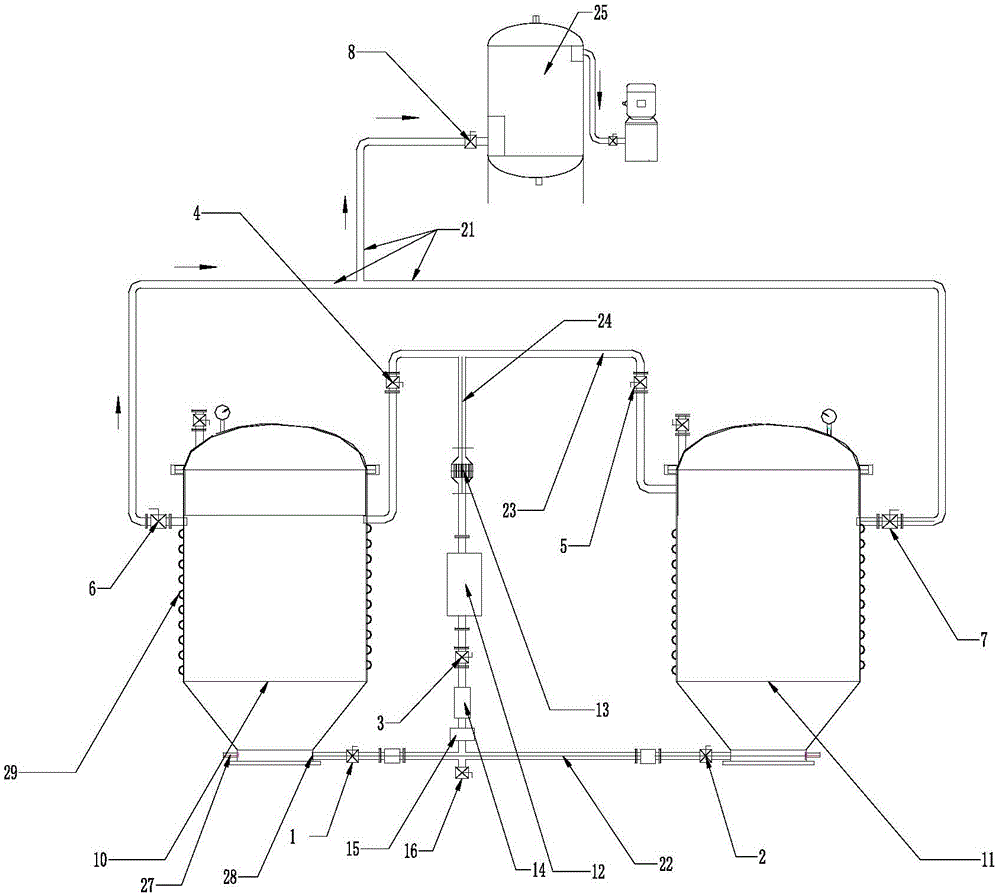

[0030] Areca nut vacuum electromagnetic seeding system, such as figure 1 As shown, it includes a vacuum electromagnetic seed tank group 30, a pipeline system 32, a vacuum system 25, an emulsification system 31, and an electromagnetic system 33. Such as figure 2 As shown, the pipeline system 32 includes an upper circulation pipeline 23 , a lower circulation pipeline 22 , a liquid return pipe 24 and a vacuum pipe 21 . The top of each vacuum electromagnetic seeding tank in the vacuum electromagnetic seeding tank group 30 is connected with the upper circulation pipeline 23, and the bottom is connected with the lower circulation pipeline 22, and the upper circulation pipeline 23 and the lower circulation pipeline 22 are connected by a liquid return pipe 24. The vacuum electromagnetic seed jar top is connected with vacuum system 25 by vacuum tube 21. The liquid return pipe 24 is provided with an emulsification system 31 , a flow meter 14 and a filter 15 . The emulsification syst...

Embodiment 2

[0032] Areca nut vacuum electromagnetic seeding system, such as figure 1 As shown, it includes a vacuum electromagnetic seed tank group 30, a pipeline system 32, a vacuum system 25, an emulsification system 31, and an electromagnetic system 33. Such as figure 2 As shown, the vacuum electromagnetic seeding tank group 30 includes two vacuum electromagnetic seeding tanks, the first vacuum electromagnetic seeding tank 10 and the second vacuum electromagnetic seeding tank 11, and the upper parts of the two vacuum electromagnetic seeding tanks are connected by an upper circulation pipeline 23 The bottoms of the two vacuum electromagnetic seeding tanks are connected through the lower circulation pipeline 22, and the upper circulation pipeline 23 between the two vacuum electromagnetic seeding tanks is connected with the lower circulation pipeline 22 through the liquid return pipe 24. The upper circulation pipeline 23, the lower circulation pipeline 22, and the liquid return pipe 24 ...

Embodiment 3

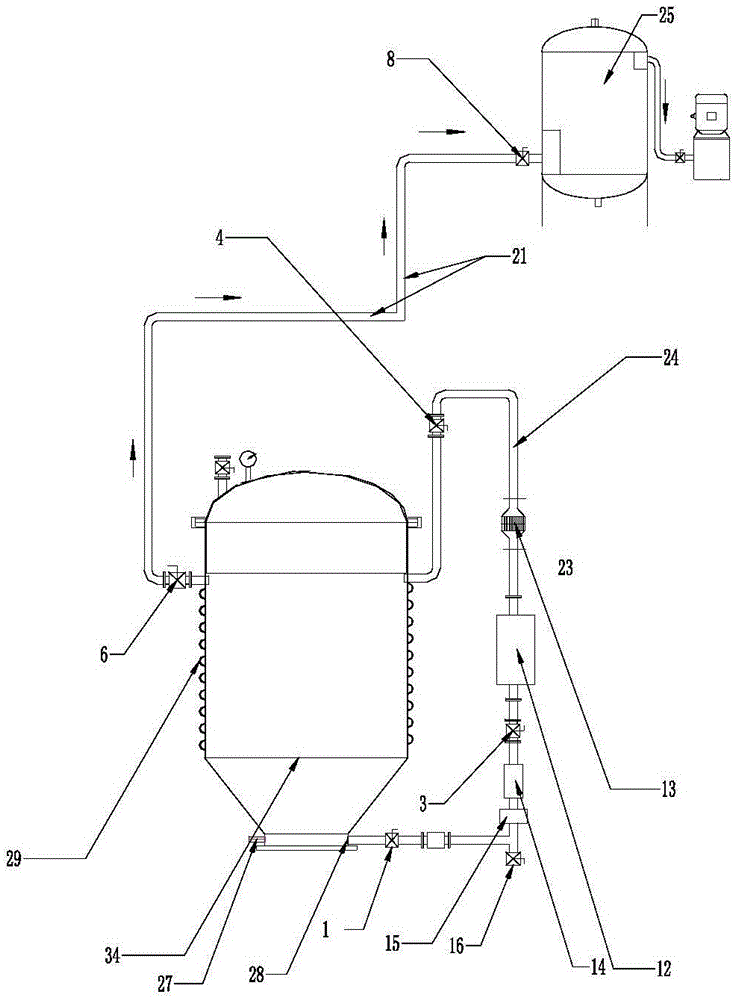

[0034] Areca nut vacuum electromagnetic seeding system, such as figure 1 As shown, it includes a vacuum electromagnetic seed tank group 30, a pipeline system 32, a vacuum system 25, an emulsification system 31, and an electromagnetic system 33. Such as image 3 As shown, the vacuum electromagnetic seeding tank group 30 is composed of a single vacuum electromagnetic seeding tank 34 . The top of the single vacuum electromagnetic seed tank 34 is connected with the upper circulation pipeline 23, the bottom of the single vacuum electromagnetic seed tank 34 is connected with the lower circulation pipeline 22, and the upper circulation pipeline 23 and the lower circulation pipeline 22 are connected by the liquid return pipe 24. The single vacuum electromagnetic seed tank 34 top is connected with the vacuum system 25 by the vacuum tube 21. Vacuum system 25 as Figure 5 As shown, it includes a vacuum buffer tank 17 and a vacuum pump 18. The vacuum pump 18 and the vacuum buffer tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com