Reverse osmosis membrane filter element flushing system, reverse osmosis system and water purifier

A technology of reverse osmosis membrane and flushing system, which is applied in the direction of osmosis/dialysis water/sewage treatment, reverse osmosis, semi-permeable membrane separation, etc., and can solve the problem of incomplete flushing of reverse osmosis membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

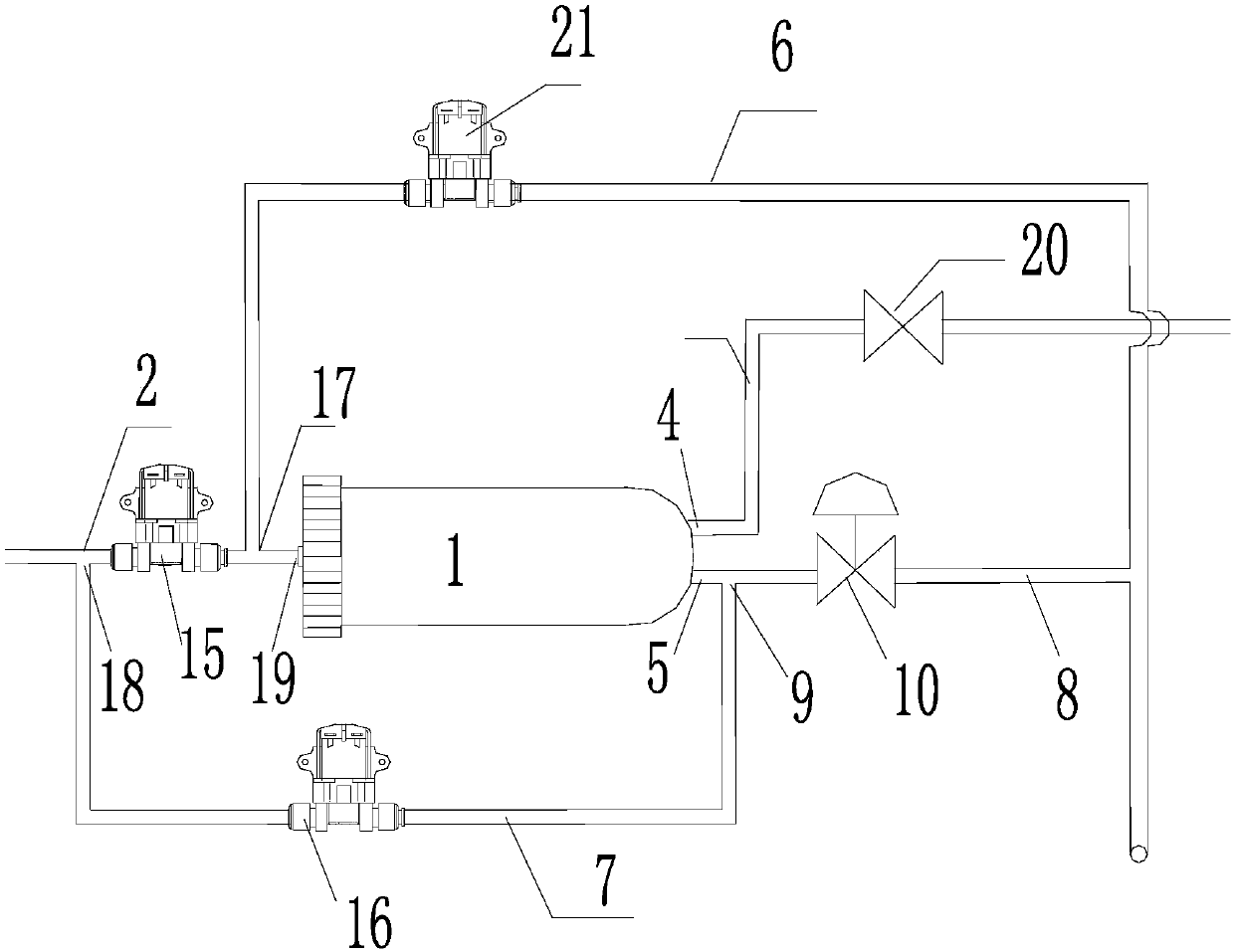

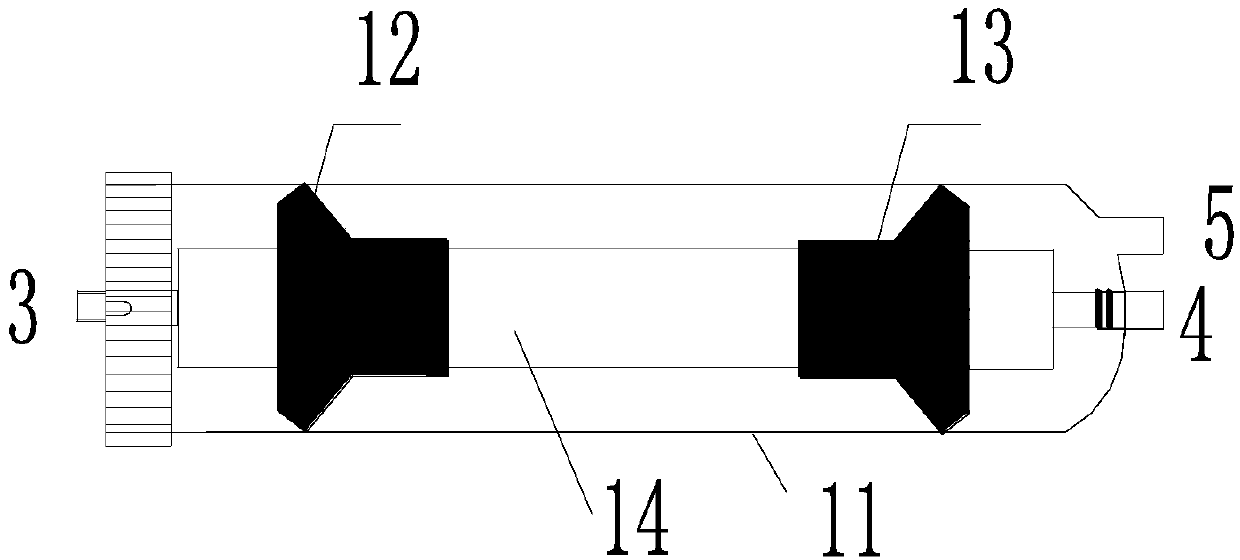

[0032] This embodiment provides a reverse osmosis membrane filter element flushing system, such as figure 1 As shown, it includes: a reverse osmosis membrane filter element 1, which includes: a water inlet 19 connected to the water inlet pipe 2; a clean water outlet 4 for clean water to flow out; and a concentrated water outlet 5 for concentrated water to flow out; flushing water can pass through the The concentrated water inlet 5 flows into the inside of the reverse osmosis membrane filter element 1 , and is discharged through the water inlet 19 after the reverse osmosis membrane filter element 1 is washed.

[0033] The flushing method of the reverse osmosis membrane in the prior art will cause the scale of the reverse osmosis membrane to start from the water production end, such as carbonate and other inorganic salt scales, etc., and gradually expand to the water inlet end, and finally the entire membrane surface is covered. Full of dirt, the life of the reverse osmosis memb...

Embodiment 2

[0042] This embodiment provides a reverse osmosis system, comprising: the flushing system described in Embodiment 1; a water purification pipe, one end of which is connected to the water purification port, and the other end is connected to the water storage tank; a primary purification module is connected to the The end of the water inlet pipe away from the water inlet is used for primary purification of flushing water.

[0043] Specifically, the primary purification module is a primary purification module, such as activated carbon.

Embodiment 3

[0045] This embodiment provides a water purifier, including the reverse osmosis system described in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com