Detergent and its preparation method and application

A technology of detergent and cellulose, which is applied in the field of daily chemical products, can solve the problems of slow draining rate, water marks and spots on the surface, so as to improve the draining rate and reduce water marks and spots on the surface of tableware The production and the effect of realizing industrialized large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

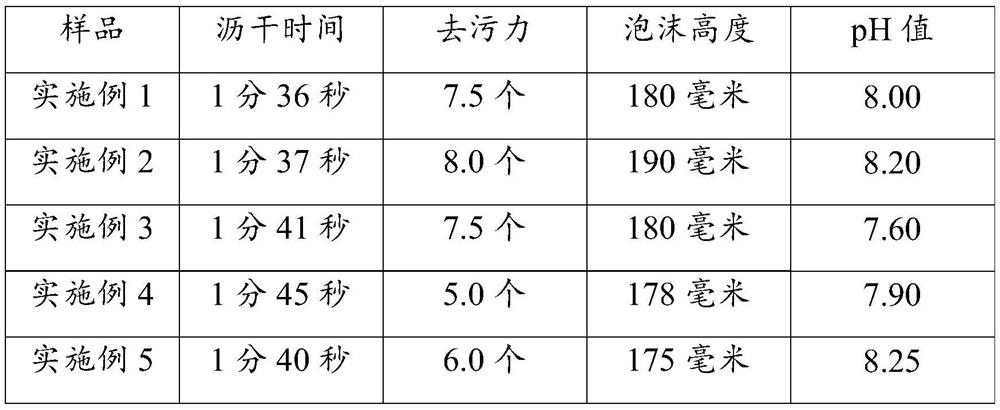

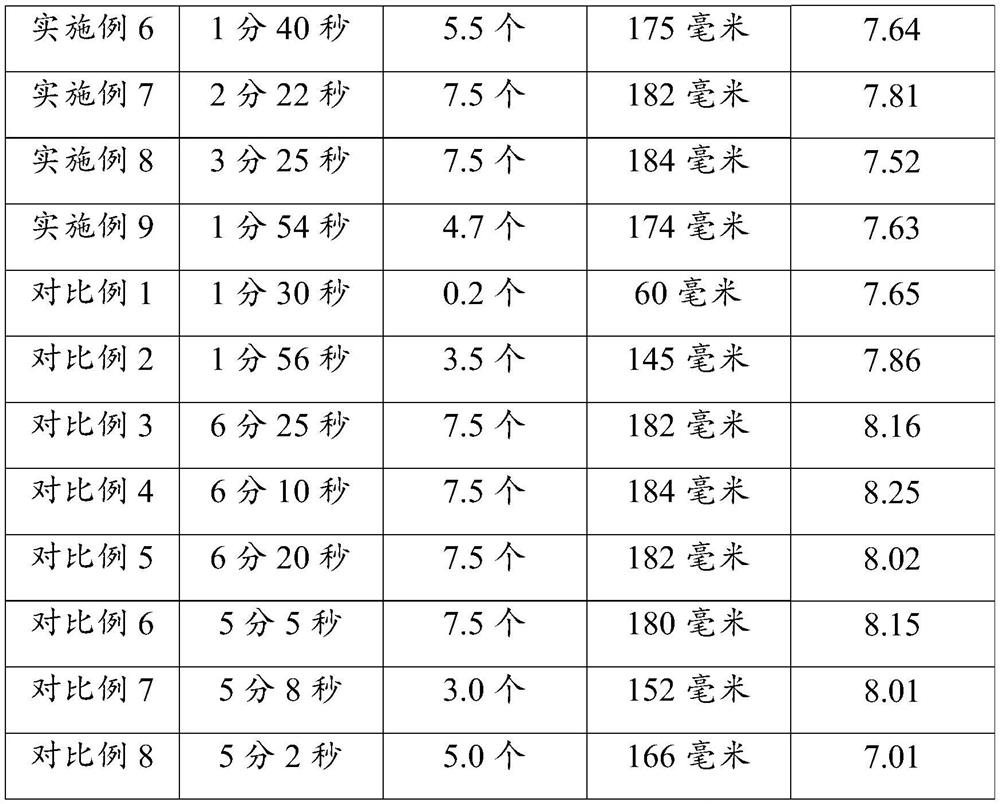

Examples

Embodiment approach

[0096] As a preferred embodiment of the present invention, the dishwashing liquid comprises the following components by weight percentage:

[0097] Anionic surfactant 5-40%, zwitterionic surfactant 0.5-15%, nonionic surfactant 0.1-2.0%, cellulose composition 0.05-1.0%, chelating agent 0.01-0.1%, preservative 0.01-0.5% % and viscosity modifier 0.01-5.0%, the balance is water (water makes up 100%);

[0098] Wherein, the cellulose composition is mainly composed of the following components in weight percentage: 90-99.8% of cationic hydroxyethyl cellulose, 0.1-5.0% of sodium acetate and 0.1-5.0% of isopropanol.

[0099] As another preferred embodiment of the present invention, the dishwashing liquid comprises the following components by weight percentage:

[0100] Anionic surfactant 5-40%, zwitterionic surfactant 0.5-15%, cellulose composition 0.05-1.0%, chelating agent 0.01-0.1%, preservative 0.01-0.5% and viscosity regulator 0.01-5.0%, Surplus is water (water makes up 100%);

...

Embodiment 1

[0113] A kind of liquid detergent, comprises the following components by weight percentage:

[0114] Sodium Linear Alkylbenzene Sulfonate 4.0%, Sodium Ethoxylated Alkyl Sulfate 10.0%, Cocamidopropylamine Oxide 7.5%, Fatty Amidopropyl Betaine 2.5%, Cellulose Composition 0.5%, Chelating Agent 0.05%, preservative 0.03%, viscosity regulator 0.5%, water balance.

[0115] Wherein, the cellulose composition is mainly composed of the following components in weight percentage: 95% of cationic hydroxyethyl cellulose, 1.5% of sodium acetate and 0.5% of isopropanol.

Embodiment 2

[0117] A kind of liquid detergent, comprises the following components by weight percentage:

[0118] Sodium Linear Alkylbenzene Sulfonate 8.5%, Sodium Ethoxylated Alkyl Sulfate 6.5%, Cocamide Alkylamine Oxide 1.5%, Fatty Amidopropyl Betaine 0.5%, Alkyl Polyglucoside 1.0%, Fiber Vegetable composition 0.5%, chelating agent 0.05%, preservative 0.03%, viscosity modifier 1.0%, water balance.

[0119]Wherein, the cellulose composition is mainly composed of the following components in weight percentage: 95% of cationic hydroxyethyl cellulose, 1.5% of sodium acetate and 0.5% of isopropanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com