Wet granulation production system and use method

A technology of wet granulation and production system, which is applied in the direction of making medicines into special physical or ingestible forms, such as devices, applications, and drying of granular materials, which can solve the problems of high equipment manufacturing costs and use costs, unfavorable parallel production, and work Low efficiency and other problems, to achieve the effect of reducing manufacturing cost and use cost, reducing the risk of bacterial growth, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

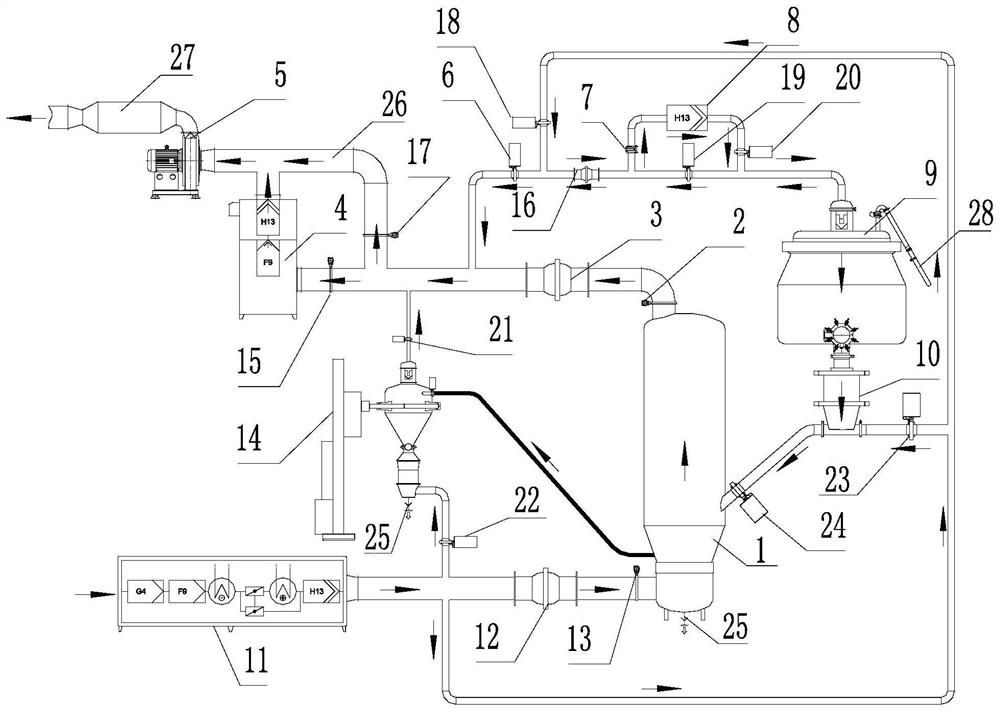

[0034] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0035] figure 1 An embodiment of the wet sheet production system of the present invention is shown. The wet granulation production system of the present embodiment includes a wet granulator 9, a wet meter 10, a fluidized bed disposed in the transport direction of the material transport. 1 and the hierarchy 14, further comprising the ventilation assembly 11 and the exhaust assembly 5, the wet sheeter 10, the fluidized bed 1, and the lift unit 14 are connected to the air opening of the air supply assembly 11 through the pipeline. The wet granulator 9 is provided with a suction member 28, a wet granulator 9, a fluidized bed 1, and a lifting machine 14 to be connected to the air opening of the exhaust assembly 5 through the pipeline. Among them, the suction member 28 can, for example, be a suction gun or the like.

[0036] The wet sheet produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com