Patents

Literature

33results about How to "Reduce the risk of breeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cottage breeding method of dendrobium officinale

InactiveCN101336589AReduce riskShorten the cultivation cycleCultivating equipmentsSoilless cultivationPotassium permanganateWoven fabric

The invention relates to a cuttage cultivation method of Dendrobium officinale. The method comprises the following steps: (1) cuttage material preparation: extracting the pseudobulb from the root of the parent plant and serving as the cuttage material; (2) cuttage material segmentation: cutting the pseudobulb into cutting shoots and allowing 2 to 3 nodes of each cutting shoot, cutting off leaves between the nodes, and soaking the cutting shoots in the potassium permanganate solution and then air-drying; (3) shoot cuttage: inserting the cutting shoots in a prepared cuttage matrix, watering and covering with a wet non-woven fabric; (4) cutting shoot management: keeping the cultivation environment semi-shady and moist, maintaining the temperature in the range from 5 DEG C to 35 DEG C and ensuring the illumination in the range from 1500 to 5000 lux; and (5) transplanting: cutting off the regenerated plant by using a pair of sterilized scissors and transplanting to a transplantation matrix. By adopting the cuttage cultivation method, the cultured plant retains the excellent quality of the parent plant and is free from mutation. The cuttage cultivation method has the advantages of foreseeable cultivation result, low cultivation risk and short cultivation period.

Owner:吴江市苗圃集团有限公司

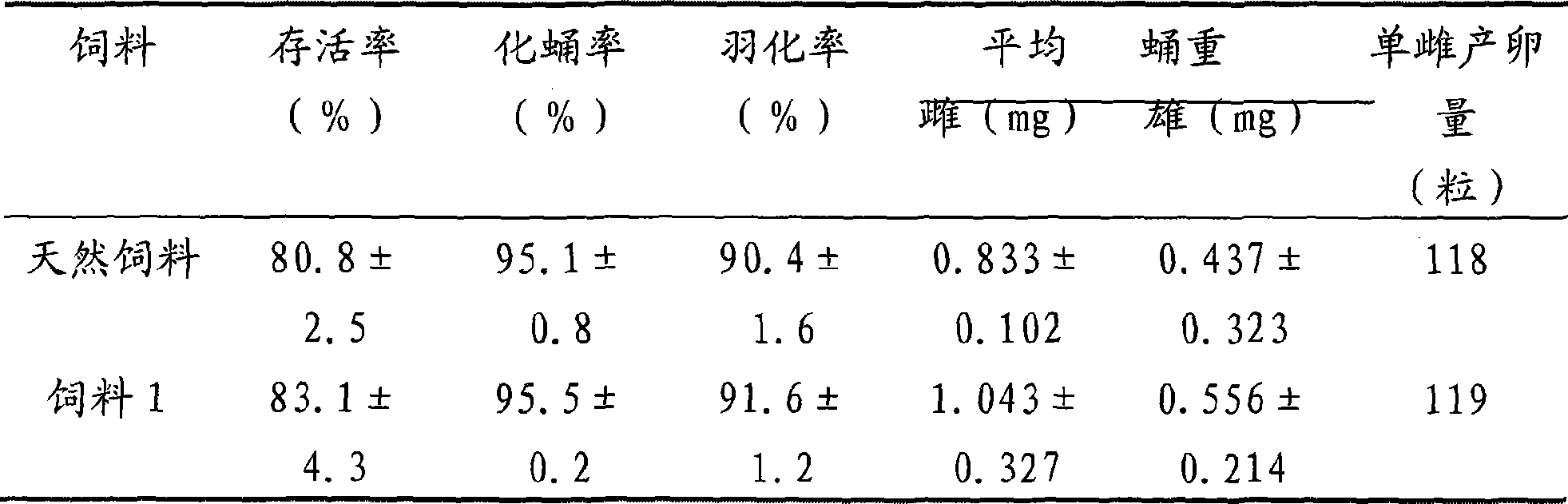

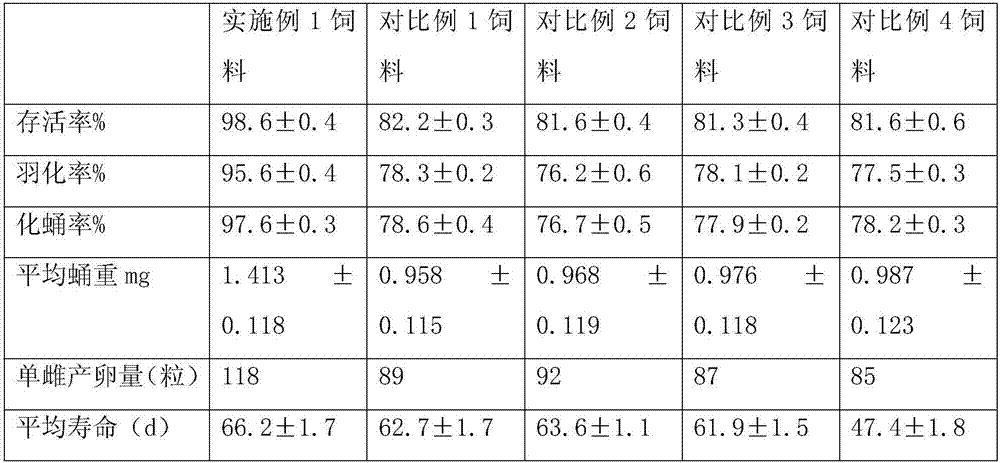

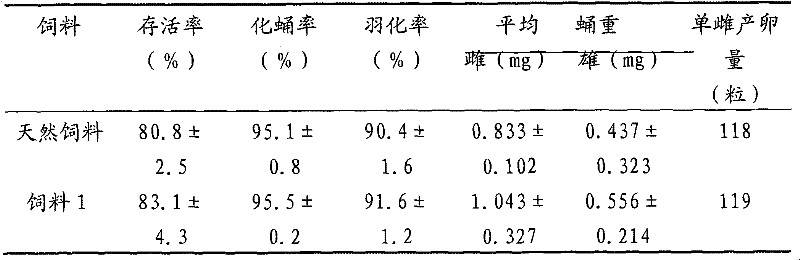

Artificial synthetic feed containing leek maggot

The invention relates to artificial synthetic feed, in particular to artificial synthetic feed of chive maggot. The feed consists of mushroom powder taken as a main composition and yeast powder as an auxiliary material. The feed with the mixture ratio is used to feed the chive maggot; the survival rate, the pupation rate, the eclosion rate and the egg laying amount of a single female are quite close to the chive maggot fed by natural feed; and the average pupae weight of male and female is higher than the chive maggot fed by natural feed, thereby favorable condition for normal supply for the tested chive maggot.

Owner:INST OF PLANT PROTECTION SHANDONG ACAD OF AGRI SCI

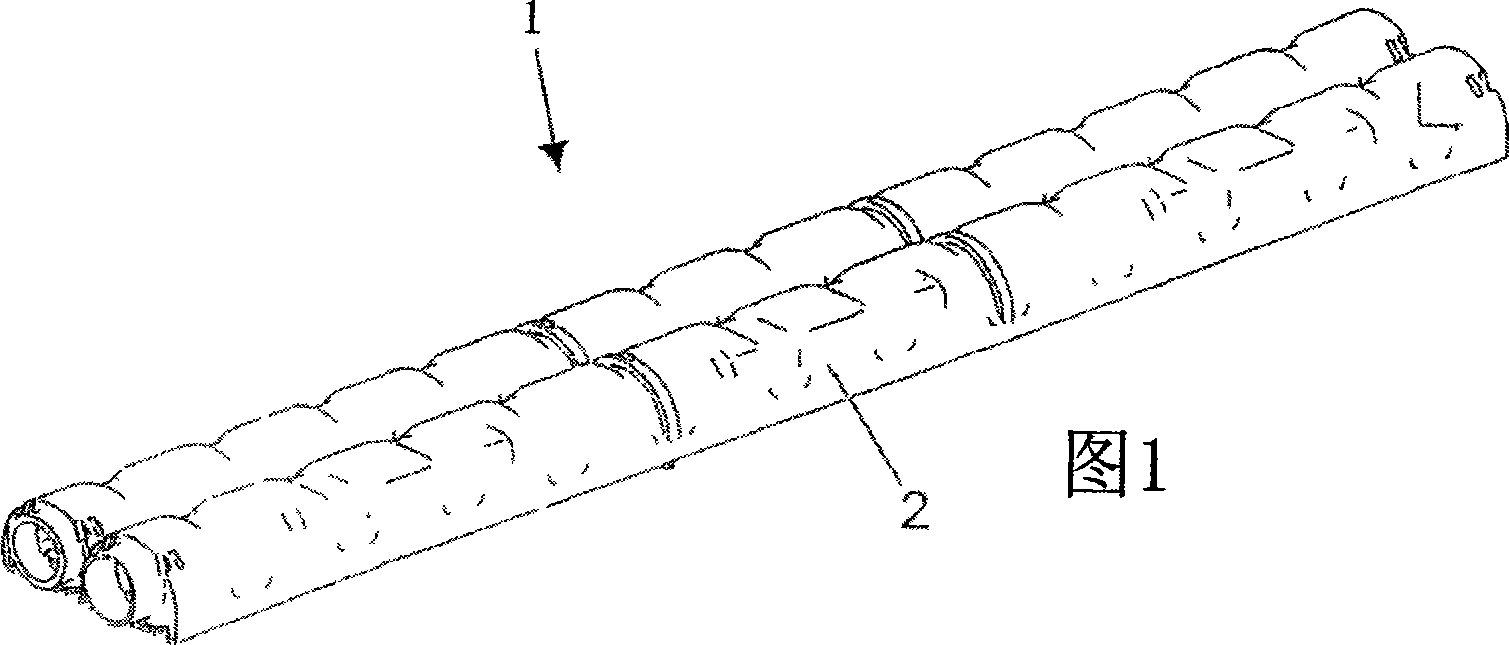

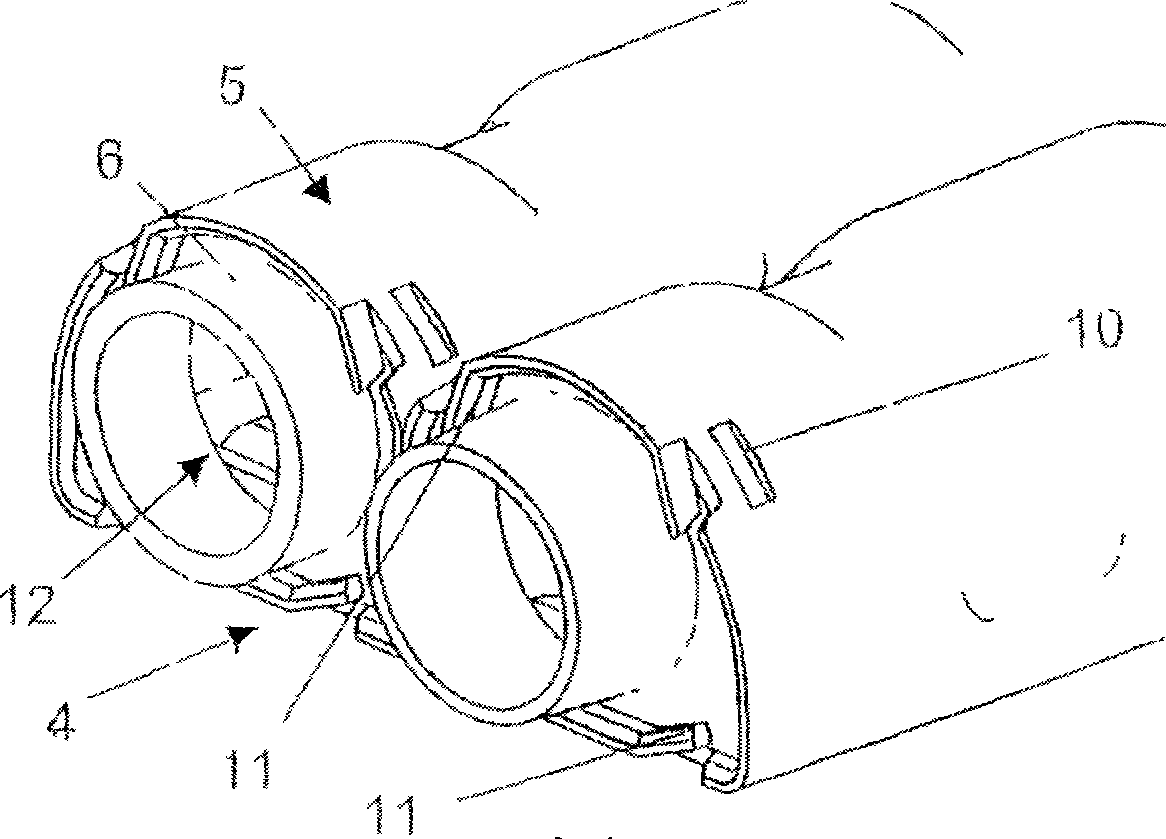

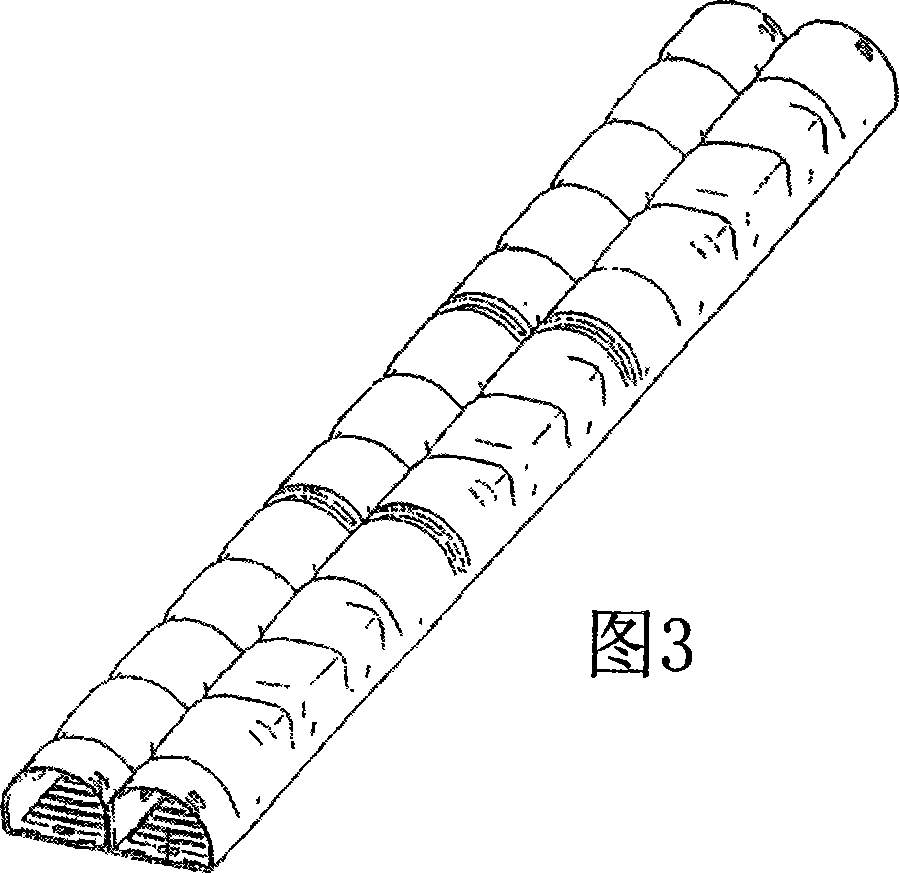

Heat exchanger, in particular a flat pipe evaporator for a motor vehicle air conditioning system

InactiveCN1914473AReduce savingsReduce the risk of sprayingSafety devices for heat exchange apparatusClosure meansPlate heat exchangerAutomobile air conditioning

A collecting tank (2) divides lengthwise into two chambers. Ends of pipes, e.g. flat pipes, are inserted into the base of the collecting tank, which has a tunnel-shaped collecting tank part, i.e. a level collecting tank part to form the base, and covers at each front side. - An INDEPENDENT CLAIM is also included for a motor vehicle's air-conditioning facility with a vaporizer.

Owner:BEHR GMBH & CO KG

Food nutrition freezing method

InactiveCN107751713APreserve nutritional qualityReduce qualityFood freezingFood preservationMuscle tissueNutrition

The invention relates to a food nutrition freezing method. The food nutrition freezing method comprises the following stages at least: (1), a cooling stage, namely cooling food materials at a coolingrate of 2 DEG C / minute or below until a critical freezing temperature point is reached, and entering the next stage; and (2), a first freezing stage, namely rapidly lowering the temperature of the food materials to N DEG C within 30 minutes, wherein N is equal to or higher than 5 DEG C below zero and equal to or lower than 1 DEG C below zero. Compared with the prior art, muscle tissue contractioncaused by coldness is prevented in the cooling stage, and ice crystals are formed inside and outside cells, wherein the formed ice crystals are tiny so that damages to tissues are small; and thus, nutritional quality of the foods is improved.

Owner:JOYOUNG CO LTD

Fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing as well as preparation method thereof

The invention belongs to the technical field of metal processing and particularly relates to fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing as well as a preparation method thereof. The fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing comprises the following components in parts by weight: 5 to 25 parts of carboxylic acid ammonium salt composite antirust agent, 5 to 30 parts of sulfonated castor oil, 2 to 15 parts of water-soluble lubricating agent, 1 to 6 parts of monoacid, 0.5 to 2 parts of mildew-proof fungicide,0.02 to 1 part of defoaming agent and 20 to 55 parts of water. According to the fully-synthesized environmentally-friendly cutting liquid for aluminum alloy processing, which is provided by the invention, through compounding of the sulfonated castor oil and the water-soluble lubricating agent, high lubricating property is provided, and the fully-synthesized environmentally-friendly cutting liquidfor aluminum alloy processing serves as a cutting liquid product not containing oil and can replace semi-synthesized cutting liquid with low oil content under the same condition; in addition, throughcompounding of castor oil acid, organic acid and special alcohol amine, the protective effect that aluminum alloy is not liable to change color is achieved, and high lubricating requirement in the processing process of the aluminum alloy is met.

Owner:GUANGZHOU LANDNOK CHEM TECH

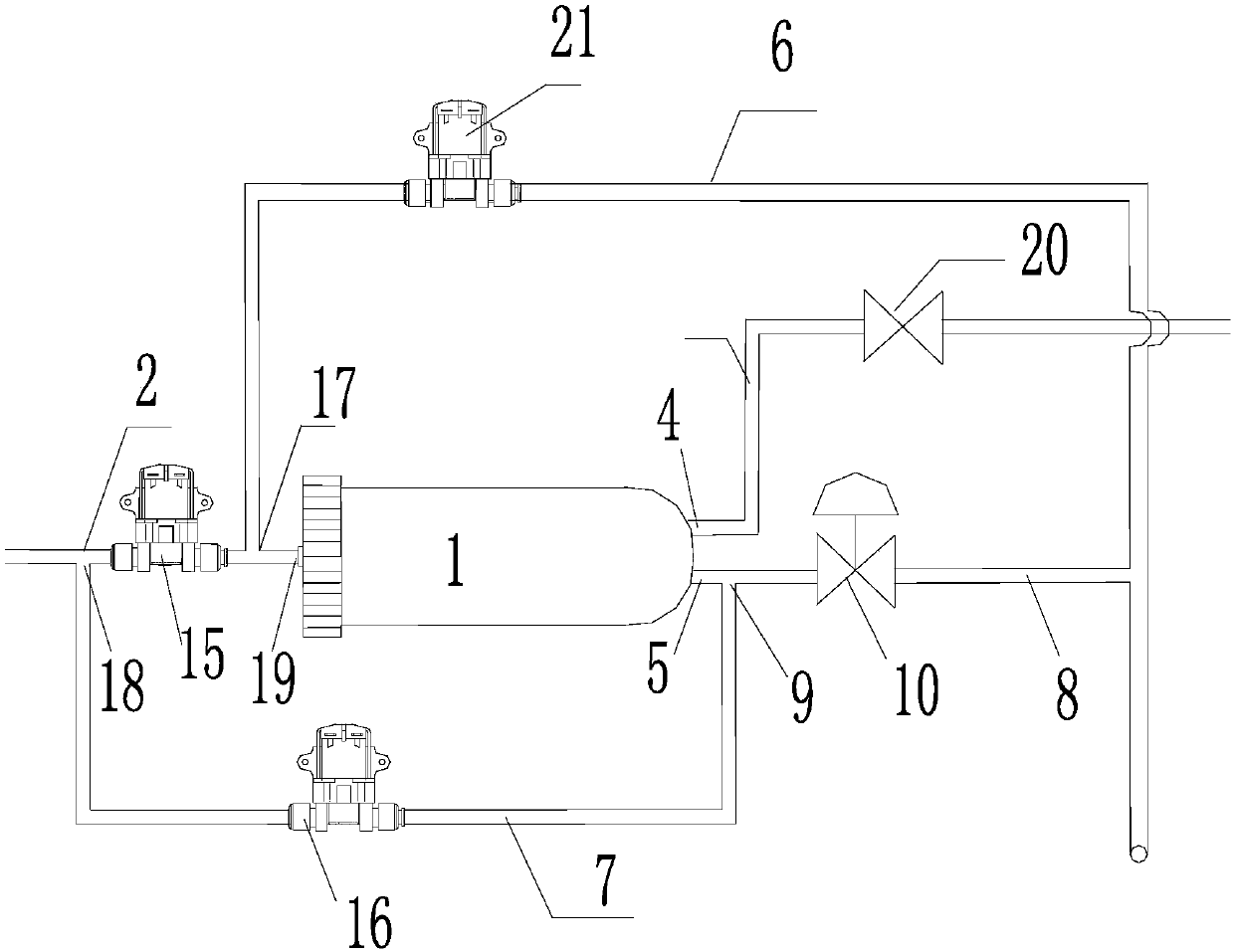

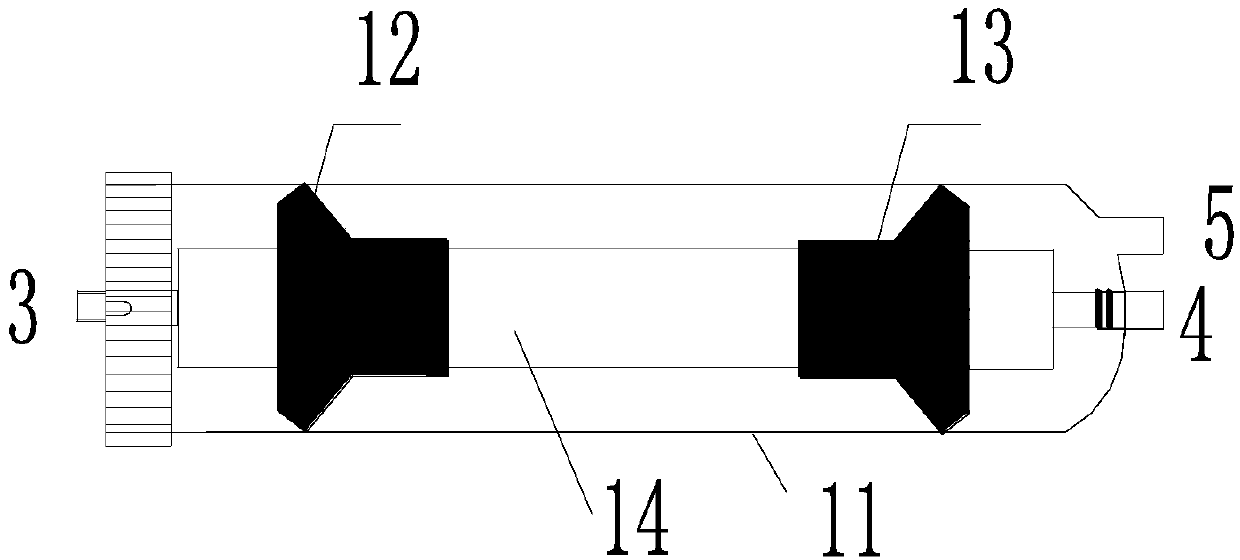

Reverse osmosis membrane filter element flushing system, reverse osmosis system and water purifier

PendingCN107551815AShort lifeExtended service lifeReverse osmosisWater/sewage treatment bu osmosis/dialysisInorganic saltsReverse osmosis

The invention provides a reverse osmosis membrane filter element flushing system, a reverse osmosis system and a water purifier, wherein the reverse osmosis membrane filter element flushing system comprises a reverse osmosis membrane filter element, the reverse osmosis membrane filter element comprises a water inlet connected with a water feeding pipe, a water purification opening through which pure water flows out, and a concentrated water opening through which concentrated water flows out, flushing water can flow into the reverse osmosis membrane filter element through the concentrated wateropening, and after flushing the concentrated water opening, the flushing water is drained through the water inlet. The reverse osmosis membrane filter element flushing system has a forward flushing function for a reverse osmosis membrane and also has a reverse flushing function; by reverse flushing for the reverse osmosis membrane, the high-pressure flushing water can act on an inorganic salt position such as carbonate to enable the carbonate to be released and discharge the carbonate, so that retention of inorganic salt deposits is reduced, the service life of the reverse osmosis membrane isprolonged, and the reverse osmosis membrane purification capacity is greatly improved.

Owner:GREE ELECTRIC APPLIANCES INC

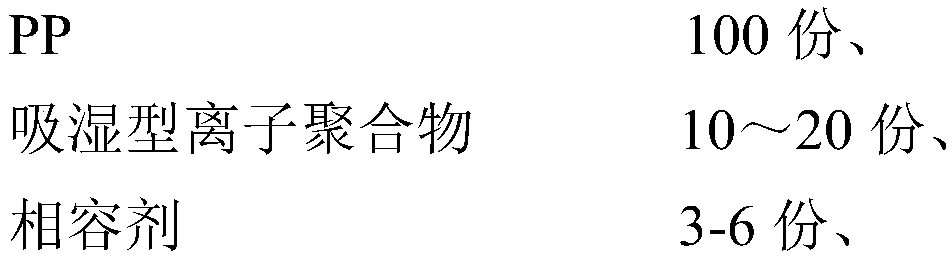

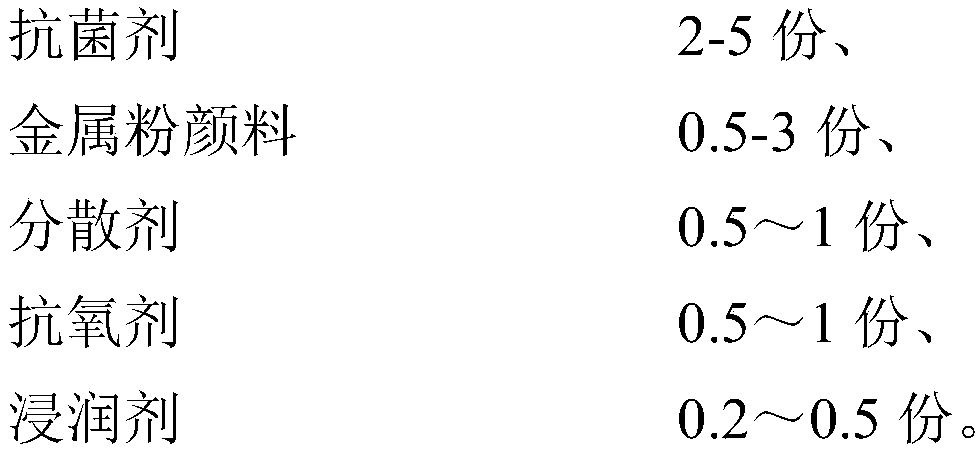

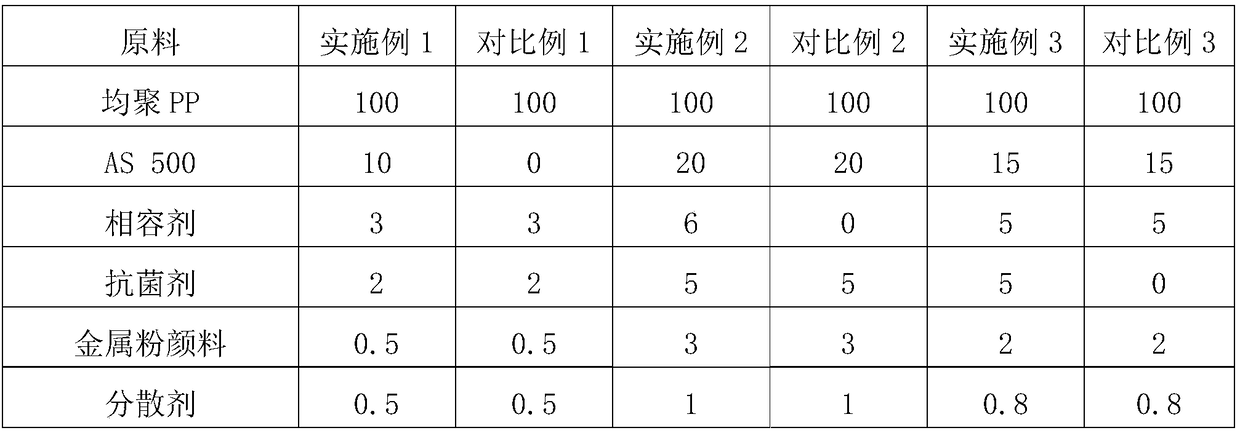

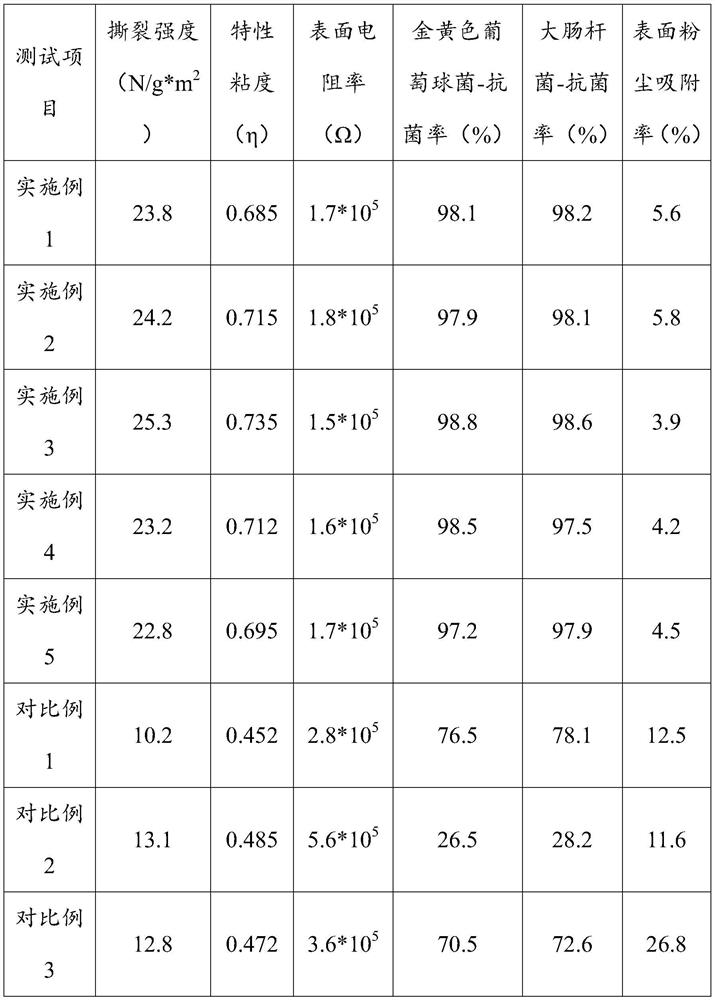

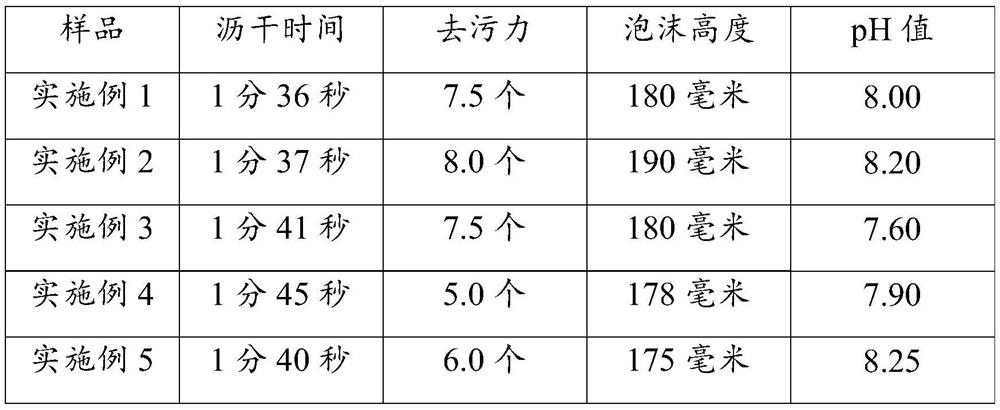

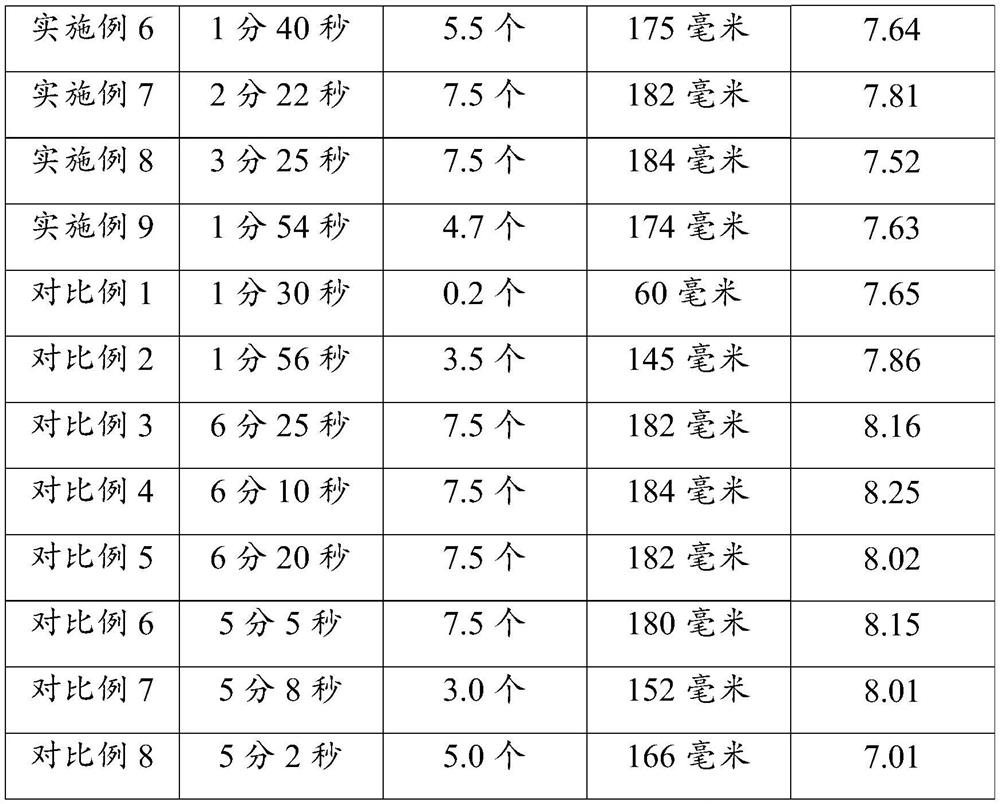

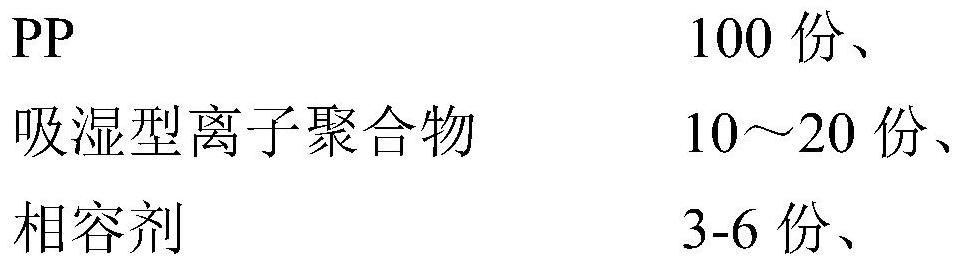

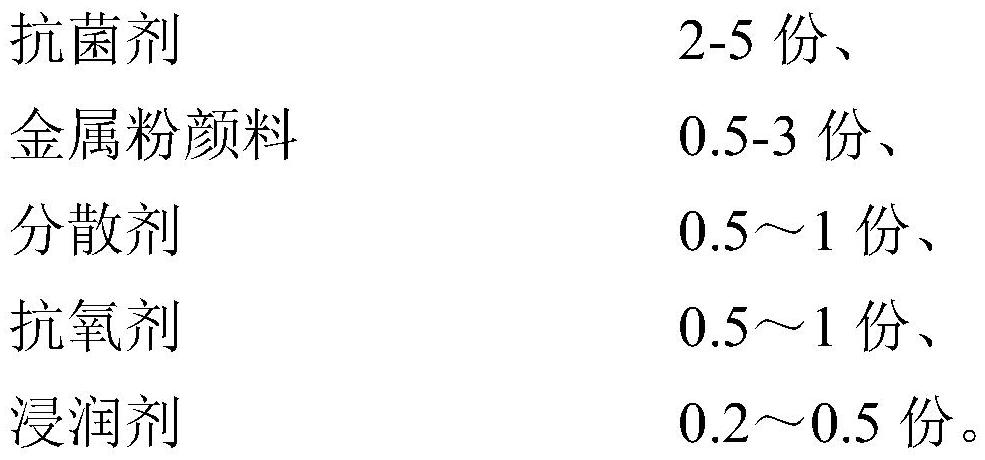

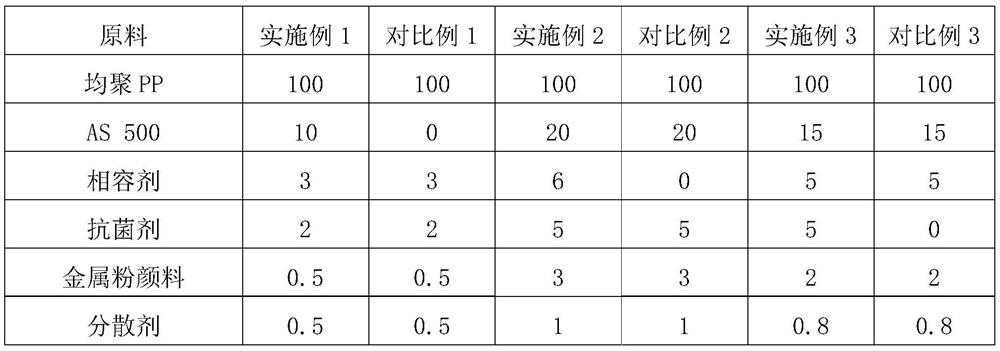

Antibacterial and dust adsorption-free spray-free PP material and preparation method thereof

The invention discloses an antibacterial and dust adsorption-free spray-free PP material and a preparation method thereof. The antibacterial and dust adsorption-free spray-free PP material includes, by weight parts, 100 parts of PP, 10-20 parts of hygroscopic ionic polymer, 3-6 parts of compatibilizer, 2-5 parts of antibacterial agent, 0.5-3 parts of metal powder pigment, 0.5-1 part of dispersingagent, 0.5-1 part of antioxidant and 0.2-0.5 part of infiltrant. The prepared material has the advantages of excellent metal spray-free effect and good dust adsorption resistance and antibacterial property, the problem of flow marks of a conventional metal spray-free effect material can be effectively solved, and the antibacterial and dust adsorption-free spray-free PP material is suitable for occasions where bacteria are bred easily and dust adsorption is high, and the antibacterial and dust adsorption-free spray-free PP material has a wide range of uses in the fields of automobiles, home appliances, and household goods.

Owner:上海日之升科技有限公司

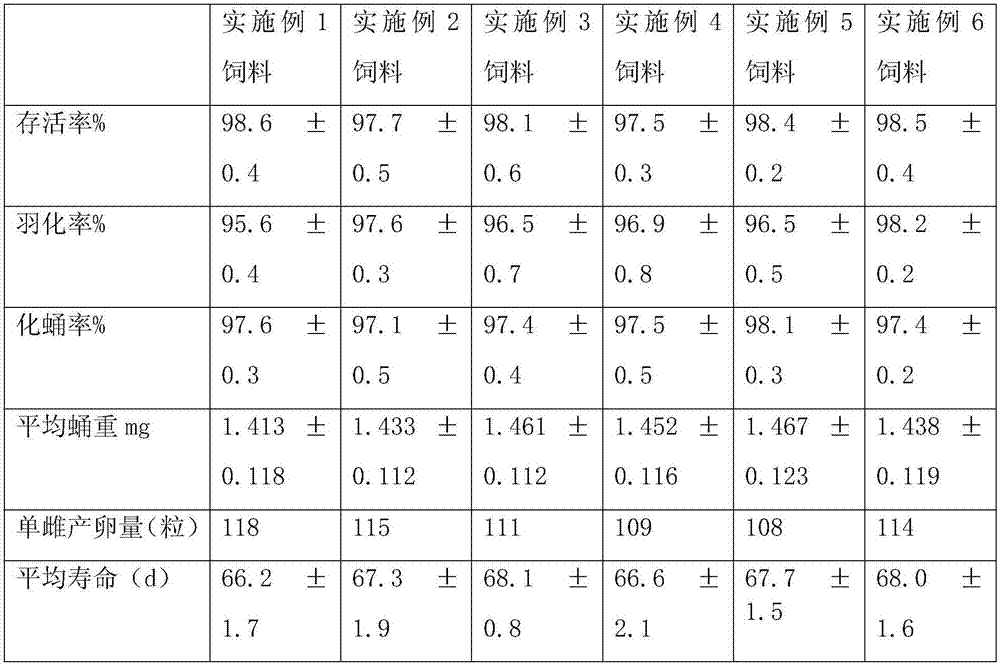

High-nutrition artificial feed for drosophila melanogaster and preparation method of artificial feed

InactiveCN106974140AGood regulationPromote rapid growthFood processingAnimal feeding stuffSemenWheat Brans

The invention provides high-nutrition artificial feed for drosophila melanogaster. The artificial feed is prepared from components of raw materials in parts by weight as follows: 50-80 parts of banana paste, 40-60 parts of mango paste, 40-60 parts of yellow peach paste, 10-20 parts of wheat bran powder, 20-30 parts of royal jelly, 10-20 parts of soybean meal, 1-2 parts of chitosan, 2-4 parts of a semen coicis extract, 10-20 parts of yeast powder, 5-10 parts of agar, 0.5-1.5 parts of a preservative and 100-200 parts of water. The novel high-nutrition feed prepared with the preparation method according to the proportion is used for feeding test drosophila melanogaster all the year round, meanwhile, the survival rate, pupation rate, eclosion rate and single-female egg laying quantity of the test drosophila melanogaste fed with the synthetic feed are all superior to those of drosophila melanogaster fed with natural feed, and the average pupal weight of male and female drosophila melanogaster is larger than that of drosophila melanogaster fed with the natural feed.

Owner:广东人为峰健康管理科技有限公司

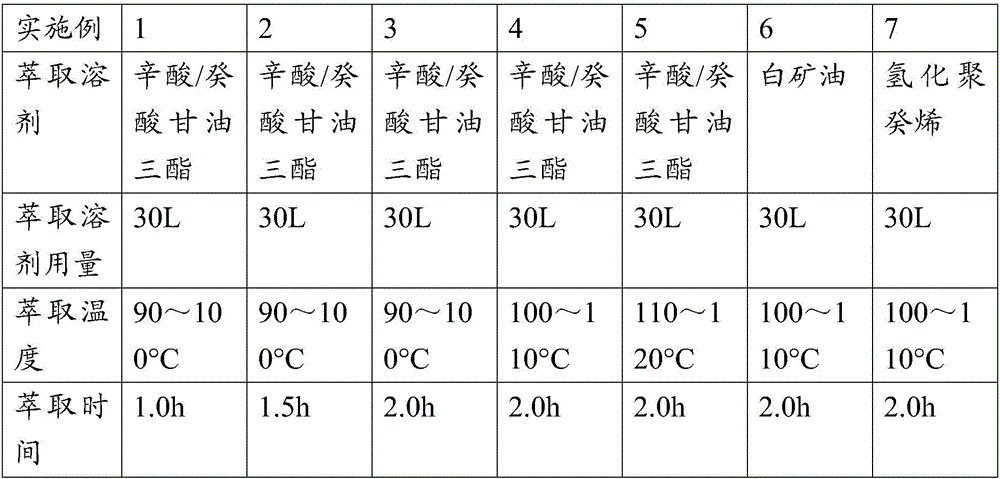

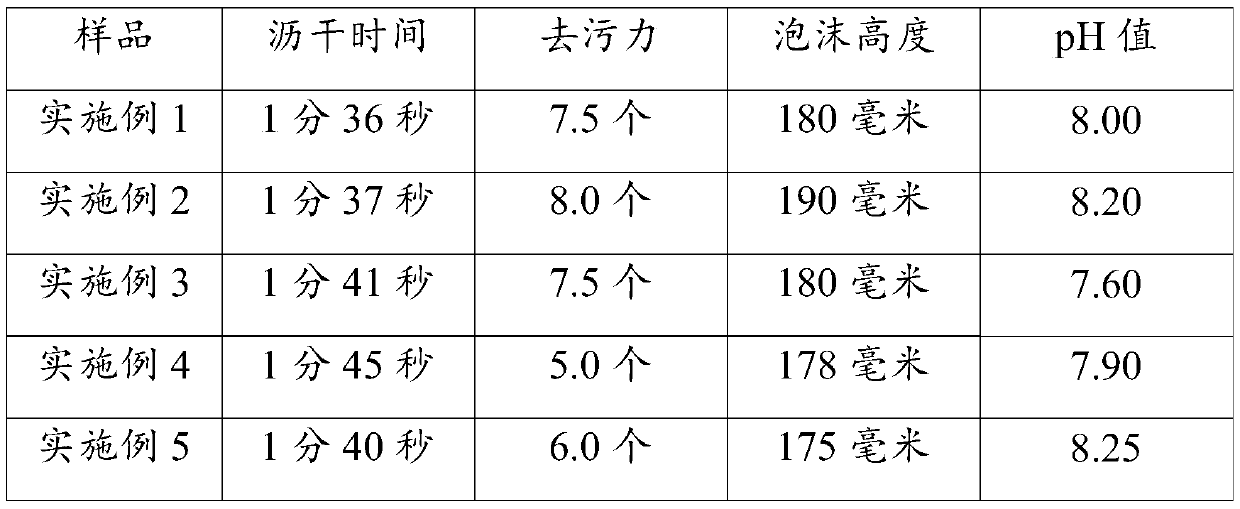

Personal care essence oil containing alkannin and preparation method and application thereof

PendingCN106176465AGood light and heat stabilityLight skin feelCosmetic preparationsOrganic active ingredientsSolventPersonal care

The invention provides personal care essence oil containing alkannin. The personal care essence oil contains alkannin and an extracting solvent, wherein the extracting solvent is synthetized oil. The personal care essence oil has better light and heat stability and is lighter and thinner in skin feeling. The problem that existing lithospermum oil is unstable and easily rancidifies is also solved while the used extracting solvent ensures that the alkannin is effectively extracted. In addition, the sterilization temperature can be properly improved, the risk of microbe breeding can be reduced and the product quality can be comprehensively improved by adopting a preparation process. The invention further provides a preparation method and application of the personal care essence oil containing the alkannin and a cosmetic compound containing the personal care essence oil containing the alkannin.

Owner:YUNNAN BAIYAO GROUP

Liquid detergent and preparation method and applications thereof

ActiveCN110257186AIncreased draining rateShort stayDetergent mixture composition preparationAmpholytes/electroneutral surface-active compoundsCelluloseSodium acetate

The invention provides a liquid detergent and a preparation method and applications thereof, and relates to the technical field of daily chemical products. The liquid detergent comprises following components in percentage by weight: 5 to 40% of an anionic surfactant, 0.5 to 15% of a zwitter ionic surfactant, and 0.05 to 1.0% of a cellulose composition; wherein the cellulose composition comprises cationized hydroxyethyl cellulose, sodium acetate, and isopropanol. Through the cooperation among cationized hydroxyethyl cellulose, the anionic surfactant, and the zwitter ionic surfactant, a hydrophobic film is formed on the surface of washed tableware, the retention time of water on the tableware surface is reduced, the drying time of tableware is obviously reduced after washing; the generated water stains on the tableware surface are reduced; and at the same time, the growth of bacteria on the tableware is inhibited.

Owner:ZHONGSHAN LANJU DAILY CHEM IND CO LTD

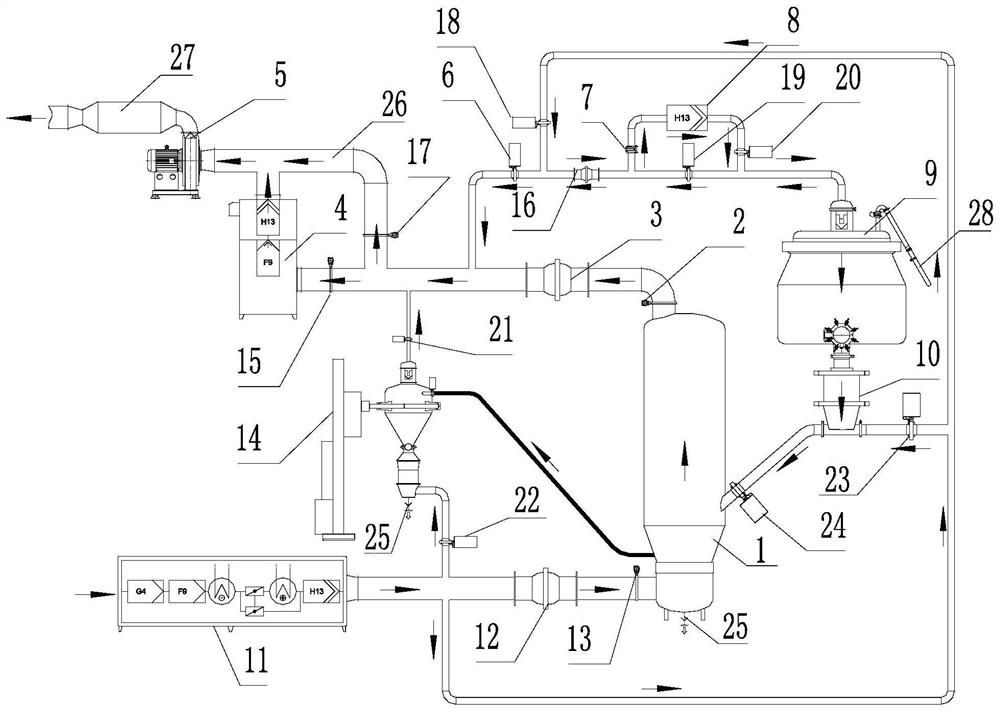

Wet granulation production system and use method

PendingCN112545892AReduce manufacturing costReduce use costDrying solid materials with heatGranular material dryingAir volumeFluidized bed

The invention relates to a wet granulation production system. The wet granulation production system comprises a wet granulator, a wet straightening granulator, a fluidized bed, a lifting straighteninggranulator, an air inlet assembly and an exhaust assembly, wherein the wet granulator, the wet straightening granulator and the lifting straightening granulator are all connected with an air outlet of an air inlet assembly through pipelines, a material suction component is arranged on the wet granulator, and the wet granulator, the fluidized bed and the lifting straightening granulator are all connected with an air inlet of the exhaust assembly through pipelines. A use method of the wet granulation production system comprises the following steps: step S1.1, negative-pressure feeding of the wet granulator; S1.2, negative-pressure feeding of the fluidized bed; and S1.3, negative-pressure feeding of the lifting straightening granulator: drying the materials in the fluidized bed, communicating the lifting straightening granulator with the exhaust assembly and communicating the fluidized bed with the lifting straightening granulator, and adjusting the air inlet volume and the air exhaust volume of the fluidized bed, so that the materials are sucked into the lifting straightening granulator by the fluidized bed in a vacuum manner. The wet granulation production system has the advantagesof being simple and reliable in structure, beneficial to reduction of equipment manufacturing cost and use cost and the like.

Owner:TRUKING TECH LTD

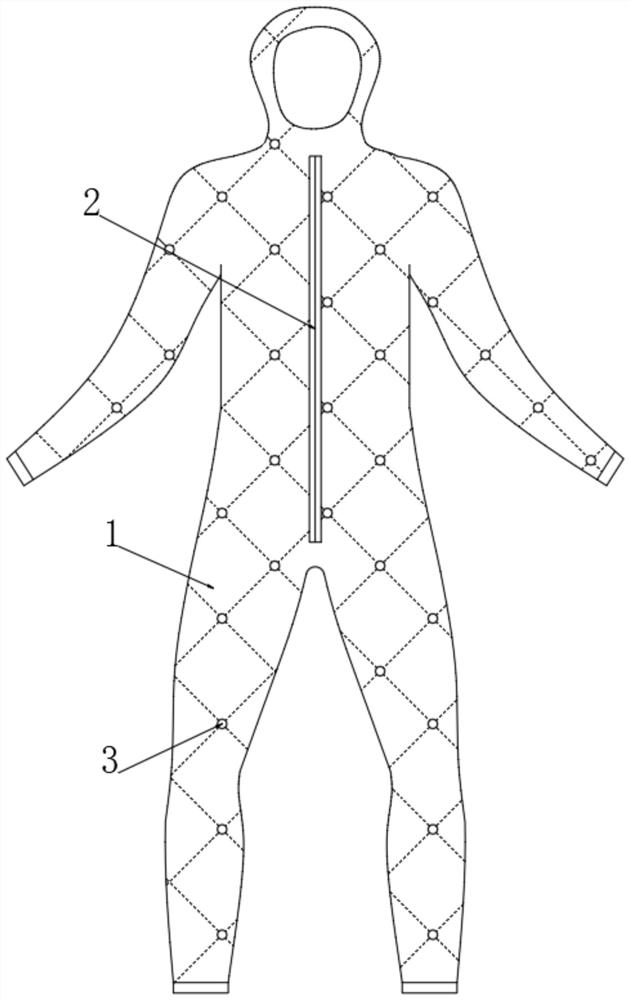

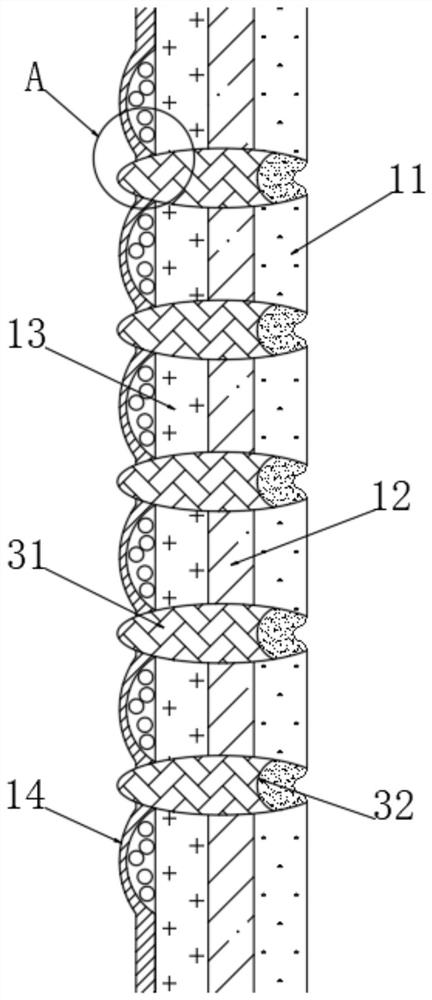

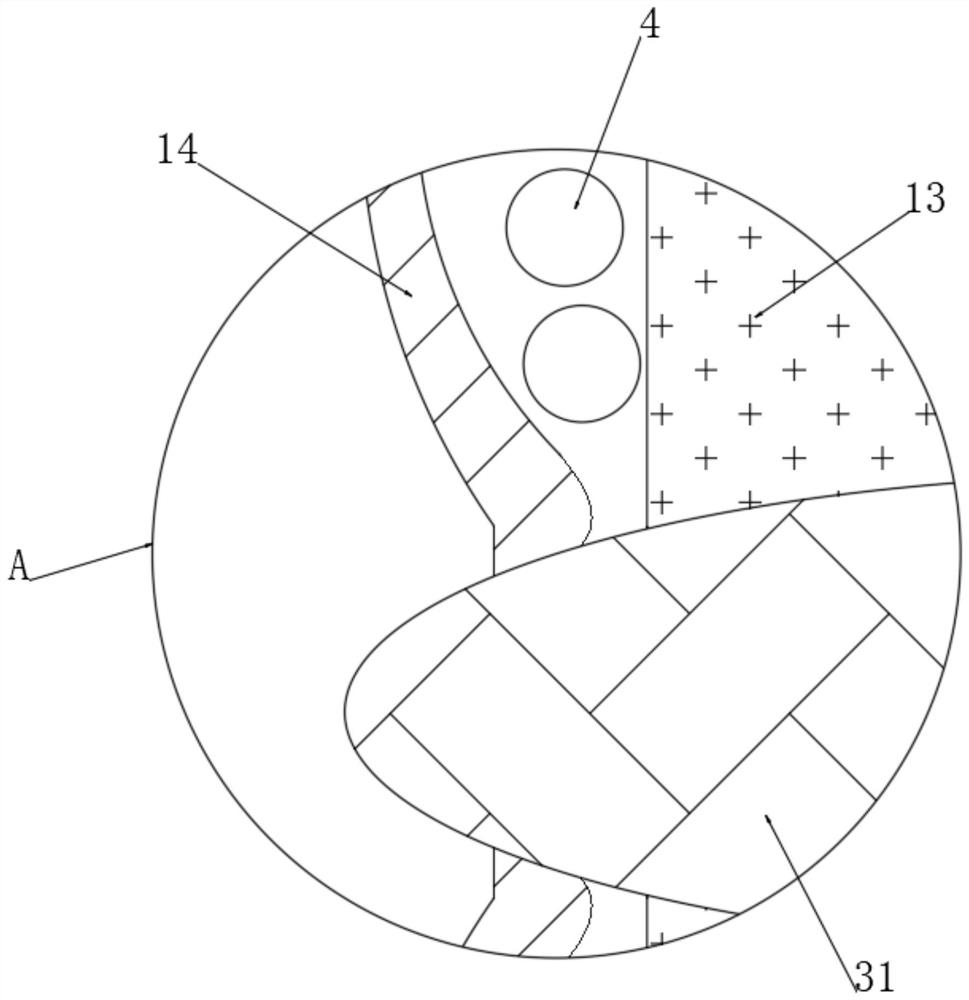

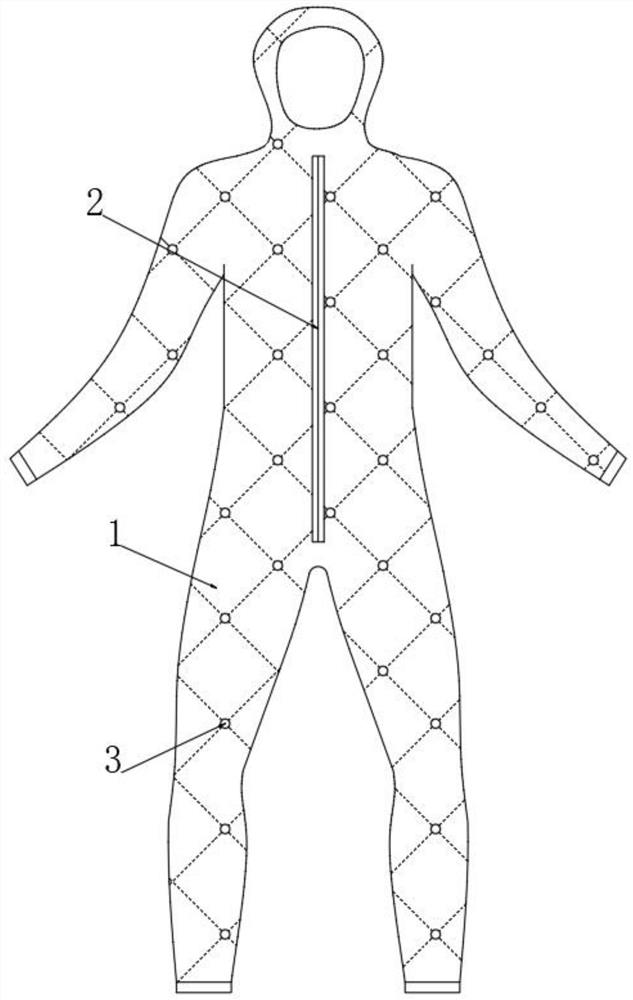

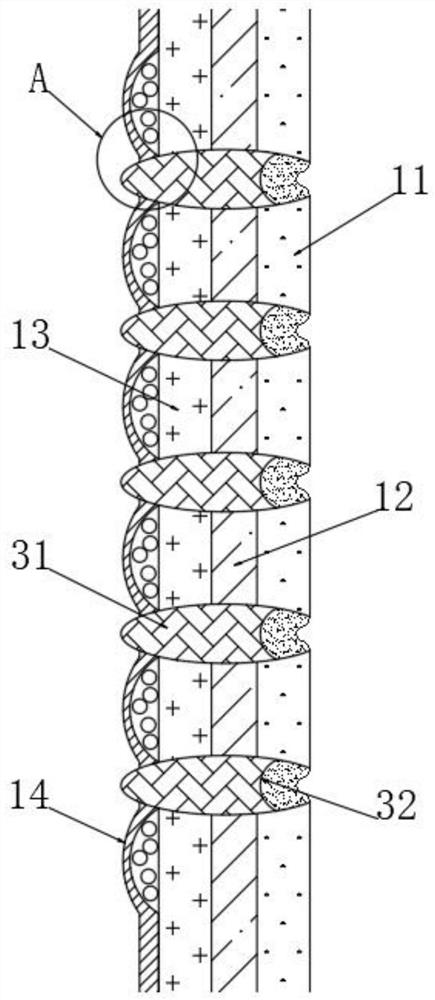

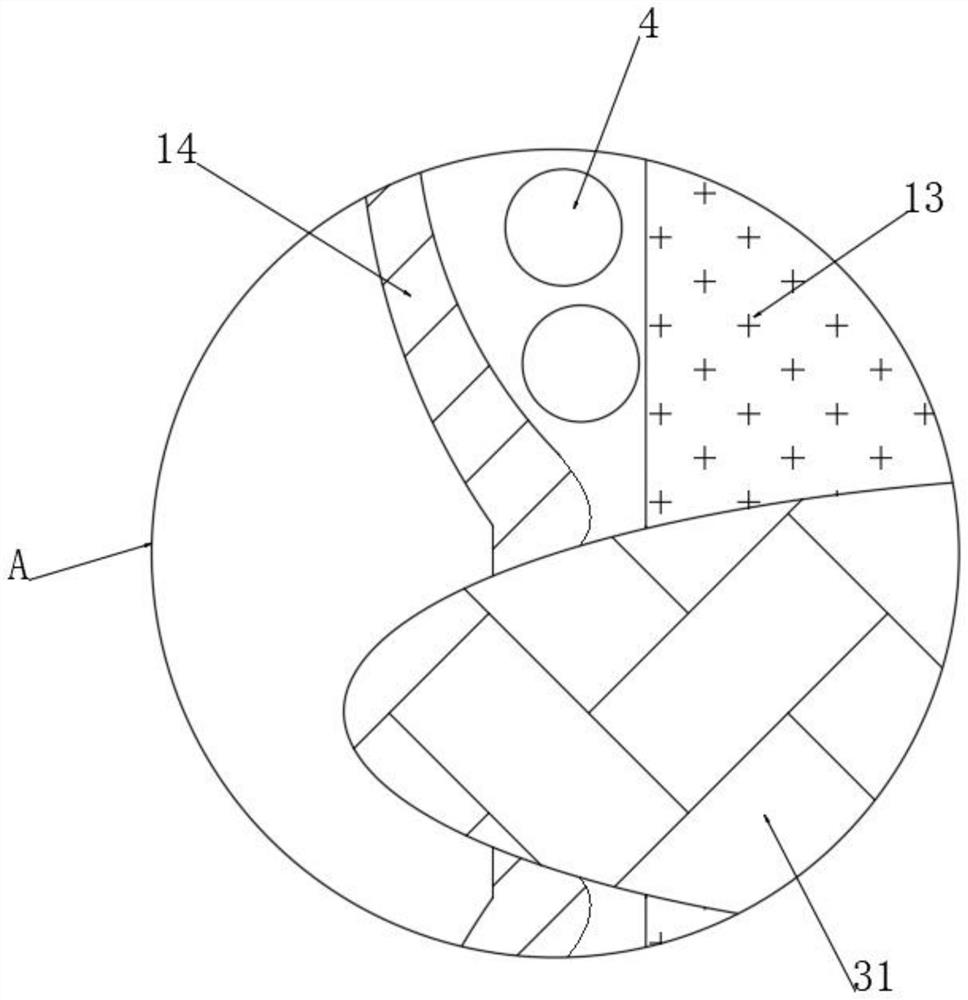

Breathable waterproof multifunctional grid protective clothing

InactiveCN113068879ACapable of reabsorbing waterPromote absorptionProtective garmentSpecial outerwear garmentsEngineeringProtective Garment

The invention discloses breathable waterproof multifunctional grid protective clothing, and belongs to the field of protective clothing. The breathable waterproof multifunctional grid protective clothing can effectively adsorb water vapor generated in the protective clothing through the cooperative effect of inner suction breaking balls and transverse water collecting balls, and after the protective clothing is worn for a long time, and a worker can manually keep away from the transverse water collecting balls to press the protective clothing body, so that on the one hand, water adsorbed in the protective clothing body is squeezed out and then flows out to be adsorbed by the transverse water collecting balls, the inner suction breaking balls are enabled to have the effect of absorbing water again, the absorption capacity of the interior of the protective clothing to water vapor generated by the human body is remarkably improved, the amount of water vapor in contact with the skin is reduced, and the hidden danger of bacterium breeding is reduced while the comfort level is improved; and on the other hand, when the inner suction breaking balls are pressed, the inner breaking balls are broken, the extrusion force on the inner pressure water absorption balls is relieved, the inner pressure water absorption balls are expanded, the water absorption performance is improved, and then the water absorption performance reduced by part of residual water vapor is effectively made up.

Owner:陈斌

Antibacterial dust-adsorption-resistant composite plastic master batch and preparation method thereof

The invention discloses an antibacterial dust adsorption resistant composite plastic master batch, which is prepared from the following raw materials in parts by weight: 45-50 parts of polypropylene, 25-35 parts of a filler, 5-7 parts of a plasticizer, 4-6 parts of a lubricant, 3-5 parts of a polyhydroxy chemical coupling agent, 3.5-4.5 parts of a performance additive, 1-2 parts of a composite antioxidant, 1-3 parts of a composite antibacterial agent, 1-3 parts of a composite antistatic agent, 1-2 parts of a light stabilizer, 1-2 parts of a flexibilizer, 2-4 parts of hydroxymethyl cellulose, 1-3 parts of an impact modifier, 4-6 parts of a porous ceramic preform, 1-3 parts of a nano flame retardant and 4-6 parts of carbon nanofibers. According to the invention, the defects in the prior art are overcome, the design is reasonable, the process flow is simple, the antibacterial and dust-adsorption-resistant effects are good, and the social use value and the application prospect are relatively high.

Owner:合肥市丽红塑胶材料有限公司

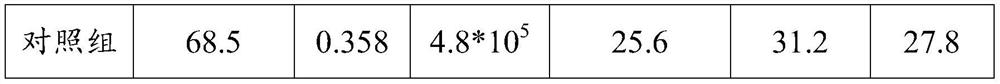

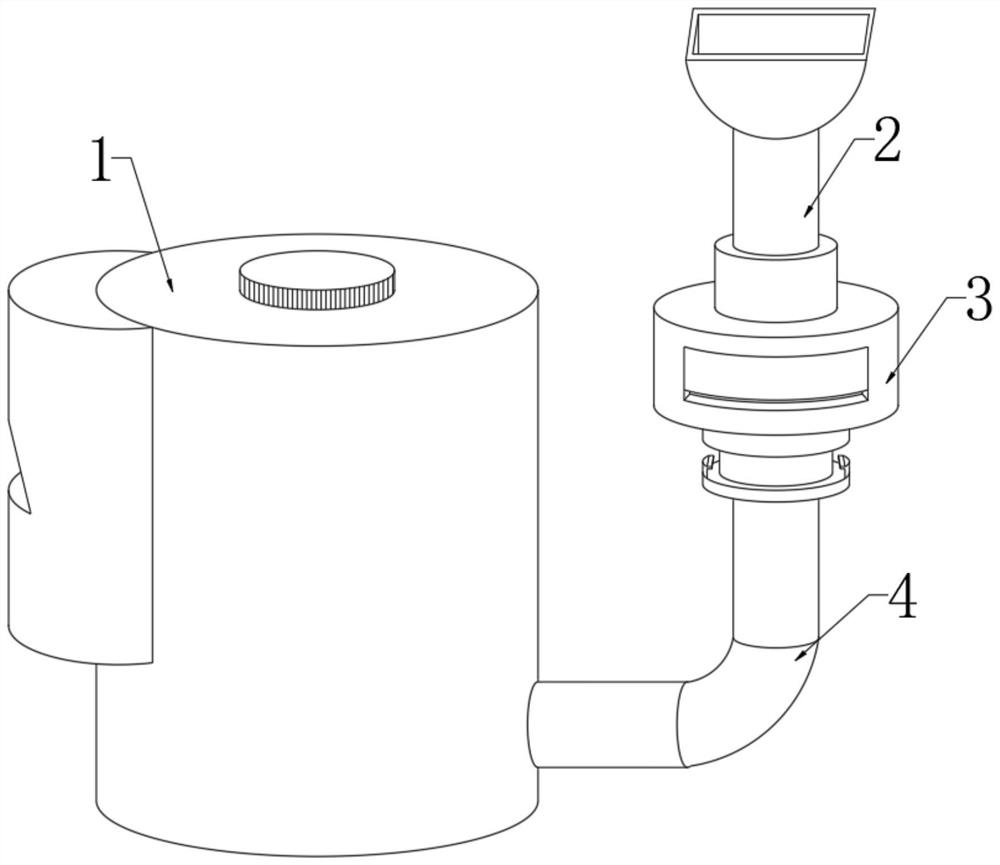

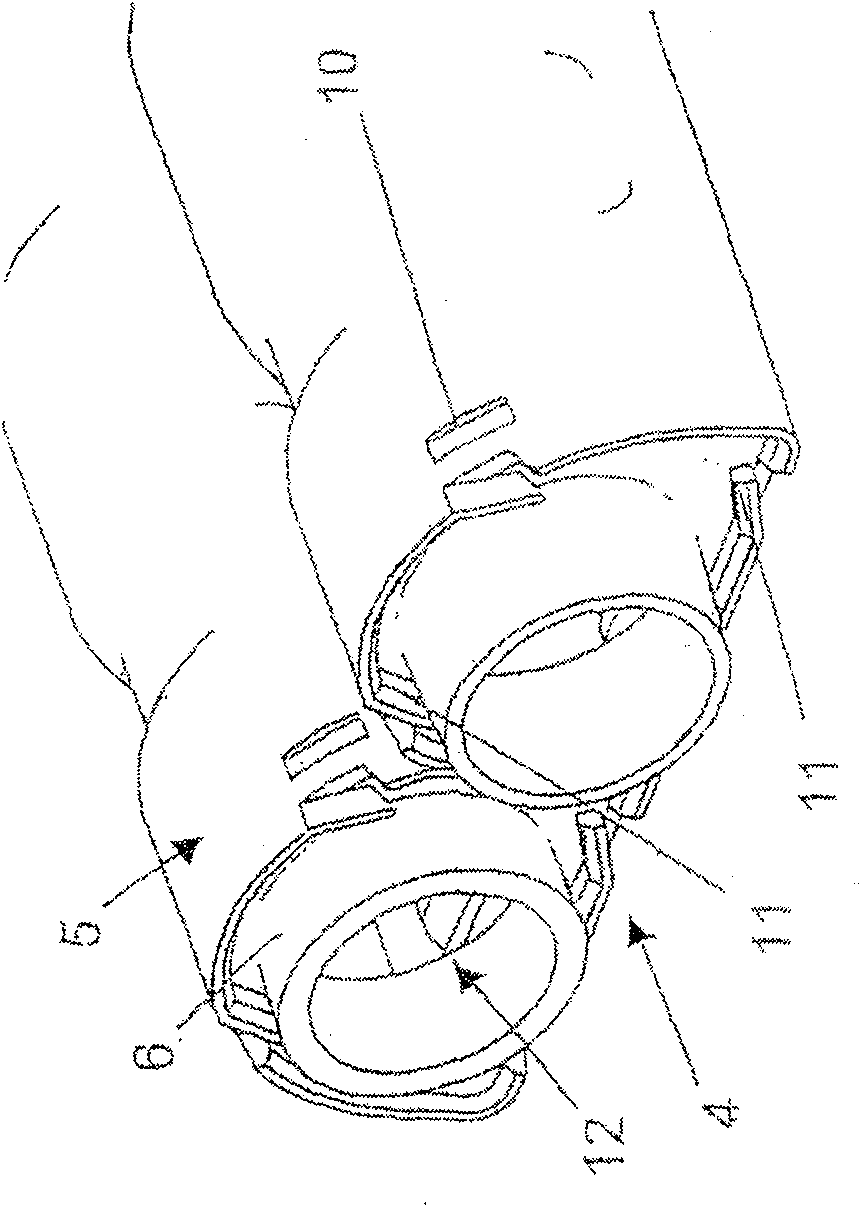

Respiratory training device for lung treatment

InactiveCN113694481AImprove complianceEasy to judge the effect of trainingGymnastic exercisingPhysical medicine and rehabilitationEngineering

The invention provides a respiratory training device for lung treatment, which comprises a respiratory training mechanism, an air blowing pipe, a respiratory filtering mechanism and a connecting air pipe, the connecting air pipe is connected to a connecting hole of the respiratory training mechanism, and the other end of the connecting air pipe is connected to the lower end of the respiratory filtering mechanism; the lower end of the air blowing pipe is connected to the upper end of the respiratory filtering mechanism; compared with the prior art, the device has the following advantages that sound can be made during training, so that the training effect is conveniently judged, the training intensity can be adjusted according to needs, the lung compliance is improved, postoperative complications are reduced and prevented, the interior of a training mechanism can be kept clean, a filter cotton core in a fixed seat is conveniently replaced, the danger of bacterium breeding is reduced, and the safety is improved.

Owner:康文泰

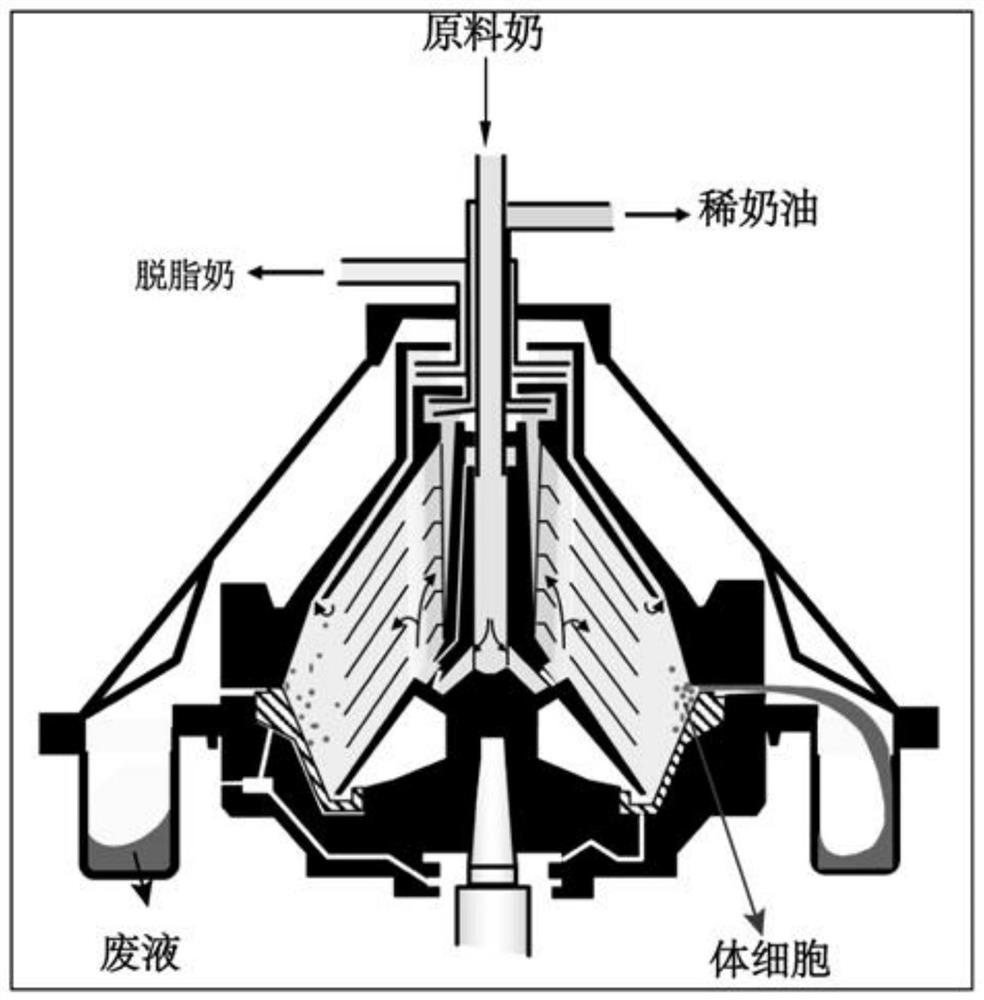

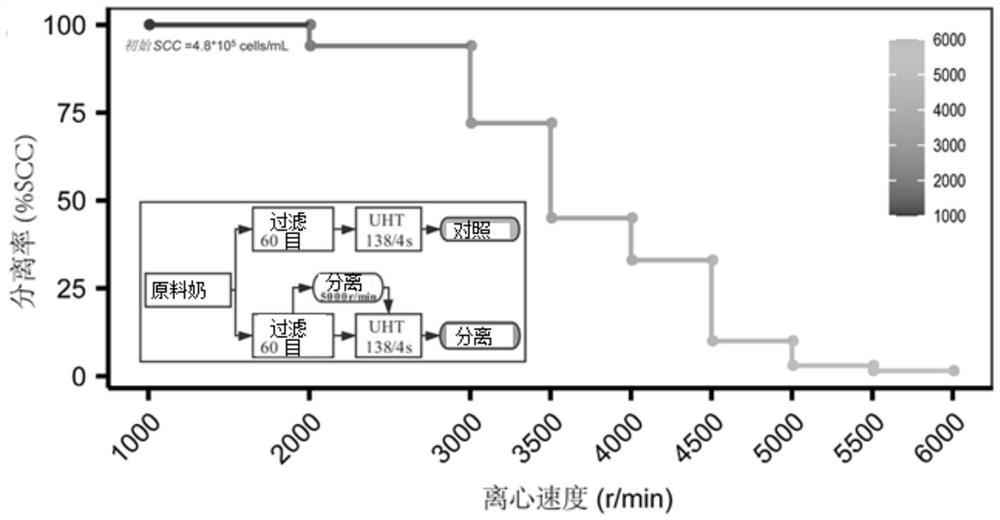

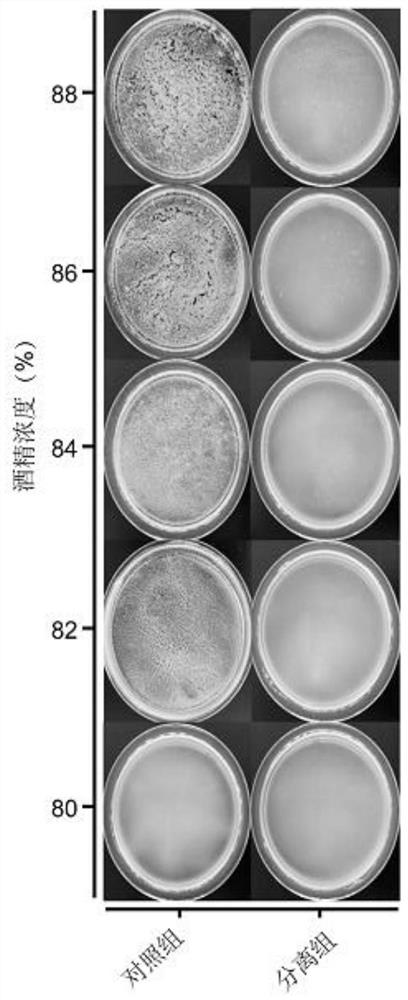

Ultrahigh-temperature sterilized milk, cow milk processing method for improving stability of ultrahigh-temperature sterilized milk and application of ultrahigh-temperature sterilized milk

PendingCN114521587ASimplify the production processProcessing speedMilk preservationOther dairy technologyChemistryRaw milk

The invention provides ultrahigh-temperature sterilized milk, a milk processing method capable of improving the stability of the ultrahigh-temperature sterilized milk and application of the ultrahigh-temperature sterilized milk. The cow milk processing method at least sequentially comprises the following steps: carrying out sterilization and separation treatment on raw milk, backfilling single cream generated by the sterilization and separation treatment into feed liquid, and carrying out ultra-high temperature sterilization treatment. The milk processing method can effectively remove mammary gland infected somatic cells, so that the stability of the ultrahigh-temperature sterilized milk is improved.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Detergent and its preparation method and application

ActiveCN110257186BIncreased draining rateShort stayDetergent mixture composition preparationAmpholytes/electroneutral surface-active compoundsCelluloseSodium acetate

The invention provides a detergent, its preparation method and application, and relates to the technical field of daily chemical products. The detergent of the present invention comprises the following components by weight percentage: 5-40% of anionic surfactant, 0.5-15% of zwitterionic surfactant and 0.05-1.0% of cellulose composition; wherein, the cellulose The composition includes cationized hydroxyethyl cellulose, sodium acetate and isopropanol. The present invention forms a layer of hydrophobic film on the surface of washed tableware through the synergistic cooperation of cationized hydroxyethyl cellulose, anionic surfactant and zwitterionic surfactant, reduces the residence time of water on the surface of tableware, and significantly improves Improve the draining rate of the tableware after washing, reduce water marks and spots on the surface of the tableware, and reduce the risk of bacteria breeding on the tableware.

Owner:ZHONGSHAN LANJU DAILY CHEM IND CO LTD

Antibacterial, dust-resistant, adsorption-free, spray-free PP material and preparation method thereof

ActiveCN109096608BImprove antistatic performanceImprove scratch resistanceIonic polymerizationHome appliance

The invention discloses an antibacterial, dust-resistant, adsorption-free PP material and a preparation method thereof. The antibacterial, dust-resistant, adsorption-free, spray-free PP material consists of the following parts by weight: 100 parts of PP, 10-20 parts of hygroscopic ionic polymer, 3-6 parts of compatibilizer, 2-5 parts of antibacterial agent, 0.5 parts of metal powder pigment ‑3 parts, 0.5‑1 part of dispersant, 0.5‑1 part of antioxidant, 0.2‑0.5 part of wetting agent. The material prepared by the invention has excellent spray-free metal effect, good dust absorption and antibacterial properties, can effectively alleviate the flow mark problem of traditional spray-free metal effect materials, and is suitable for easy-to-breed bacteria and high dust adsorption It has a wide range of uses in the fields of automobiles, home appliances, and household goods.

Owner:上海日之升科技有限公司

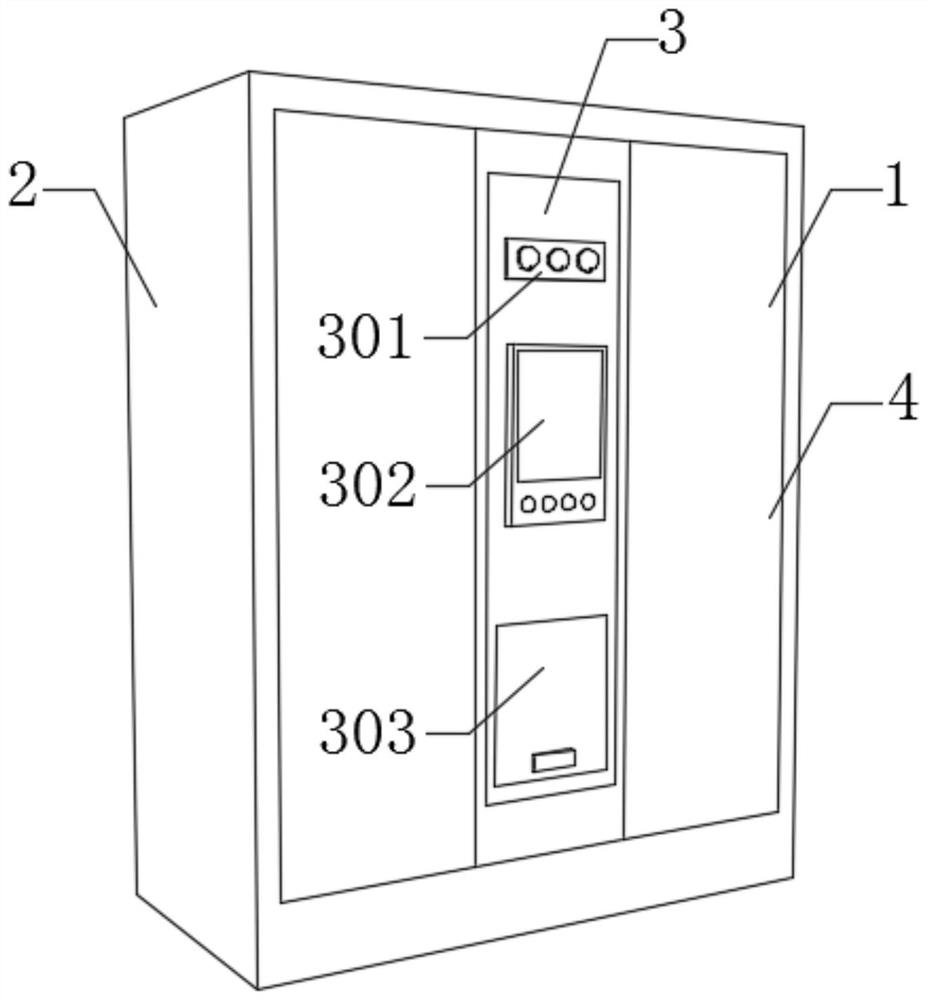

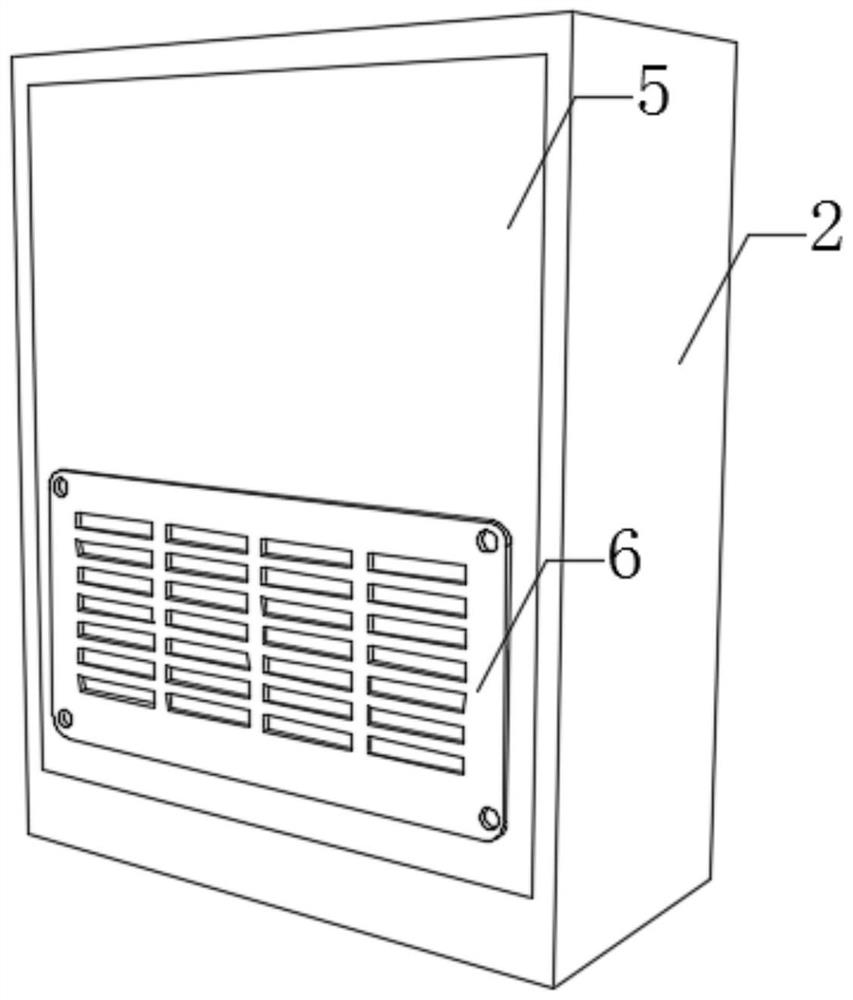

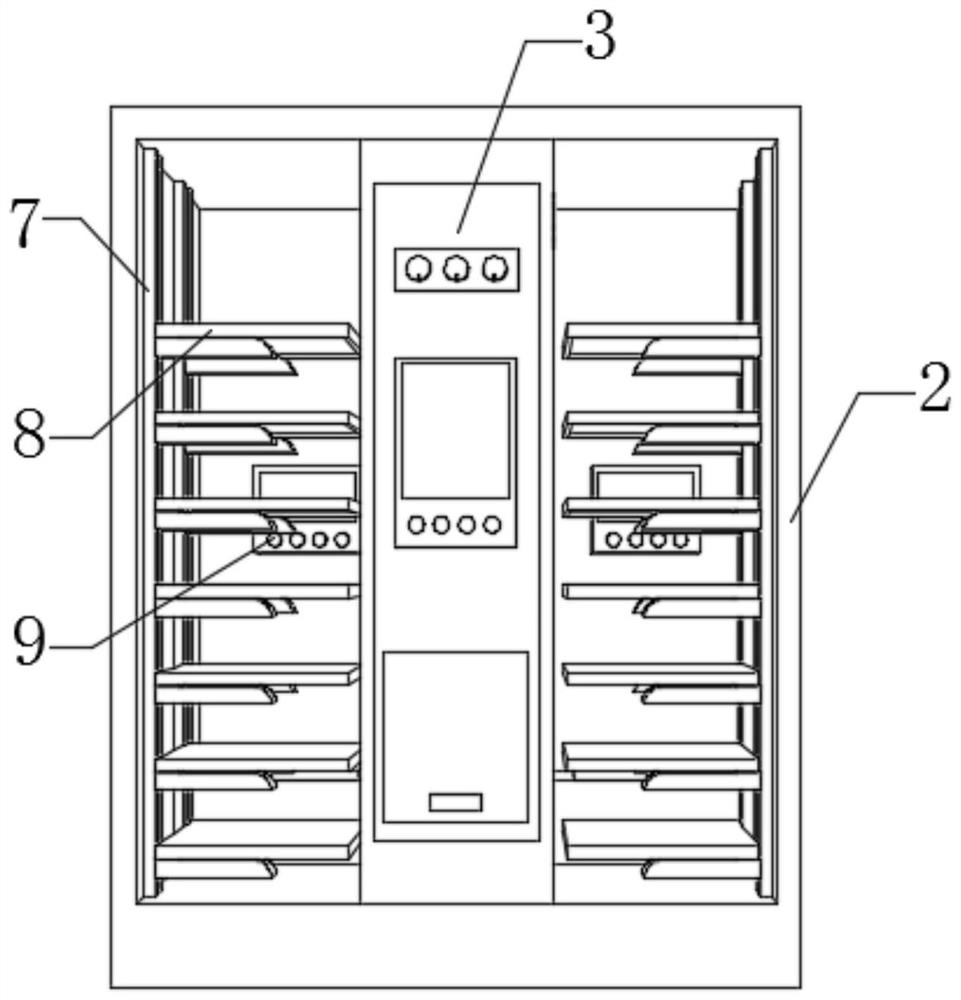

Intelligent sterile article storage cabinet

PendingCN113830403AAvoid expirationQuality improvementCasings with display/control unitsLighting elementsEngineeringLED lamp

The invention discloses an intelligent sterile article storage cabinet. The intelligent sterile article storage cabinet comprises a device body, the device body comprises a box body, an operation panel, cover plates and a back plate, the operation panel is fixedly installed in the middle of one side of the box body, the two sides of the operation panel are movably connected with the sides of the cover plates, one side of each of the cover plates on the two sides is connected with one side of the box body through a hinge, the operation panel comprises three LED indicating lamps, a control panel, a fetching cover plate, an ozone generator, an ultraviolet disinfection lamp, a side plate, a through hole and a sensor, one side surface of the operation panel is electrically connected with the LED indicating lamps, the LED indicating lamps protrude out of the surface of the operation panel, and the three LED lamps are sequentially green, yellow and red from left to right. The condition that sterile articles are out of date due to human factors is effectively avoided, the management quality and level of the sterile articles are effectively improved, the working efficiency of management personnel is improved, and the loss of personnel and the sterile articles is reduced.

Owner:THE WEST CHINA SECOND UNIV HOSPITAL OF SICHUAN

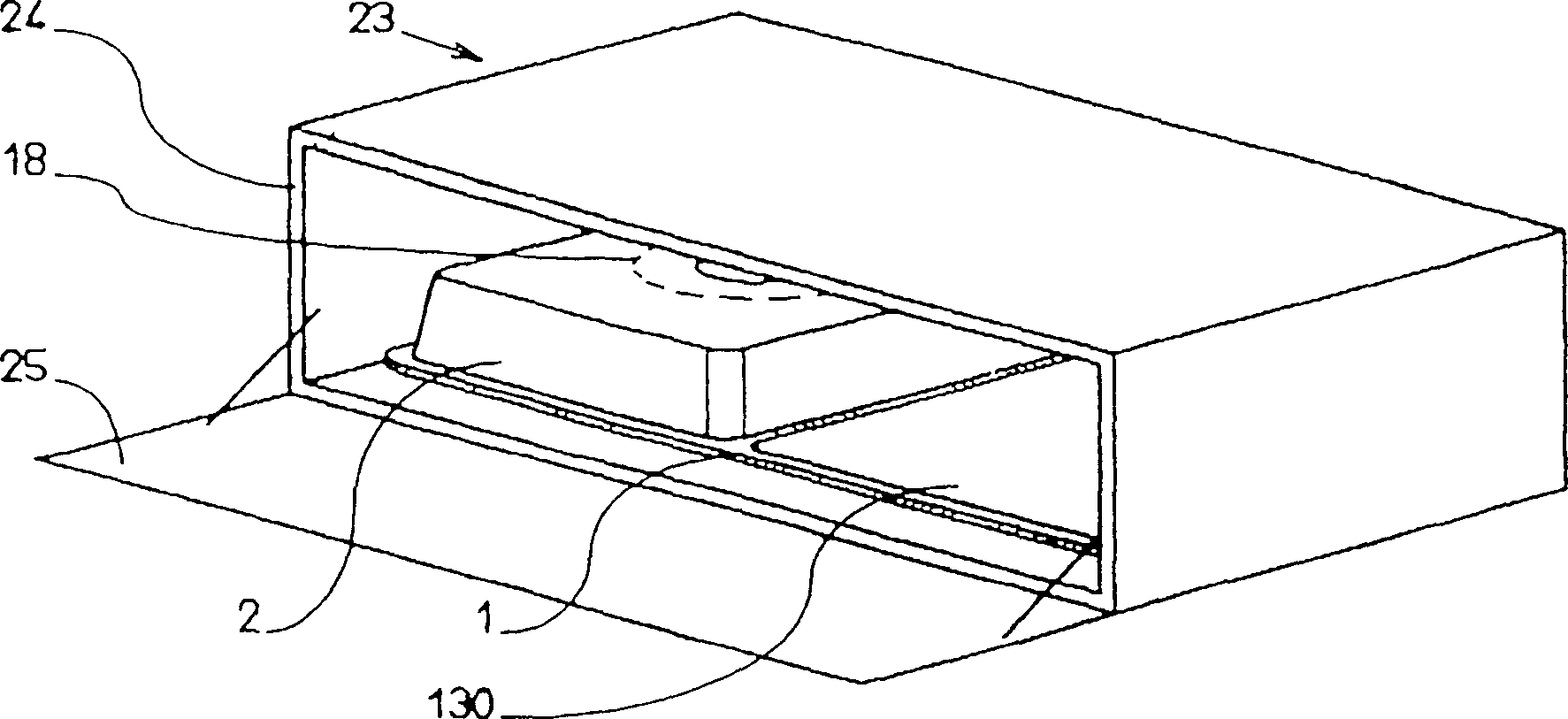

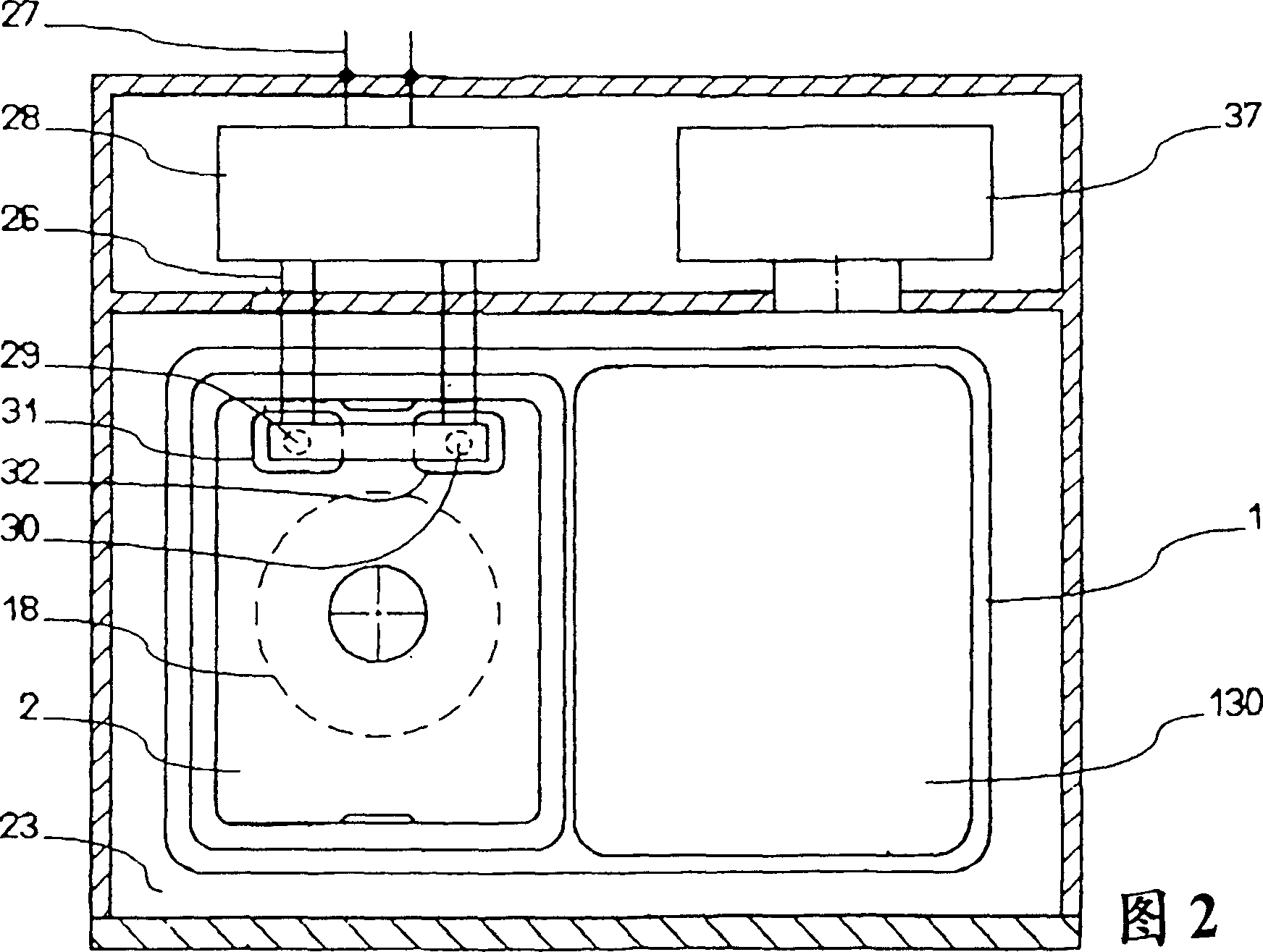

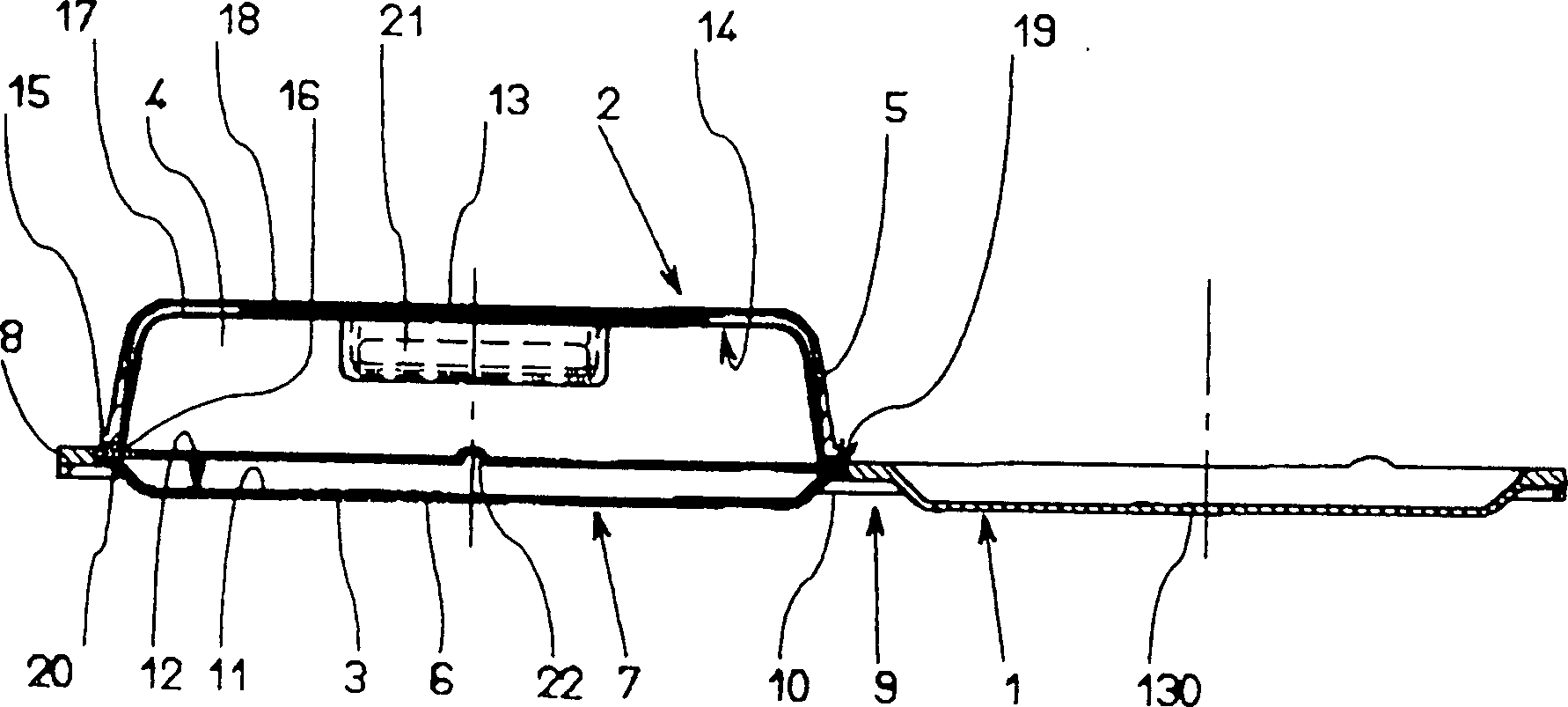

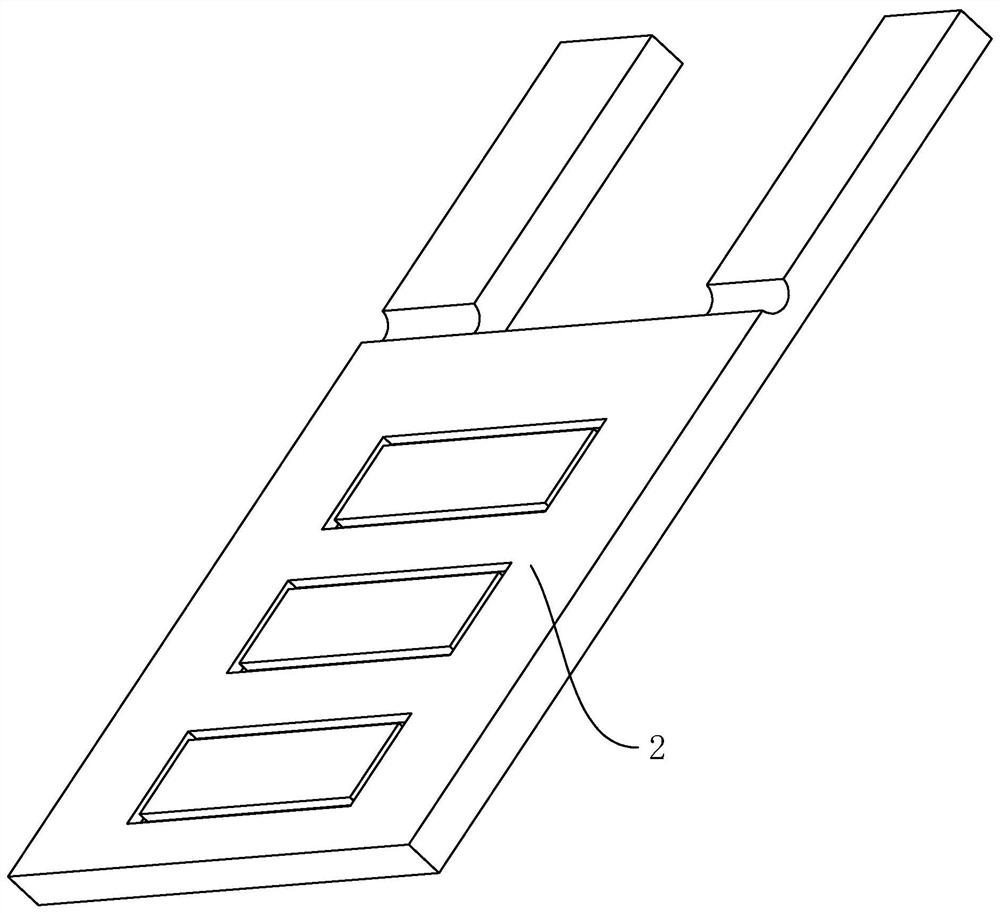

Method and device for instituional distribution of meals

InactiveCN1139355CSimple structureSmall volumeDomestic refrigeratorsFoldable tablesElectricityEngineering

The trolley, for use in a collective catering establishment, has a refrigerated cabinet with an access door (25) for containing a number of ready prepared meals on trays (1). It has a cold generator (37) for keeping the cabinet cool, and a heat source on the inside of a cover (2) on the tray for heating a portion of the meal which is to be eaten hot, fed by an energy transmitting unit. The covered part of the tray is heated in a separate chamber on top of the trolley which takes only one or two trays at the time, and the cover incorporates heat diffusion layers with a coating of black PTFE or enamel.

Owner:民用制品合作公司

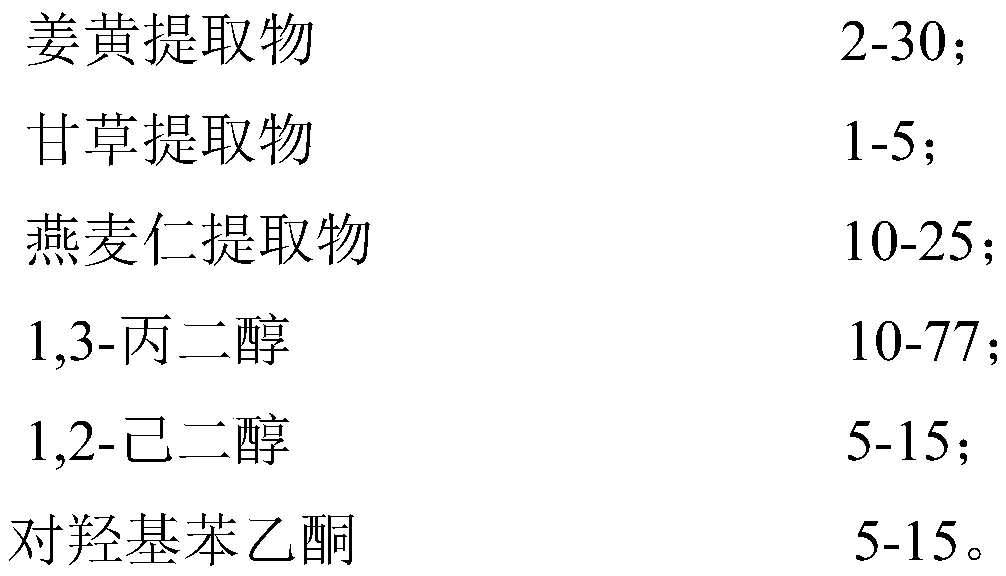

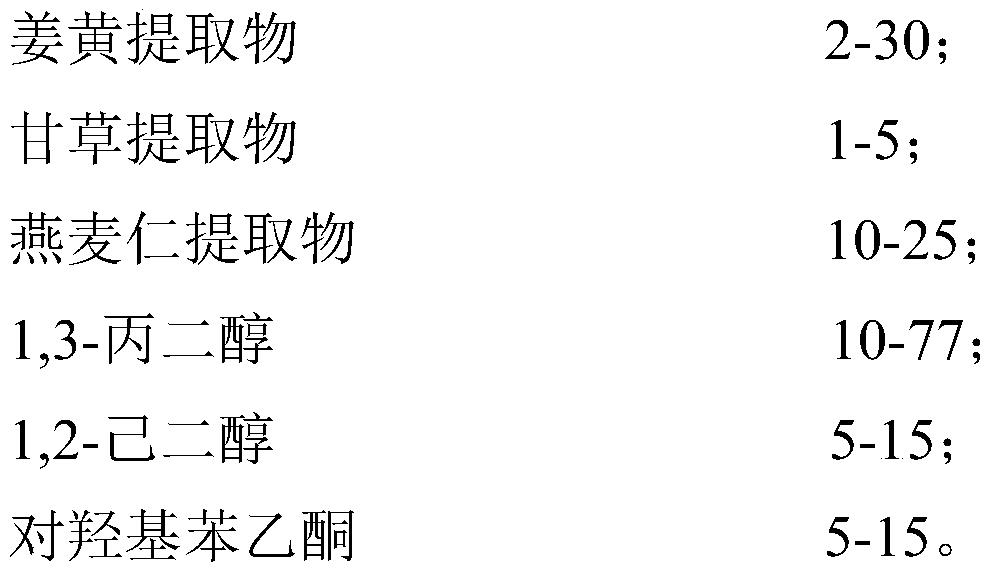

Anti-allergy red-fading composition, preparation method of composition and skin care product

InactiveCN110101642AHypoallergenicSensitiveCosmetic preparationsToilet preparationsMedicineAnti allergy

The invention provides an anti-allergy red-fading composition. The composition is prepared from a rhizoma curcumae longae extract, a radix liquiritiae extract, an oat kernel extract, 1,3-propylene glycol, 1,2-hexanediol and p-hydroxyacetophenone. The invention further provides a preparation method of the anti-allergy red-fading composition and a skin care product containing the anti-allergy red-fading composition. According to the anti-allergy red-fading composition, the preparation method of the composition and the skin care product prepared from the composition, the natural and safe low-sensitivity raw materials for anti-allergy red-fading treatment are selected for use, the sensitization risk of the skin can be effectively reduced, the good stability, antihistamine capacity and anti-irritant capacity can also be achieved, and the anti-allergy red-fading effect is excellent.

Owner:广州市澳源科技集团有限公司

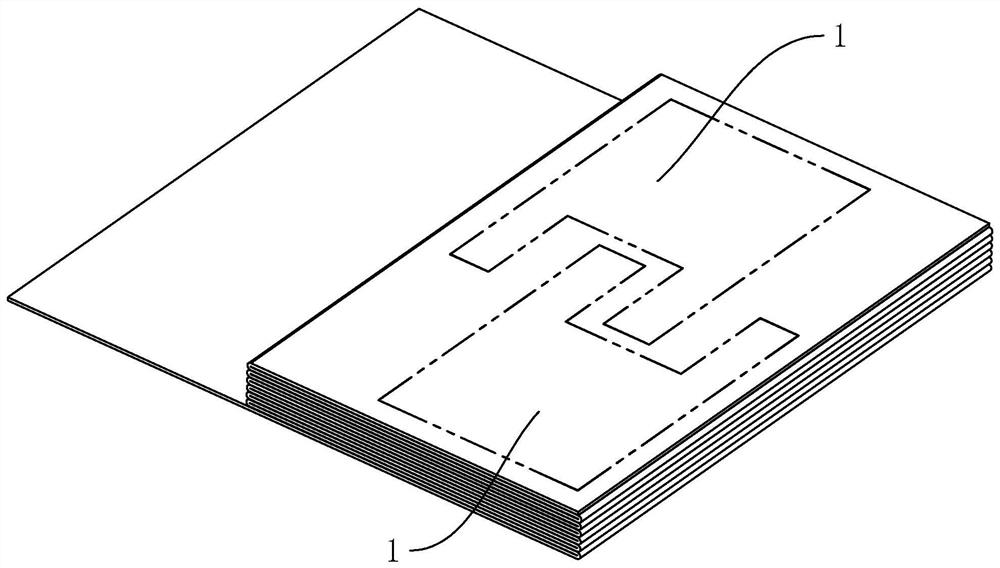

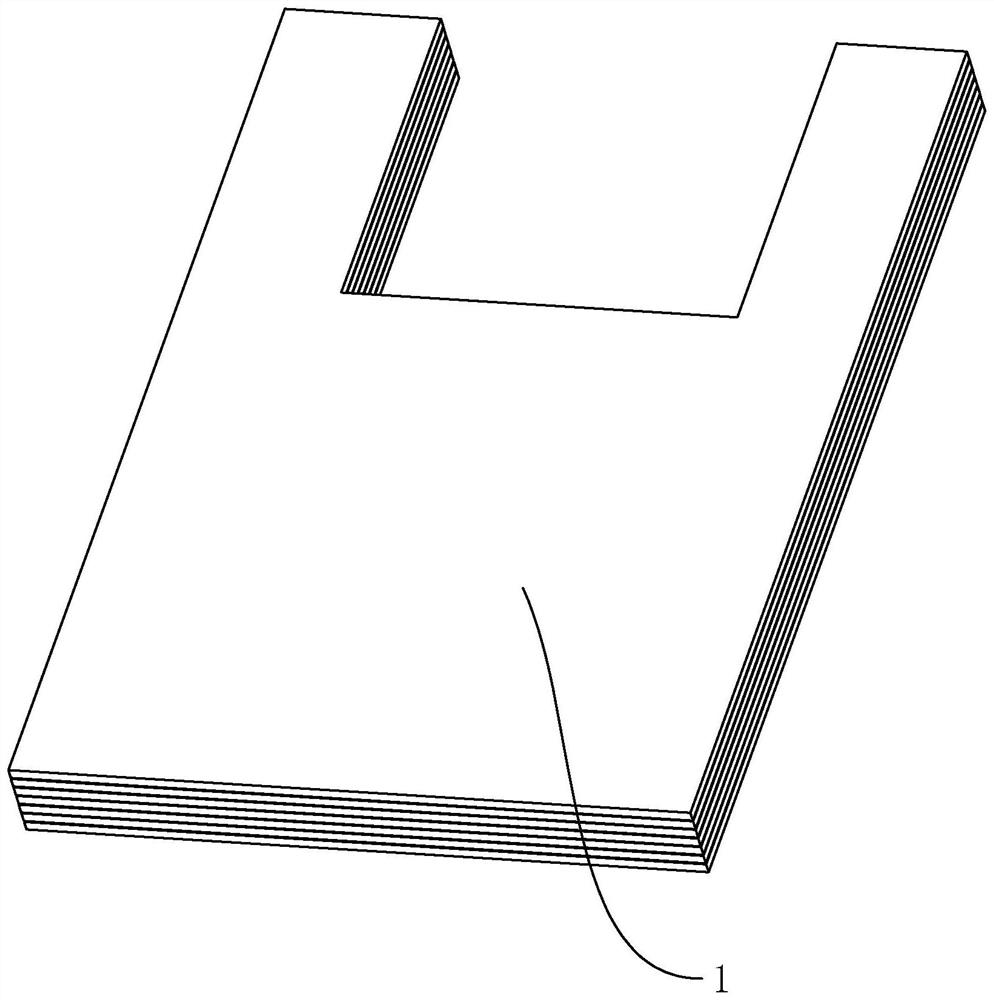

A production process of the back panel of the backpack

ActiveCN111041713BAffects air permeabilityPrevents impact on breathabilitySevering textilesNon-woven fabricsMechanical engineeringIndustrial engineering

The invention discloses a production process of a back piece of a backpack, relates to a backpack and aims to solve the problem of lack of breathability. The technical scheme of the production processof the back piece of the backpack is characterized by comprising steps as follows: S1, Dupont sorona fiber is carded in a thin net state through a roller carder and sent into a net paving machine onstandby, oyster fiber mixed hot-melt short fiber is carded in a thin net state by a roller carder, sent into the net paving machine and paved above sorona fiber, and a fiber net with 10-40 g / m<2> is prepared from the paved net and finally coiled to form a fiber net; S4, an inner-core blank is sent into a hot cutting press and is cut into a required appearance by a hot cutting die of the hot cutting press, and a filling inner core is prepared; and S5, the filling inner core is wrapped with fabric, and the back piece of the backpack can be made. By means of the production process of the back piece of the backpack, the breathability of the back piece of the backpack is effectively improved, so that the sweating capability is improved, and the hidden danger of breeding of bacteria is further reduced.

Owner:孙福胜 +1

Breeding method of japonica photoperiod/thermo-sensitive genic male sterile lines

InactiveCN101999302BFacilitates fertility control and sterility selectionEliminate the phenomenon of genetic driftPlant genotype modificationRice cultivationAnimal scienceGreenhouse

Owner:INST OF FOOD CROPS HUBEI ACAD OF AGRI SCI

Artificial synthetic feed containing leek maggot

InactiveCN101433276BImprove survival rateHigh reproductive rateAnimal feeding stuffYeastAnimal science

The invention relates to artificial synthetic feed, in particular to artificial synthetic feed of chive maggot. The feed consists of mushroom powder taken as a main composition and yeast powder as an auxiliary material. The feed with the mixture ratio is used to feed the chive maggot; the survival rate, the pupation rate, the eclosion rate and the egg laying amount of a single female are quite close to the chive maggot fed by natural feed; and the average pupae weight of male and female is higher than the chive maggot fed by natural feed, thereby favorable condition for normal supply for the tested chive maggot.

Owner:INST OF PLANT PROTECTION SHANDONG ACAD OF AGRI SCI

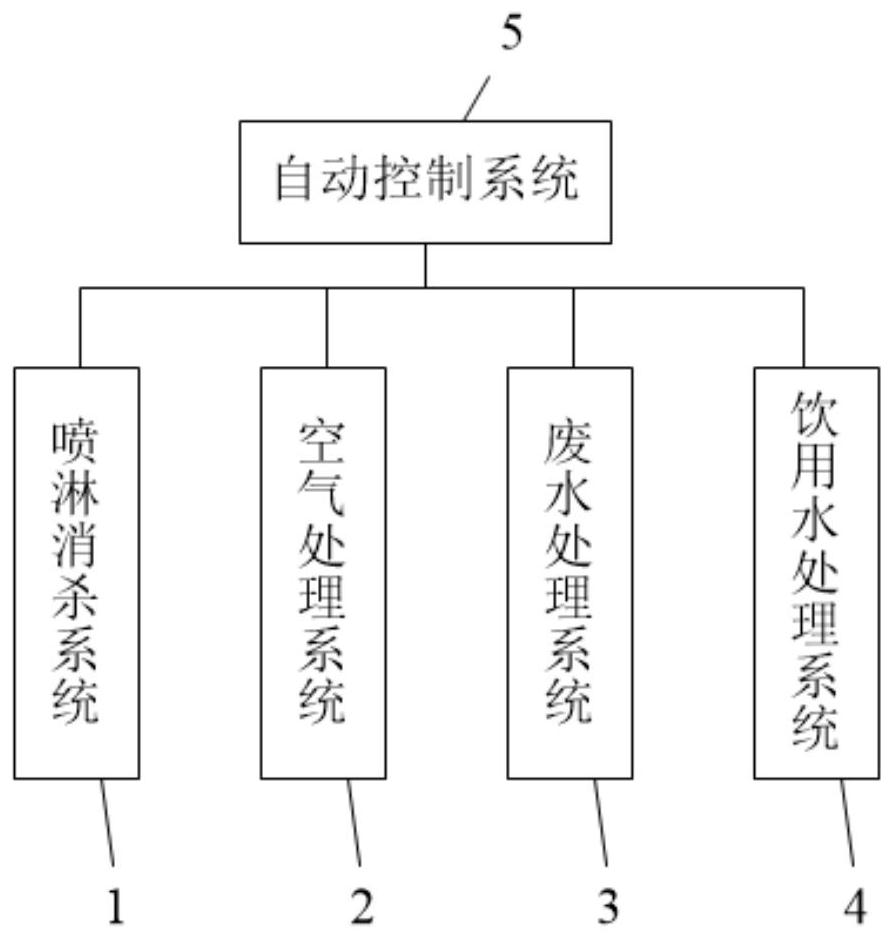

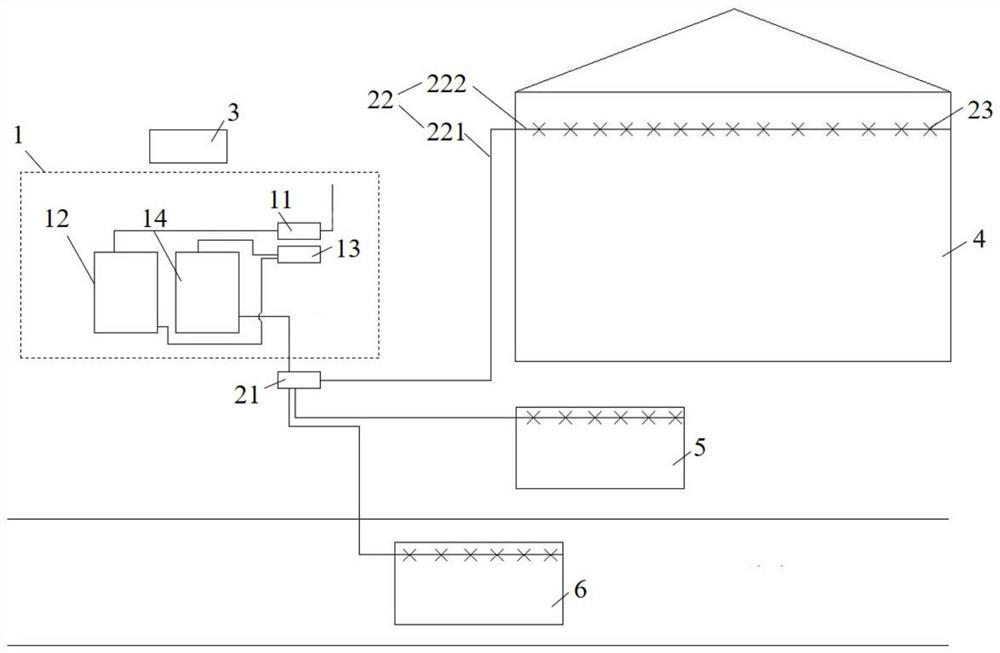

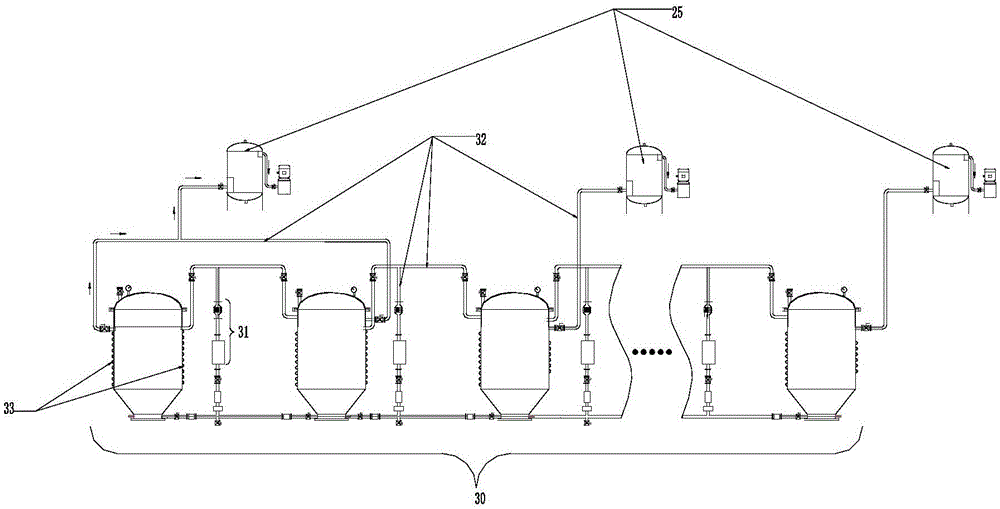

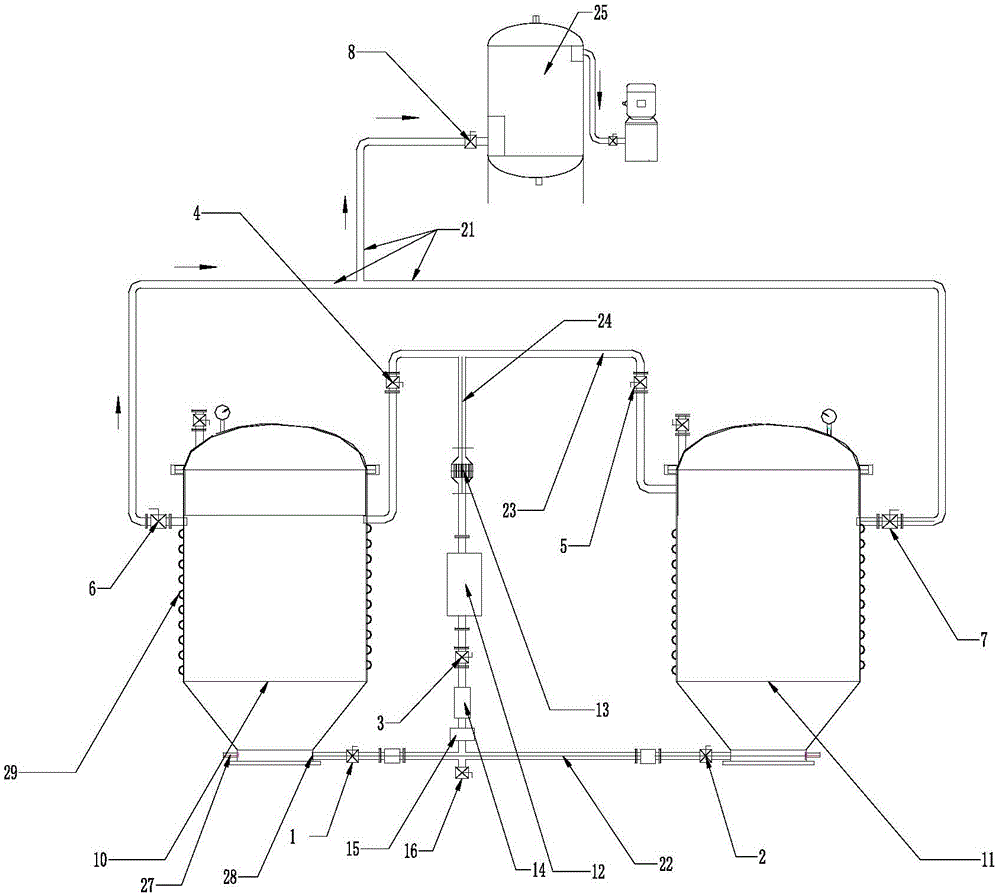

Electrolyzed water disinfection system for livestock and poultry breeding

PendingCN112337290AEfficient purificationEfficient disinfection and sterilizationAnimal watering devicesWaste water treatment from animal husbandryAutomatic controlWater treatment system

The invention discloses an electrolyzed water disinfection system for livestock and poultry breeding. The electrolyzed water disinfection system comprises a spraying disinfection system, an air treatment system, a wastewater treatment system, a drinking water treatment system and an automatic control system. The spraying disinfection system, the air treatment system, the wastewater treatment system and the drinking water treatment system can be controlled through the automatic control system; therefore, comprehensive and automatic spraying disinfection treatment in a culture plant area is realized, air in a farm is effectively purified, the farm is cooled, wastewater is purified, disinfected and disinfected, drinking water is effectively sterilized and disinfected, and safe and healthy livestock and poultry drinking water is provided.

Owner:广东原之生农业科技有限公司

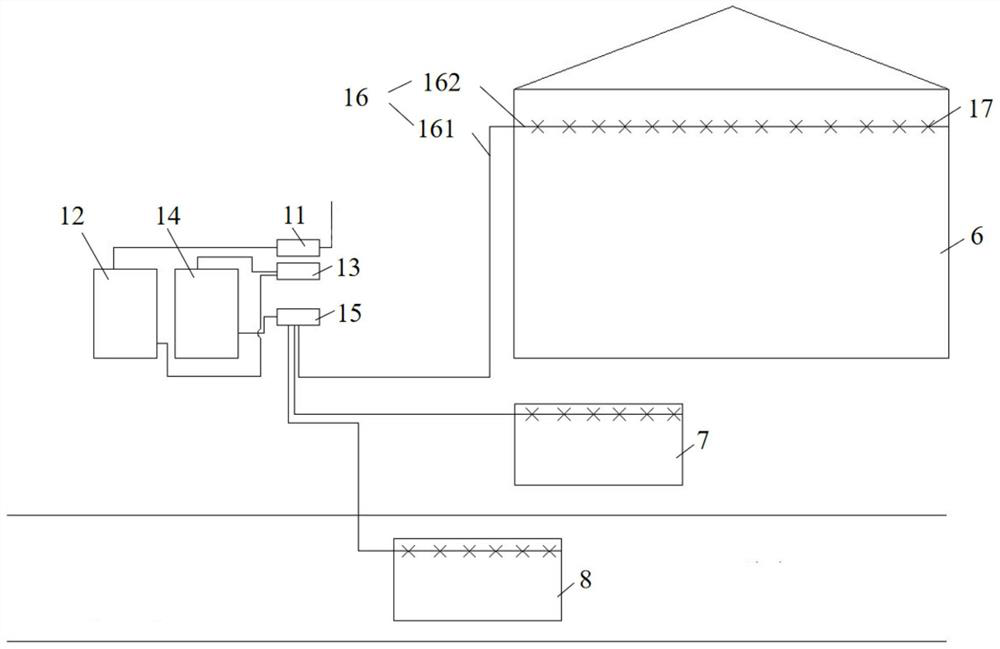

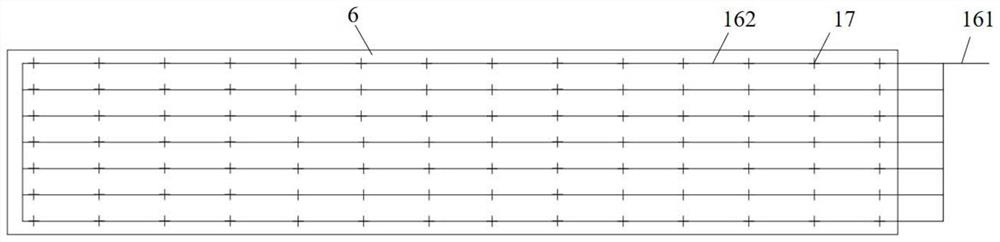

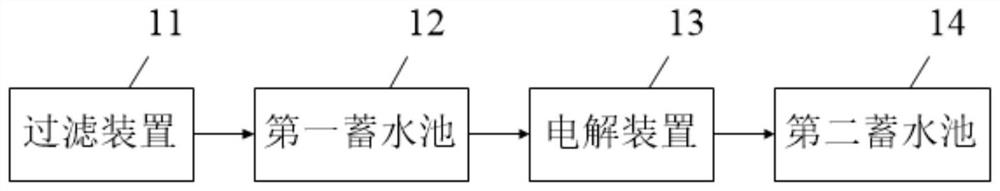

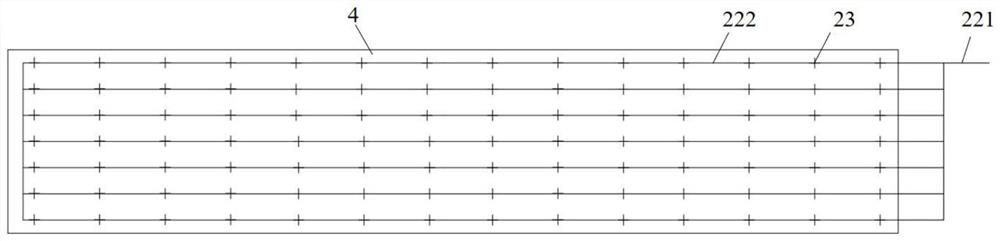

Net distribution type spraying disinfection and sterilization system

PendingCN112220940ARealize comprehensive disinfection treatmentWith self-cleaning functionHollow article cleaningLavatory sanitoryElectrolysed waterWater storage tank

The invention discloses a net distribution type spraying disinfection and sterilization system. The net distribution type spraying disinfection and sterilization system comprises an electrolyzed watergeneration system, a spraying pipeline system and an automatic control system, wherein the electrolyzed water generation system comprises a filtering device, a first water storage tank, an electrolyzing device and a second water storage tank which are sequentially connected through pipelines; the spraying pipeline system comprises a spray generating device, spraying pipelines and atomizing nozzles; the spraying pipelines comprise main pipelines for conveying disinfectant fluid and branch pipelines arranged in a farm, a personnel disinfection area and a vehicle disinfection area; each branch pipeline communicates with the corresponding main pipeline; and the atomizing nozzles are arranged on the branch pipelines. By the adoption of the net distribution type spraying disinfection and sterilization system, the net distribution type spraying disinfection and sterilization system which is high in safety and good in sterilization effect can be obtained, the net distribution type spraying disinfection and sterilization system can achieve comprehensive and automatic spraying disinfection and sterilization treatment in a breeding plant area, and therefore the effects of sterilization and disinfection and disease breeding risk reduction are achieved.

Owner:广东原之生农业科技有限公司

A kind of fully synthetic environment-friendly cutting fluid for aluminum alloy processing and preparation method thereof

The invention belongs to the technical field of metal processing. More specifically, the invention relates to a fully synthetic environment-friendly cutting fluid for aluminum alloy processing and a preparation method thereof. A fully synthetic environment-friendly cutting fluid for aluminum alloy processing, comprising the following components in parts by weight: 5-25 parts of ammonium carboxylate compound antirust agent, 5-30 parts of sulfonated castor oil, 2-2 parts of water-soluble lubricant 15 parts, 1-6 parts of monobasic acid, 0.5-2 parts of anti-mold and fungicide, 0.02-1 part of defoamer, 20-55 parts of water. The invention provides a kind of fully synthetic environment-friendly cutting fluid for aluminum alloy processing, which is compounded with sulfonated castor oil and water-soluble lubricant to provide high lubricating performance. As an oil-free cutting fluid product, it can replace low oil content under the same conditions In addition, the invention protects the aluminum alloy from discoloration through the compounding of ricinoleic acid, organic acid and special alcohol amine, and solves the high lubrication requirements in the process of aluminum alloy processing.

Owner:GUANGZHOU LANDNOK CHEM TECH

Heat exchanger, in particular a flat pipe evaporator for a motor vehicle air conditioning system

InactiveCN100565079CReduce savingsReduce the risk of sprayingSafety devices for heat exchange apparatusClosure meansAutomobile air conditioningEngineering

The invention relates to a heat exchanger, in particular a flat tube evaporator (1) for a vehicle air-conditioning unit, having at least one collecting tank (2) made of plate material, which is divided longitudinally into at least two chambers , while the tubes, especially the ends of the flat tubes, are inserted into the bottom of the collecting tank. Said collecting tank (2) has a tunnel-shaped collecting tank part (5), a substantially flat collecting tank part (4) forming the bottom of the collecting tank, and caps ( 6). At least one cover (6) is flat in the region of its outer edge and is positively positioned in the collecting tank.

Owner:BEHR GMBH & CO KG

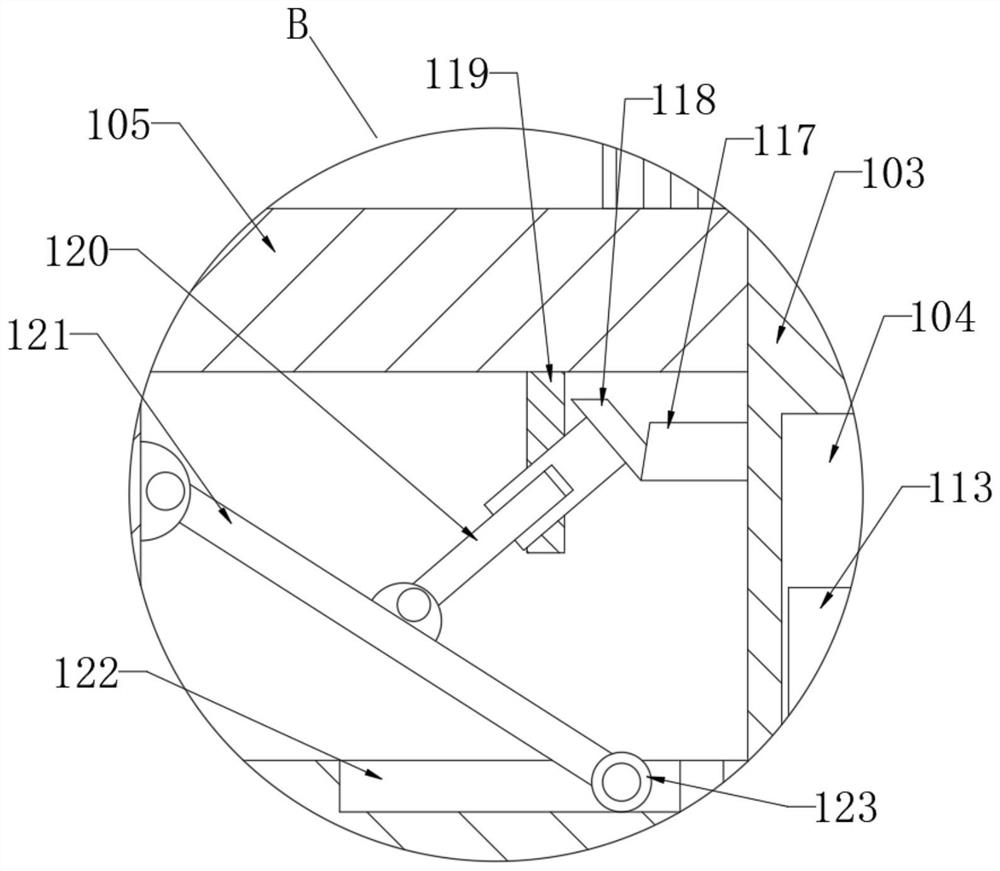

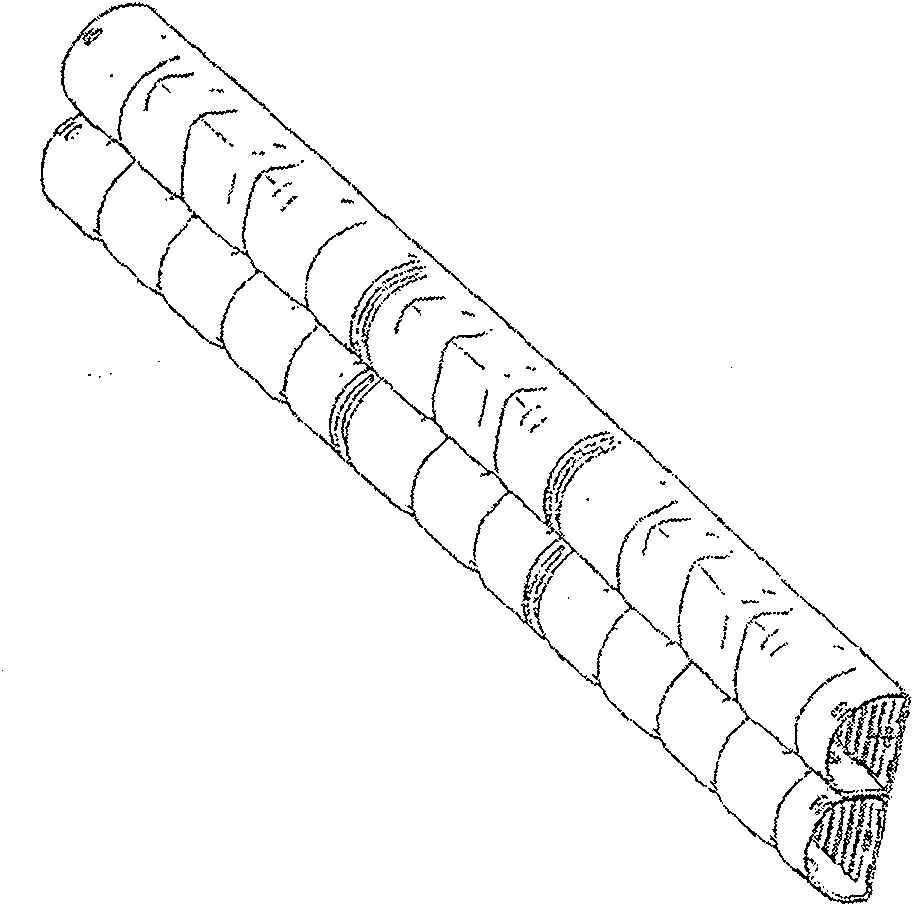

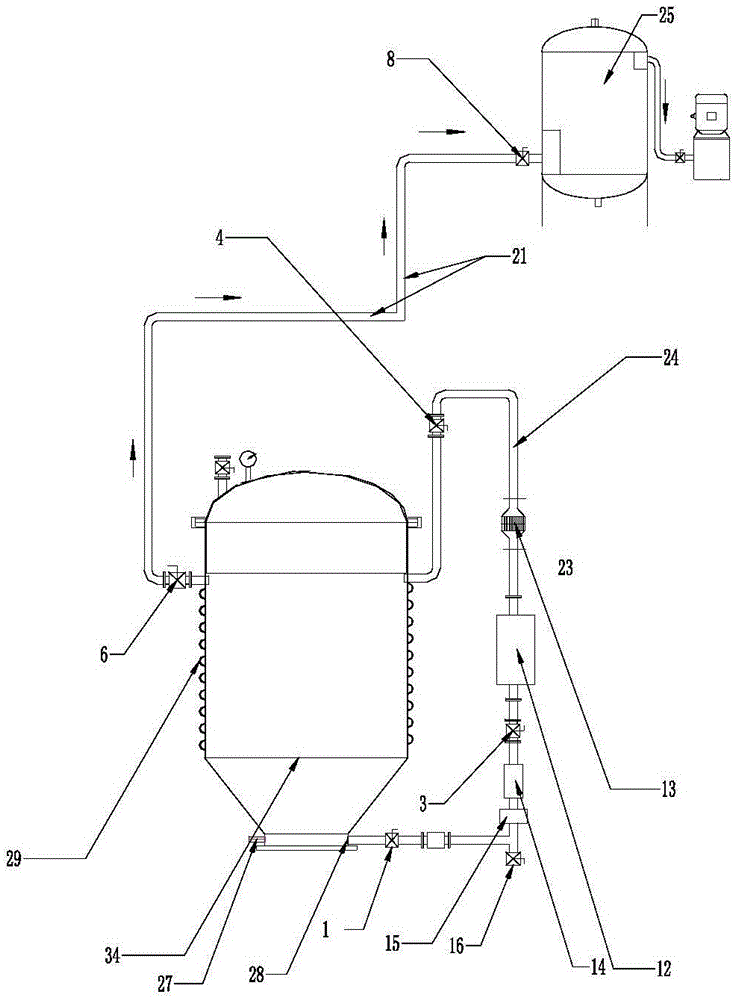

Vacuum electromagnetic betel nut impregnation system

InactiveCN105309902AAchieve circular flowGuaranteed uniformityFood preparationFood treatmentElectromagnetic launchBetel

The invention belongs to the technical field of food impregnation and flavoring equipment, and particularly relates to a vacuum electromagnetic betel nut impregnation system. The vacuum electromagnetic betel nut impregnation system comprises a vacuum electromagnetic impregnation tank set, a pipeline system, a vacuum system, an emulsification system and an electromagnetic system. The upper portions of vacuum electromagnetic impregnation tanks of the vacuum electromagnetic impregnation tank set are connected with an upper circulation pipeline. The bottoms of the vacuum electromagnetic impregnation tanks are connected with a lower circulation pipeline. The upper circulation pipeline and the lower circulation pipeline are connected through a liquid return pipe. The upper portions of the vacuum impregnation tanks are connected with a vacuum system through a vacuum pipe. Valves are arranged at the joint of pipelines in the pipeline system and vacuum electromagnetic impregnation tanks to control the pipelines to be on or off. The electromagnetic system is composed of electromagnetic transmitters wound round the inner walls of the vacuum electromagnetic impregnation tanks. The vacuum electromagnetic betel nut impregnation system is simple in composition, short in betel nut impregnation time, convenient to operate, uniform in betel nut flavoring and good in quality. The system can be used for betel nut impregnation and flavoring and can also be used for vacuum adjusting and flavoring of other foods.

Owner:HUNAN ONYEAR FOOD

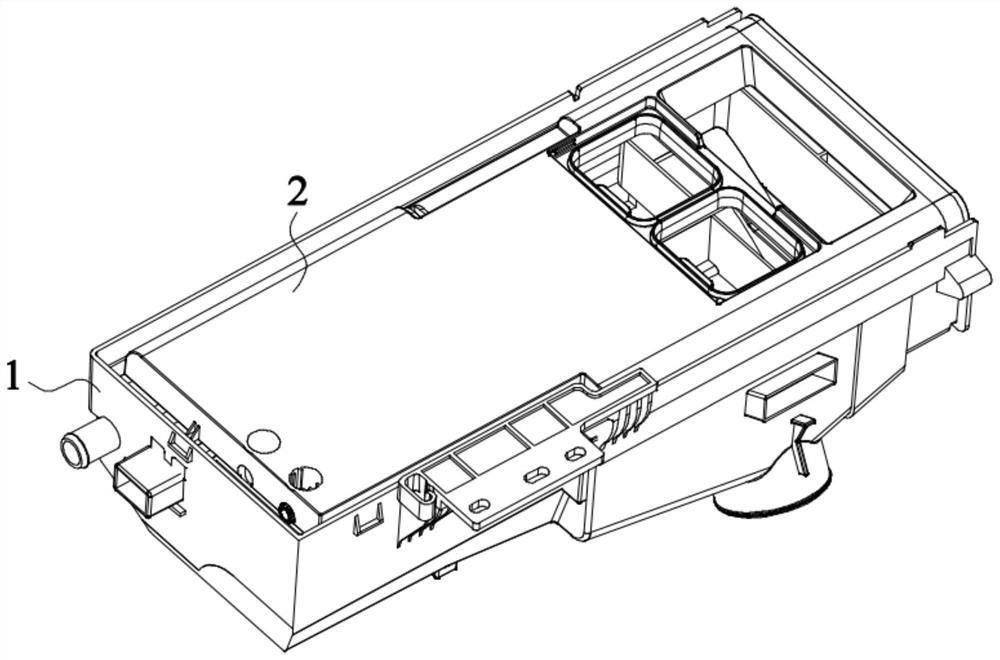

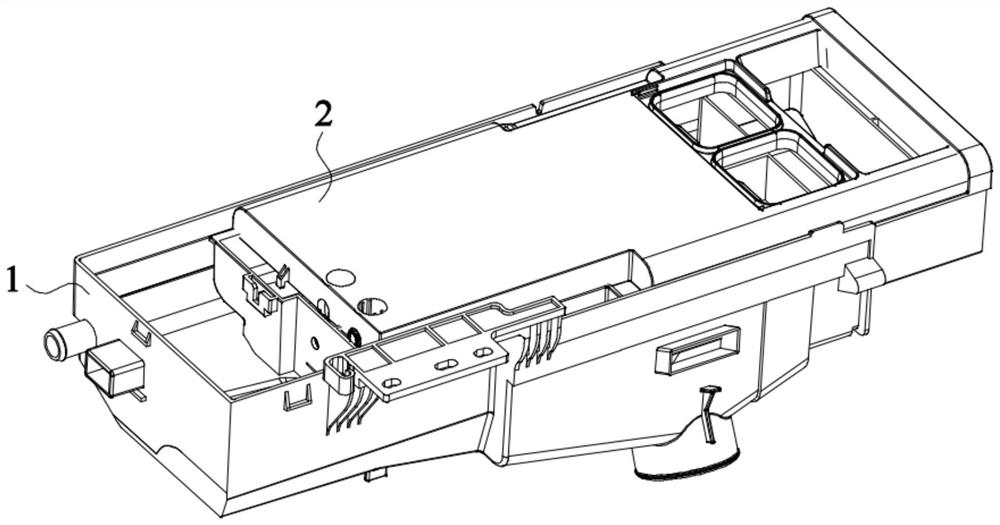

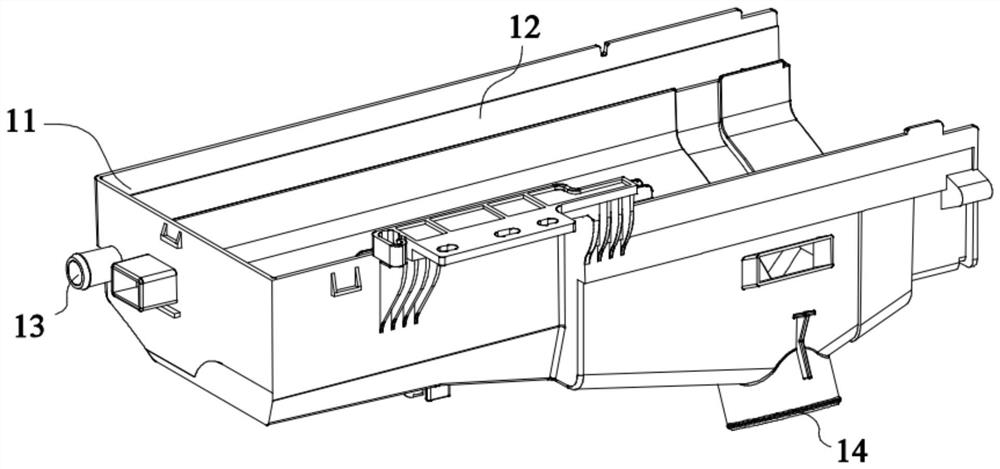

Detergent feeding device and washing machine

ActiveCN108193442BShorten the timeReduce material costsOther washing machinesTextiles and paperLaundry washing machineProcess engineering

The invention relates to the technical field of washing devices, and discloses a detergent release device which comprises an outer box, an inner box and liquid pumps. The inner box can be pushed intoouter box or can be pulled out of the outer box; the liquid pumps are used for pumping liquid in the inner box into the outer box, and shells of the liquid pumps and the inner box are of integral structures. The invention further discloses a washing machine. The washing machine comprises the detergent release device. The detergent release device and the washing machine have the advantages that theshells of the liquid pumps and the inner box are integrated with one another, accordingly, required assembling time can be saved, components can be reduced, and the material cost can be lowered; clean washing machine use procedures can be implemented, and accordingly mildew breeding risks can be reduced; the release precision can be improved, and accordingly washing procedures are safe and reliable.

Owner:NANJING ZHONGJINGKE ELECTRONICS TECH

Breathable waterproof multifunctional grid protective clothing

ActiveCN112956761ACapable of reabsorbing waterPromote absorptionProtective garmentSpecial outerwear garmentsSuction forceWater vapor

The invention discloses breathable waterproof multifunctional grid protective clothing and belongs to the field of protective clothing. The breathable waterproof multifunctional grid protective clothing can effectively absorb water vapor generated in the protective clothing through the cooperative effect of inner suction breaking balls and transverse water collecting balls, and after the protective clothing is worn for a long time, the water vapor can be effectively absorbed; a worker can manually keep away from the transverse water collecting ball to press the protective clothing body, on one hand, water absorbed in the protective clothing body is squeezed out and then flows out to be absorbed by the transverse water collecting ball, the inner suction breaking ball has the effect of absorbing water again, and the absorption capacity of the interior of the protective clothing to water vapor generated by the human body is remarkably improved; on the other hand, when the inner suction breaking ball is pressed, the inner breaking ball is broken, the extrusion force on the inner pressure water absorption ball is relieved, the inner pressure water absorption ball is expanded, the water absorption performance is improved, and then the water absorption performance reduced by part of residual water vapor is effectively made up.

Owner:海南科颜纳生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com