Heat exchanger, in particular a flat pipe evaporator for a motor vehicle air conditioning system

A technology of heat exchangers and flat tubes, applied in the field of flat tube evaporators, can solve problems affecting the water storage and discharge performance of evaporators, and achieve the effects of reducing the risk of sudden fogging, increasing power potential, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

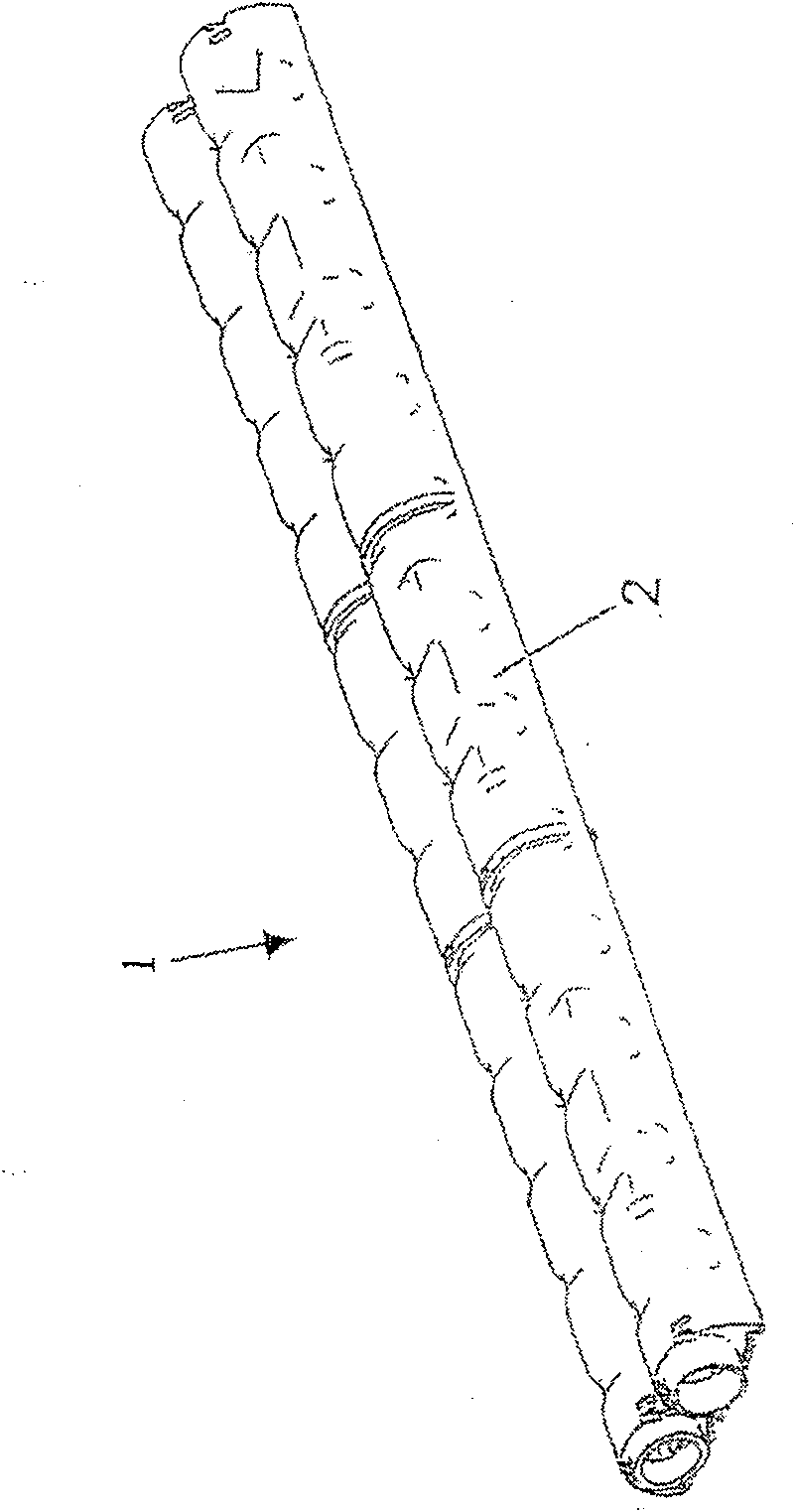

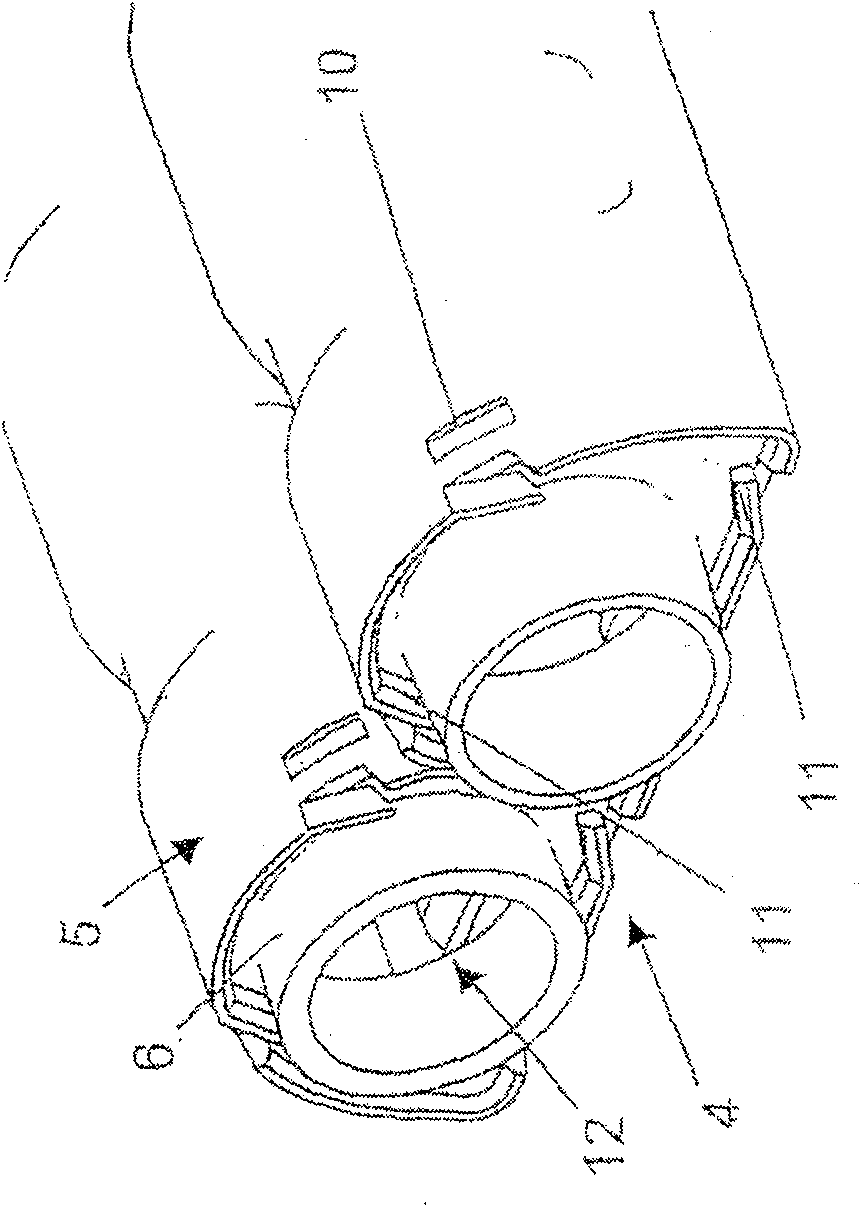

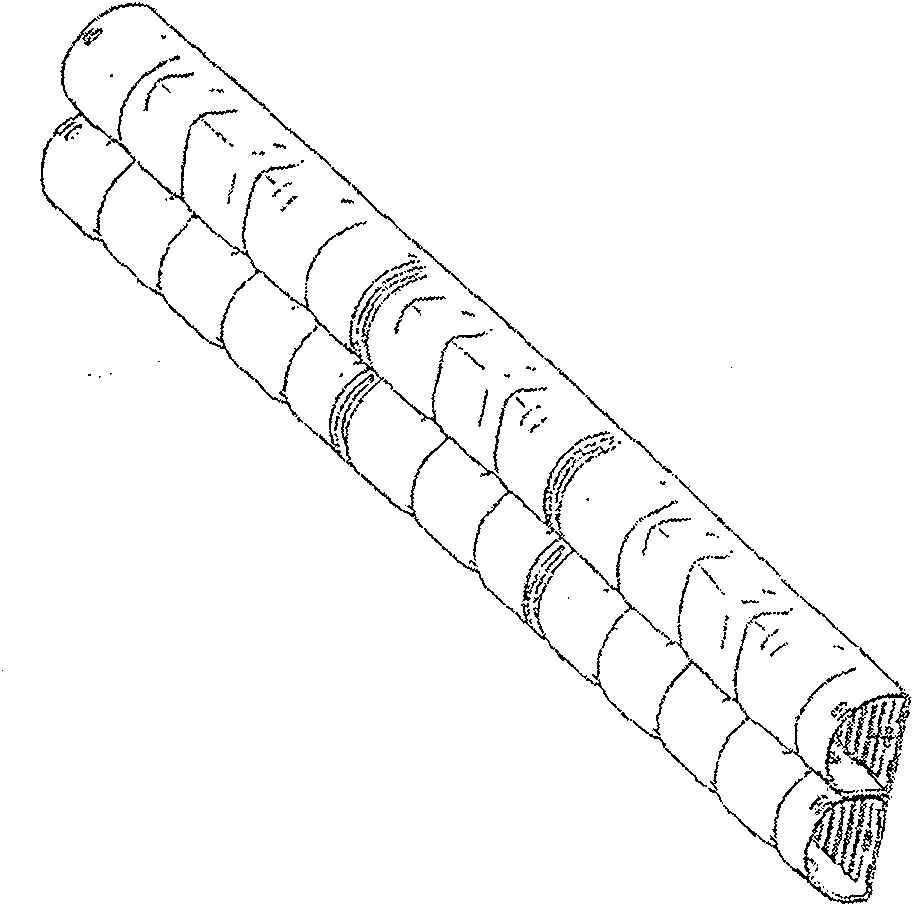

[0045] As previously described in DE198 26 881 A1, the flat tube evaporator 1 of automobile air conditioning equipment (only a part in the figure) includes two collecting boxes 2 and flat tubes (not shown) between the two collecting boxes 2 and corrugated fins 3 arranged between the flat tubes. According to this embodiment, each collecting tank 2 is formed by a slab stamped from sheet material, and the slab forms a flat collecting tank part 4 and two tunnel-shaped Collecting box part 5 (see Figure 4 and 6 ). Its longitudinal edge is provided with a plurality of tabs distributed over its length, which are inserted into openings in the flat collecting tank part 4 and caulked on the outside facing the flat tube. The ends are closed by caps 6 which will be described in detail later.

[0046] A plurality of flange holes 7 are formed in the flat collecting tank part 4 , into which the flat tubes are inserted, wherein the shape of the openings of the flange holes 7 substantially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com